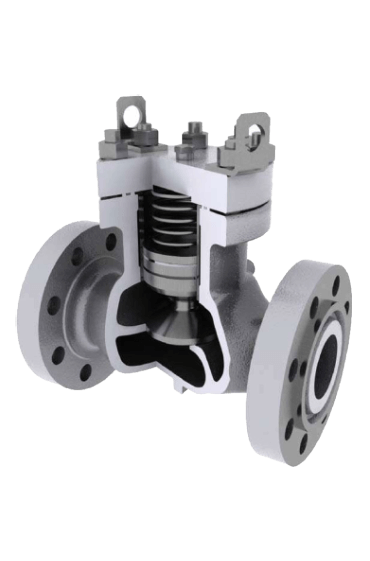

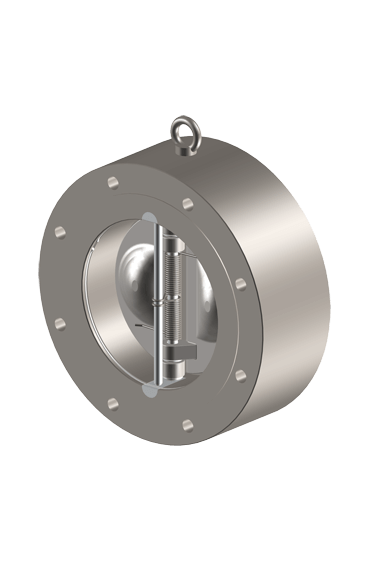

A dual plate check valve is a type of non-return valve that uses two spring-loaded plates to allow flow in one direction and prevent backflow in the opposite direction.

Dual Plate Check Valve

Don't Gamble with Backflow: Trust the Strength of Freture's Dual Plate Check Valves.

As a Dual Plate Check Valve manufacturer in Mumbai, India with years of experience in industrial processes, Freture offers a smarter, upgraded solution for industrial needs. Our unique dual plate check valve design utilizes two spring-loaded discs that hinge for effortless forward flow. These plates are hinged and spring-loaded, allowing fluid to pass through in one direction while sealing shut to prevent backflow when the pressure changes.

Freture's dual plate check valves are known for their numerous advantages. We provide a compact and lightweight solution compared to other check valves, and our design minimizes pressure loss and water hammer, protecting your equipment and ensuring silent operation. Dual plate check valves are a popular choice in plumbing applications, industrial processes, and various other settings, as they can be mounted in any orientation and require minimal maintenance.

Specifications | Features |

|---|---|

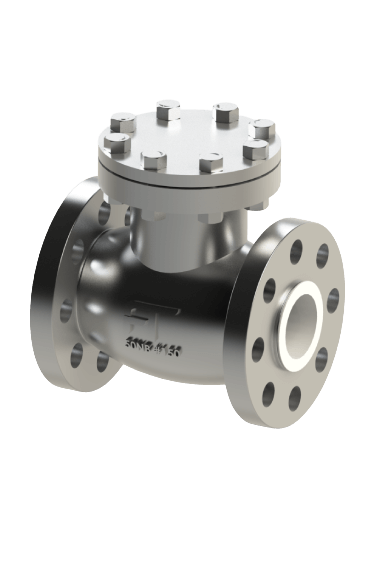

Type: Dual Plate Check Valve End Connection: Wafer, Lug, Flanged (ASME B16.5 / B16.11 / B16.25 / ANSI 1.20.1) Size: 15NB - 600NB Class: 150# - 600# Temperature: -20° C to 200° C Material: Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel Design Standard: API 6D / API 602 / API 594 Compliance: AWWA, ANSI, NSF Seat: Nitrile, EPDM, or Viton (metal-to-Metal, soft-seated) Safety: BS / EN, NACE, API 598 Rev 2009, API 607 Rev 2010 | Compact Design: Slim and lightweight, saving space. Low Pressure Drop: Minimizes pressure loss for efficient fluid flow. Non-Slam Operation: Prevents water hammer with smooth closure. Bi-Directional Flow: Allows fluid flow in both directions. Spring-Assisted Closure: Enhances response time and reliability. Wide Applications: Suitable for water treatment, oil and gas, petrochemical, and HVAC systems. Silent Operation: Minimizes noise during operation. Low Maintenance: Few moving parts, reducing maintenance needs and costs. Corrosion Resistance: Offers excellent resistance to harsh environments. |

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a dual plate check valve?

- How does a dual plate check valve work?

The valve opens when fluid flows in the correct direction, pushing the plates apart. When the flow stops or reverses, the spring mechanism closes the plates, preventing backflow.

- What are the advantages of using a dual plate check valve?

Advantages include a compact design, lightweight, low pressure drop, fast response to flow changes, and suitability for both horizontal and vertical installations.

- In which industries are dual plate check valves commonly used?

They are commonly used in water treatment, oil and gas, petrochemical, power generation, and HVAC industries.

- Can dual plate check valves be used in both horizontal and vertical installations?

Yes, dual plate check valves can be installed in both horizontal and vertical pipelines, although vertical installation is typically with upward flow.

- What materials are dual plate check valves made from?

Common materials include cast iron, ductile iron, carbon steel, stainless steel, and special alloys for specific applications.

- How do I choose the right dual plate check valve for my application?

Consider factors such as the fluid type, pressure and temperature conditions, flow rate, and the required end connection type when selecting a valve.

- What are the maintenance requirements for dual plate check valves?

Dual plate check valves generally require minimal maintenance. Regular inspections and cleaning may be necessary to ensure proper operation and to remove any debris.

- Are there any standards for dual plate check valves?

Yes, dual plate check valves are designed and manufactured according to standards such as API 594, API 6D, and ASME B16.34

- why choose freture technno to buy it from

Many industries have chosen Freture Techno for our superior design that meets industry standards, matching their needs in terms of performance and efficiency. With great customer support, we confidently address your requirements.

If you have similar needs, you can confidently rely on us.

Industries where Dual Plate Check Valve is Used

Oil And Gas

Water Treatment

Petrochemical Industry

Power Generation

HVAC System

Applications of Dual Plate Check Valve

- Pump Discharge Lines: Prevents backflow to protect pumps.

- Water Distribution Systems: Ensures one-way flow in supply pipelines.

- Cooling Systems: Prevents reverse flow in HVAC and industrial cooling.

- Fire Protection Systems: Maintains pressure and prevents backflow in sprinkler systems.

- Chemical Processing: Prevents contamination in chemical transport pipelines.