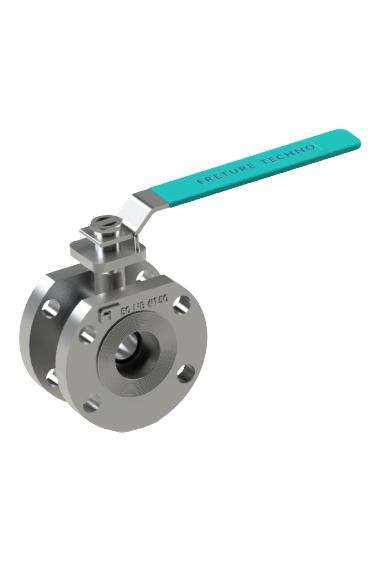

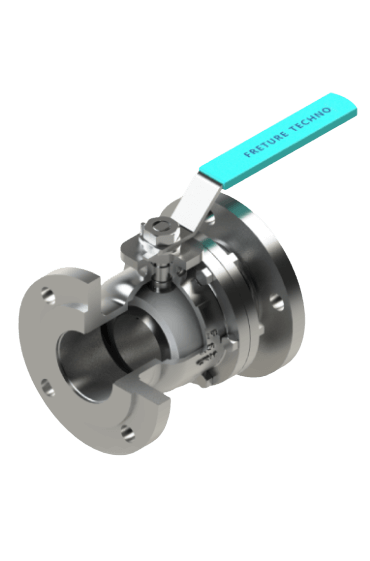

A Cavity Filler Ball Valve is designed to eliminate cavities in the valve body, preventing fluid accumulation and contamination, making it ideal for sanitary and clean applications.

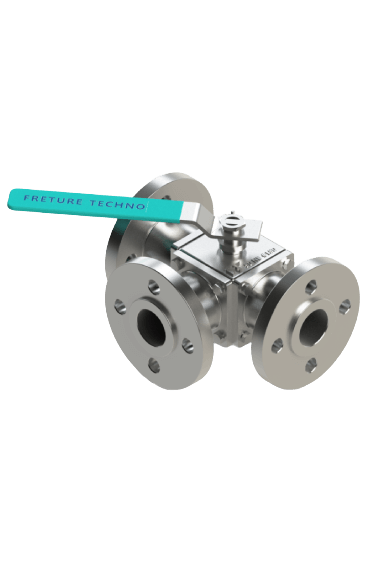

Cavity Filler Ball Valve

Cavity Filler Ball Valves are offer improved efficiency in any kind of setting.

We are a leading cavity Filler Ball Valve manufacturer in Mumbai, India. This type of valve works well for any kind of medium, making it the go-to option for factories and plants that deal with a variety of media. Be it liquid, semi-solid or vicious - a Cavity Filler Ball Valve works efficiently in all conditions.

Like the name suggests, this ball valve has a cavity between the body, ball and the seat. This feature enables easy movement and therefore, improved efficiency.

Cavity Filler Ball Valves are easy to use and maintenance free.

Description | Features |

|---|---|

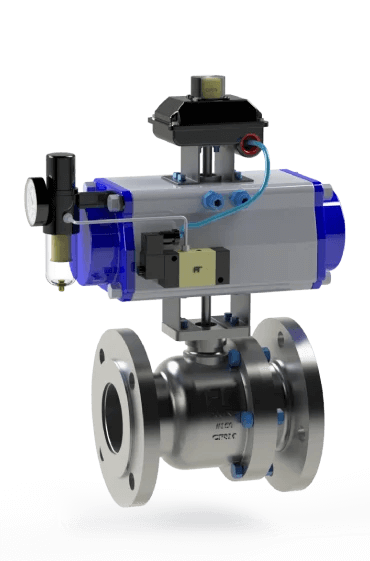

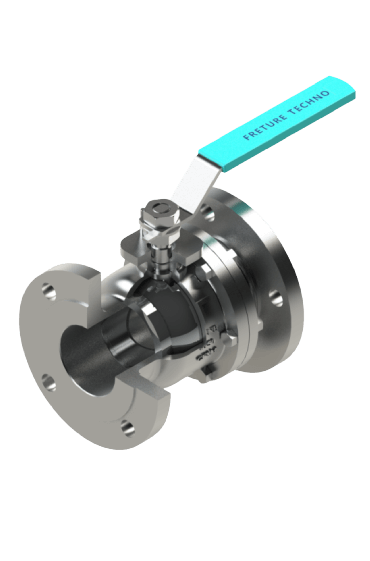

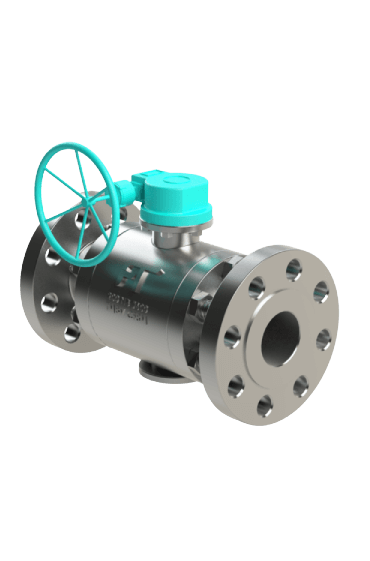

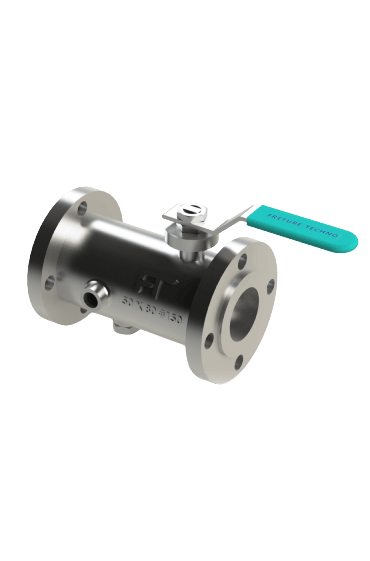

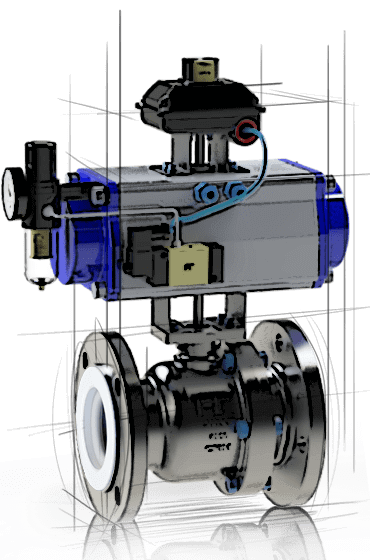

TYPE: Two Piece Zero Cavity Ball Valve End Connection : Flange (ASME B16.5) Size: 15 NB to 200 NB Class: 150# - 2500# Temperature Range: 35°C to 280°C Body Materials: Stainless Steel / Carbon Steel / Alloys Design Standard: API 6D rev 23; ISO 17292 rev 2004 Operation: Manual & Actuated (Rack & Pinion / Scotch Yoke / Electric) Gear Operated Face to Face Dimension: ASME B16.10 Rev 2009 Fire safe design: API-607 Rev 2010 Testing: API 598 Rev 2009 Sour Service: NACE MOR 0175 Rev 2009 Documents: BS/EN 10204-3.1 REV 2004 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Cavity Filler Ball Valve?

- How does it work?

It works by using a filled ball and seat that eliminates internal voids, ensuring a tight seal and preventing fluid from being trapped within the valve body.

- What are the main applications?

Main applications include food and beverage processing, pharmaceuticals, cosmetics, and other industries requiring high levels of cleanliness and hygiene.

- What are the benefits of using one?

Benefits include preventing contamination, ensuring a cleaner flow path, reducing maintenance needs, and enhancing process safety by eliminating fluid retention areas.

- What materials are used in their construction?

These valves are typically constructed from stainless steel or other corrosion-resistant materials, with cavity fillers made from PTFE or other suitable polymers.

- How do I choose the right one for my application?

Choose based on your specific fluid type, pressure, temperature requirements, and compatibility with sanitary standards relevant to your industry.

- Can they be repaired?

Yes, Cavity Filler Ball Valves can be repaired by replacing the cavity fillers, seals, and other components as needed.

- What maintenance is required?

Regular maintenance includes periodic inspection, cleaning, and replacement of worn cavity fillers and seals to ensure optimal performance and hygiene.

- Are they available in different designs?

Yes, they are available in various designs, including different sizes, end connections, and actuation methods to meet diverse application needs.

- Why is Freture the best place to buy from?

Freture offers high-quality Cavity Filler Ball Valves, backed by expert engineering, extensive industry experience, and a commitment to customer satisfaction. Our products are reliable, competitively priced, and tailored to meet the specific needs of your applications.

Industries where Cavity Filler Ball Valve is Used

Food and Beverage

Pharmacuticals

Chemical Processing

Water Treatment Industry

Petrochemical Industry

Application of Cavity Filler Ball Valve

- Sanitary Fluid Handling: Ensures contamination-free transport of liquids in food and beverage processing.

- Pharmaceutical Manufacturing: Maintains high purity levels by preventing fluid entrapment and contamination.

- Cosmetics Production: Provides a clean flow path for handling viscous and sensitive cosmetic ingredients.

- Chemical Processing: Prevents build-up of reactive chemicals in the valve body, enhancing safety and efficiency.

- Biotechnology: Ensures sterile conditions by eliminating cavities that could harbor contaminants.