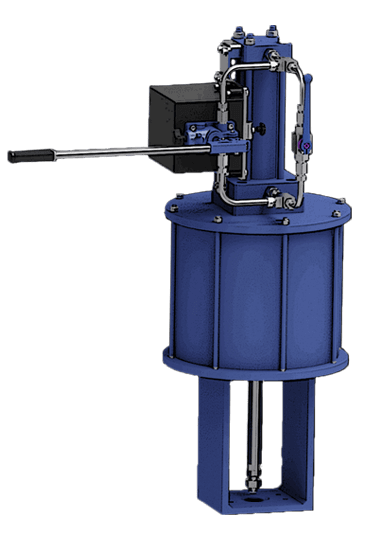

It is a mechanical device used to convert rotary motion into linear motion. It consists of a yoke attached to a rotating shaft, which moves back and forth in a scotch yoke track, enabling precise linear movement.

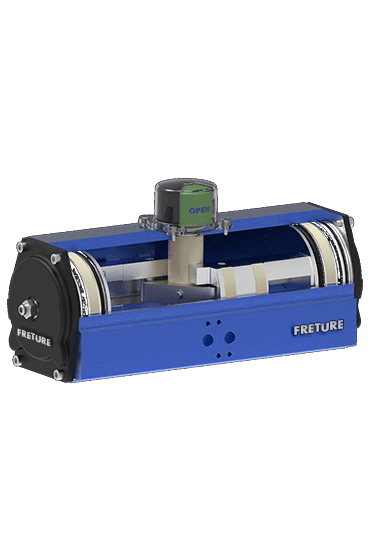

Scotch & Yoke Actuator

Delivers Precise Control In Demanding Applications.

We are a leading Pneumatic Scotch & Yoke Actuator manufacturer in Mumbai, India. They converts linear motion to Rotary Motion using a yoke mechanism. It provides high torque output and is commonly used in valve automation.

They are robust and versatile devices used for converting rotary motion into linear motion. The mechanism consists of a yoke attached to a rotating shaft, which moves back and forth in a scotch yoke track. This motion enables precise and reliable operation, making them ideal for applications requiring heavy-duty and high-performance linear motion control.

They are engineered with precision and crafted from premium materials to ensure durability and longevity. They are designed to operate smoothly and efficiently even in the most demanding environments.

The main applications of Pneumatic Scotch & Yoke Actuators span across industries such as oil and gas, chemical processing, water and wastewater treatment, power generation, and marine. They are utilized for valve automation, pipeline operation, control of process equipment, and various other critical tasks requiring precise linear motion control.

The benefits of choosing our thise actuators include their robust construction, reliable performance, high efficiency, and ease of maintenance. Our actuators are available in different sizes and configurations to suit the specific requirements of our customers.

When you choose us, you benefit from not only top-quality products but also exceptional customer service and technical support. We are committed to delivering reliable solutions that enhance the efficiency and productivity of your operations.

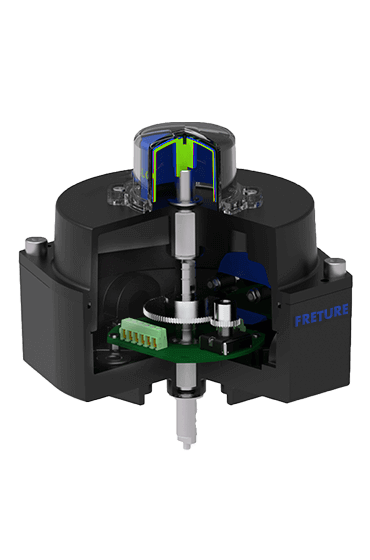

Description | Features |

|---|---|

TYPE: Pneumatic Scotch & Yoke Actuator. Torque: 20 Nm to 5,000,000 Speed: Upto 157 rad/s Rotation: 0° to 92° (Bidirectional) Air Supply Ports : VDI/VDE3845 NAMUR, EN ISO228 G1/8”, G1/4”, G1/2” Port Size : 1/8 inch to 2 inches (NPT or BSP) Pressure: - 1 bar to 12 bar (14.5 psi to 174 psi) Temperature : Extended Temperature - 60°C to 200°C (-76°F to 392°F) Material: Aluminium, stainless steel, cast iron, carbon steel, etc. Valve Interface: ATEX 2014/34/EU, ISO 5211, DIN 3337,VDE/VDI 3845 (NAMUR) Mounting Options.: flange, foot-mounted, shaft-mounted, etc. Noise Level : 50 dB to 65 dB Cycle Time: 0.1 seconds to 10 seconds Coating Options: PTFE coating,Hard Anodised, Nickel plated Springs:Cartridge: cartridge type,Shot peened. Endurance Testing : 500,000 cycles(EN 15714-3) Compliance : ISO 5211, CE, ATEX, ISO,EN etc. |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Pneumatic Scotch & Yoke Actuator?

- How does it work?

They work by utilizing the rotational motion of the shaft to drive the linear movement of the yoke along the scotch yoke track. This mechanism provides smooth and controlled linear motion, making it suitable for various industrial applications.

- What are the benefits of using one?

The benefits of using this Actuators include high torque output, precise and controlled angular movement, rapid and efficient operation, reliability, durability, and suitability for heavy-duty applications.

- What materials are used in their construction?

They are typically constructed from durable materials such as stainless steel, aluminum, and high-strength alloys, ensuring robustness and longevity even in harsh operating conditions.

- How do I choose the right one for my application?

Choosing the right Scotch & Yoke Actuator involves considering factors such as torque requirements, stroke length, operating speed, environmental conditions, and compatibility with the application's control system. Consulting with a knowledgeable supplier can help in selecting the most suitable actuator for your specific needs.

- Can they be repaired?

Yes, It can often be repaired. Maintenance and repair may involve replacing worn components, lubricating moving parts, and ensuring proper alignment. However, the extent of repairability depends on the design and the extent of damage.

- What maintenance is required?

Maintenance of this Actuators typically includes regular inspections, lubrication of gears and bearings, checking for wear and tear, and ensuring proper alignment. Following a preventive maintenance schedule can help prolong the actuator's lifespan and maintain optimal performance.

- Are they available in different designs?

Yes, they are available in various designs to suit different application requirements. These designs may include single-acting, double-acting, pneumatic, hydraulic, and electric actuators, each offering specific features and capabilities.

- Why is Freture the best place to buy from?

Freture is the best place to buy Scotch & Yoke Actuators due to its extensive range of high-quality products, expert technical support, competitive pricing, and commitment to customer satisfaction. Freture's actuators are designed to meet the highest industry standards, ensuring reliable performance, durability, and compatibility with diverse industrial applications.

Industries where Pneumatic Scotch & Yoke Actuators is Used

Oil and Gas

Chemical Processing

Water and Wastewater Treatment

Power Generation

Marine Industry

Applications

Valve Automation: They are widely used for automating valves in various industries, enabling precise control over fluid flow and pressure regulation.

Pipeline Operation: They are employed to control the opening and closing of valves along pipelines, ensuring efficient and reliable flow management.

Process Equipment Control: They play a vital role in controlling the operation of process equipment such as dampers and gates, facilitating optimal performance in industrial processes.

Emergency Shutdown Systems: These actuators are integral components of emergency shutdown systems, swiftly closing critical valves in hazardous situations to prevent accidents and ensure safety.

Heavy-Duty Applications: Due to their robust design and high torque capabilities, They are ideal for heavy-duty applications where reliable and precise linear motion control is required.