It is a mechanical device that converts rotational motion into linear motion. It is commonly used to automate the movement of various components in industrial machinery and equipment.

Linear Valve Actuator

Powering Precision: Advanced Systems for Seamless Motion

Freture Techno, a prominent Industrial Linear Valve Actuator manufacturer in Mumbai, India It converts rotational motion into linear motion, commonly automating industrial machinery movement. We are specializes in delivering high-quality Linear Valve actuators designed to meet the diverse needs of various industries. They are engineered with precision and crafted from premium materials to ensure durability, reliability, and optimal performance in demanding environments.

Featuring robust construction and advanced technology, these actuators offer smooth and precise linear motion control for a wide range of applications. With a focus on innovation and quality, we provide industrial Linear Actuators that are capable of handling tasks of different scales with high efficiency and accuracy.

Features and Types : They stand out due to their robust construction, precise positioning, and high force output. We offer a range of Linear Valve Actuators tailored to different needs:

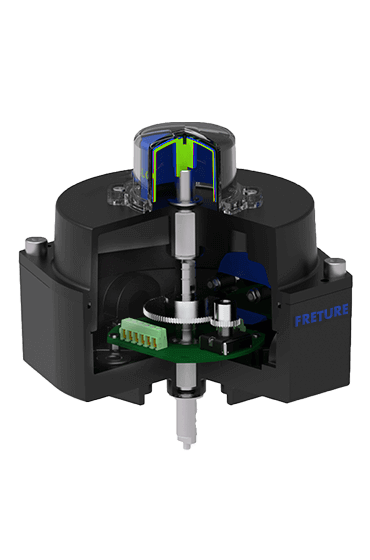

- Electric : Perfect for applications requiring accurate and programmable motion control.

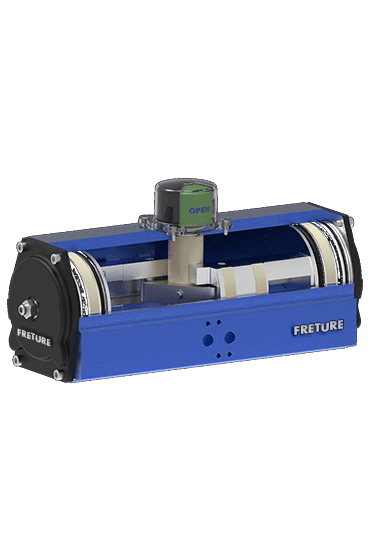

- Pneumatic : are ideal for rapid, reliable actuation in industrial environments.

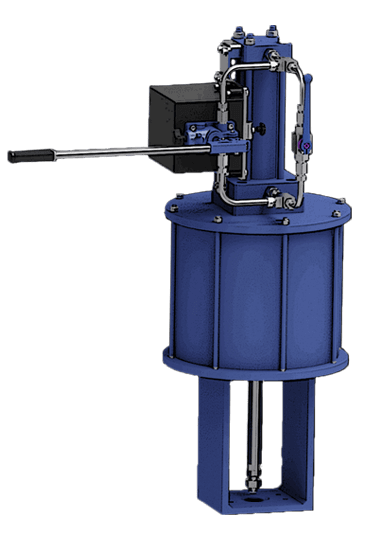

- Hydraulic : Suitable for heavy-duty applications where high force and durability are essential.

Whether it's for valve automation, conveyor systems, robotics, or industrial machinery, they are designed to meet the stringent requirements of modern industrial applications. With our dedication to excellence and customer satisfaction, Freture Techno is your reliable partner for high-quality Pneumatic, Motor, Electric Linear Valve Actuator suppliers, ensuring unmatched performance and reliability.

Download Brochure

Description | Features |

|---|---|

TYPE : Double-acting, single-acting (spring return) Air Supply Ports : EN ISO228 G1/2”, G1”, G1.1/2” Port Size : 1/8 inch to 1 inch (NPT or BSP) Bore Size: 20 mm to 320 mm (0.79 inches to 7.87 inches) Rod Diameter : 6 mm to 80 mm (0.24 inches to 3.15 inches) Stroke Length: 2", 4", 6", 8", 12", 16", 20", 30 Pressure : 2 bar to 10 bar (29 psi to 145psi) Operating Temperature : - 60°C to 200°C (-76°F to 392°F) Material : Aluminum, stainless steel, composites Mounting Options : Clevis, trunnion, flange, Rod,etc. Valve Interface : Mounting Flange(ISO 5210) Seals : Nitrile, Viton, EPDM, etc. Manual Override : handwheel or gearbox Noise Level : 50 dB to 65 dB Endurance Testing : 500,000 cycles Testing Compliance : ISO, ANSI, CE,EN60529 for IP68 etc. |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Linear Actuator?

- How does it work?

Industrial Electric / Pneumatic Linear actuators operate by converting the rotary motion of a motor or other power source into linear motion. This is typically achieved through the use of screws, belts, or other mechanisms that translate the rotational movement into linear displacement.

- What are the main applications?

These Actuators find extensive applications in various industries, including valve automation, conveyor systems, robotics, medical equipment, aerospace, and automotive manufacturing. They are used for precise positioning, lifting, pushing, pulling, and other linear motion tasks.

- What are the benefits of using one?

The benefits of using a linear actuator include precise and controlled motion, high reliability, compact design, energy efficiency, versatility, and the ability to automate complex tasks, thereby improving efficiency and productivity.

- What materials are used in their construction?

They are typically constructed from materials such as stainless steel, aluminum, and high-strength plastics. The choice of material depends on factors such as durability, weight, and resistance to environmental factors.

- How do I choose the right one for my application?

Choosing the right linear actuator involves considering factors such as load capacity, stroke length, speed requirements, operating environment, and compatibility with the application's control system. Consulting with a knowledgeable supplier can help in selecting the most suitable actuator for your specific needs.

- Can they be repaired?

Yes, Linear Actuators can often be repaired. Maintenance and repair may involve replacing worn components, lubricating moving parts, and ensuring proper alignment. However, the extent of repairability depends on the design and the extent of damage.

- What maintenance is required?

Maintenance of linear actuators typically includes regular inspections, lubrication of moving parts, checking for wear and tear, and ensuring proper alignment. Following a preventive maintenance schedule can help prolong the actuator's lifespan and maintain optimal performance.

- Are they available in different designs?

Yes, linear actuators are available in various designs to suit different application requirements. These designs may include ball screw actuators, lead screw actuators, belt-driven actuators, and linear motor actuators, each offering specific features and capabilities.

- Why is Freture the best place to buy from?

Freture is the best place to buy linear actuators due to its extensive range of high-quality products, expert technical support, competitive pricing, and commitment to customer satisfaction. Freture's actuators are designed to meet the highest industry standards, ensuring reliable performance, durability, and compatibility with diverse industrial applications.

Industries where This Actuator is Used

Oil and Gas Industry

Chemical Processing Industry

Water Treatment Industry

Power Generation Industry

Pharmaceutical Industry

Applications

Valve Automation: They are used to automate the operation of industrial valves, enabling remote and precise control of fluid flow in pipelines.

Process Control: They facilitate the regulation of flow rates and pressure in industrial processes by precisely positioning valve openings.

Emergency Shutdown Systems: They are integral components of emergency shutdown systems, swiftly closing critical valves in hazardous situations to prevent accidents and ensure safety.

Flow Regulation: They play a crucial role in adjusting valve openings to regulate flow rates and maintain optimal process conditions in various industries.

Pressure Relief Systems: They are utilized in pressure relief systems to control the opening and closing of safety valves, ensuring the safe release of excess pressure in industrial environments.