A Local Control Station (LCS) is a device used to provide the flexibility of utilizing remote process control signals for equipment operation or operating the equipment directly at the desired location, whether at the equipment itself or nearby. It allows for the mounting of control elements on a mounting rail or in the front wall, with designated free installation areas allocated for subsequent installation of control and signaling devices, sealed using blanking plugs.

Local Control Station

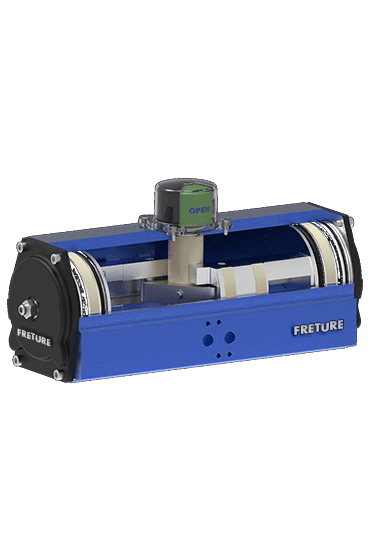

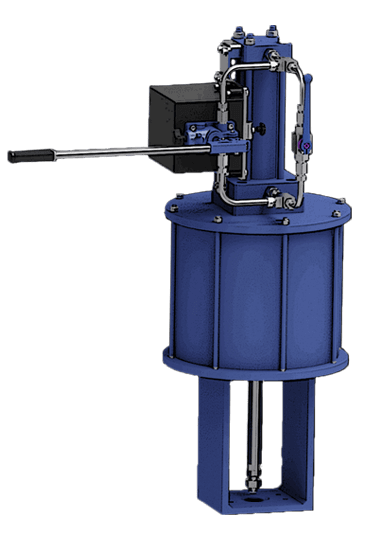

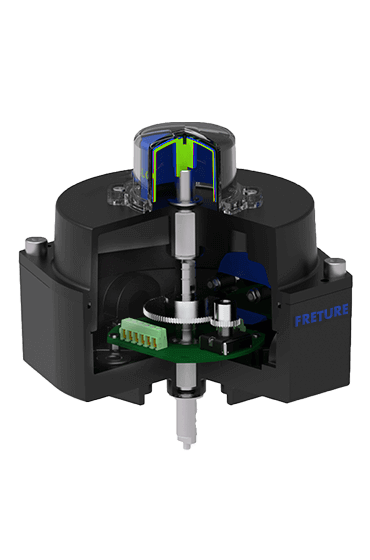

Freture Techno is a leading Local Control Station (LCS) manufacturer in Mumbai, India. LCS (Atex Local Push Button Station) provides the flexibility of utilizing remote process control signals for equipment operation or operating the equipment directly at the desired location, whether at the equipment itself or nearby. The control elements can be mounted on a mounting rail or in the front wall. Additionally, designated free installation areas can be allocated for the subsequent installation of our control and signaling devices, which are then sealed using blanking plugs. All explosion-protected Local Control Station are prewired on terminals.

Download Brochure

Description | Features |

|---|---|

Enclosure: ATEX / IECEx TERMINAL : 60 Body Materials: ALUMINIUM PRESSURE DIE CAST Temperature Range: -40°C to +80°C Weight: 2.7 Kg (6.0 lbs) Mounting Options: Wall or pole mounted Power supply: Actuator derived OR 24VDC /120VAC / 230VAC LED indications : POWER,READY, OPEN, CLOSE Environmental protection: IP68 /IP65 / IP67 available Certification : IP 66 IP 68 Standard / CE marking / Ex d, IIC, T6 / RoHs

| Robust Material : Durability and resilience in challenging industrial environments. Safety : Highest safety and protection in hazardous environments. Ergonomic Design : Durable and weather-resistant enclosure to ensure protection against harsh environmental Temperature Range : Ensuring consistent performance in extreme temperature conditions. Quick Halt : Emergency stop button for immediate halting. Remote Monitoring Capability : access and monitor the control station from a central location. Comprehensive Design: Equipped with audible alarms for immediate fault alerts, a clear and intuitive interface with easily identifiable controls and indicators. |

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Local Control Station (LCS)?

- How does it work?

The Local Control Station operates by providing a platform for mounting control elements either on a mounting rail or in the front wall. atex push button station facilitates the utilization of remote process control signals for equipment operation or direct operation of the equipment at the desired location.

- What are the main applications?

Local Control Station find primary applications in various industries such as oil and gas, chemical processing, water treatment, power generation, and manufacturing. They are used for controlling and monitoring equipment operation, ensuring efficient and reliable process control.

- What are the benefits of using one?

The benefits of using a Local Control Station include flexibility in equipment operation, ease of control and monitoring, efficient utilization of remote process control signals, convenient installation, and enhanced safety.

- What materials are used in their construction?

Local Control Station are typically constructed from durable materials such as stainless steel, aluminum, and high-strength plastics. These materials ensure reliability, durability, and resistance to harsh environmental conditions.

- How do I choose the right one for my application?

Choosing the right Local Control Station involves considering factors such as the specific requirements of the application, environmental conditions, the type of control elements needed, and compatibility with the existing control system. Our technical experts can assist in selecting the most suitable option for your specific application needs.

- Can they be repaired?

Yes, Local Control Station can often be repaired. Maintenance and repair may involve replacing faulty components, adjusting settings, and ensuring proper calibration to restore functionality.

- What maintenance is required?

Regular maintenance of Local Control Station typically includes inspection, cleaning, and testing of components, as well as ensuring proper sealing and functionality of control elements. Following a preventive maintenance schedule can help prolong the lifespan and ensure optimal performance of the device.

- Are they available in different designs?

Yes, Local Control Station are available in various designs to accommodate different installation requirements and application needs. These designs may include different enclosure types, mounting options, and configurations to suit specific industry standards and regulations.

- Why is Freture the best place to buy from?

Freture is the best place to buy Local Control Station due to our commitment to providing high-quality products, expert technical support, competitive pricing, and exceptional customer service. Our Local Control Station are designed and manufactured to the highest industry standards, ensuring reliability, durability, and performance in diverse industrial applications.

Industries where Local Control Station is Used

Oil and Gas Industry

Chemical Processing Industry

Water Treatment Industry

Power Generation Industry

Pharmaceutical Industry

Applications of Local Control Station (Atex Local Push Button Station)

Valve Monitoring and Control: They are used to monitor and control industrial valves, allowing for precise operation and adjustment of valve positions.

Process Automation: They facilitate process automation by providing a centralized point for controlling various valves in industrial systems, enhancing operational efficiency.

Emergency Shutdown Systems: They are integrated into emergency shutdown systems to quickly and effectively close critical valves in hazardous situations, ensuring safety and preventing accidents.

Remote Operation: They enable remote operation of valves, allowing operators to control valve positions from a convenient location, improving accessibility and ease of use.

Fault Detection and Diagnostics: They provide real-time feedback on valve status, enabling operators to detect faults and diagnose issues promptly, minimizing downtime and optimizing maintenance schedules.