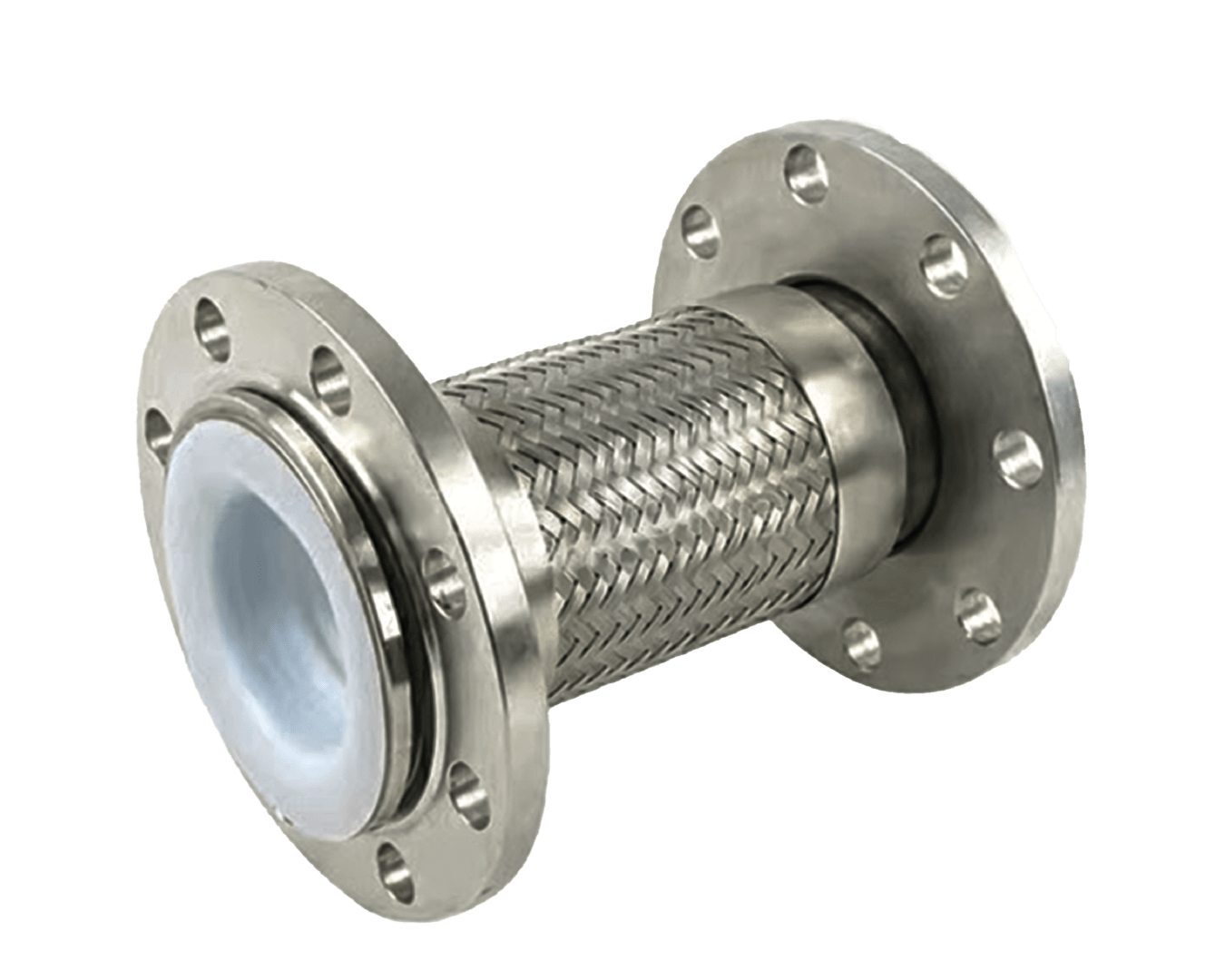

PTFE Flexible Hoses

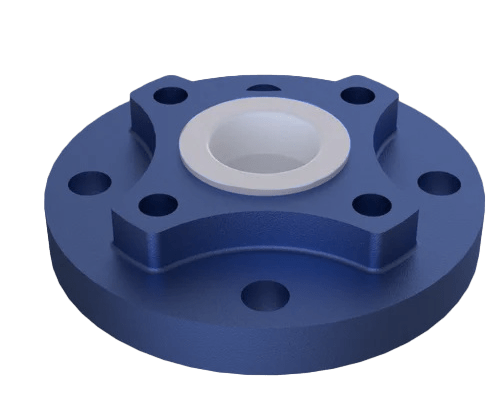

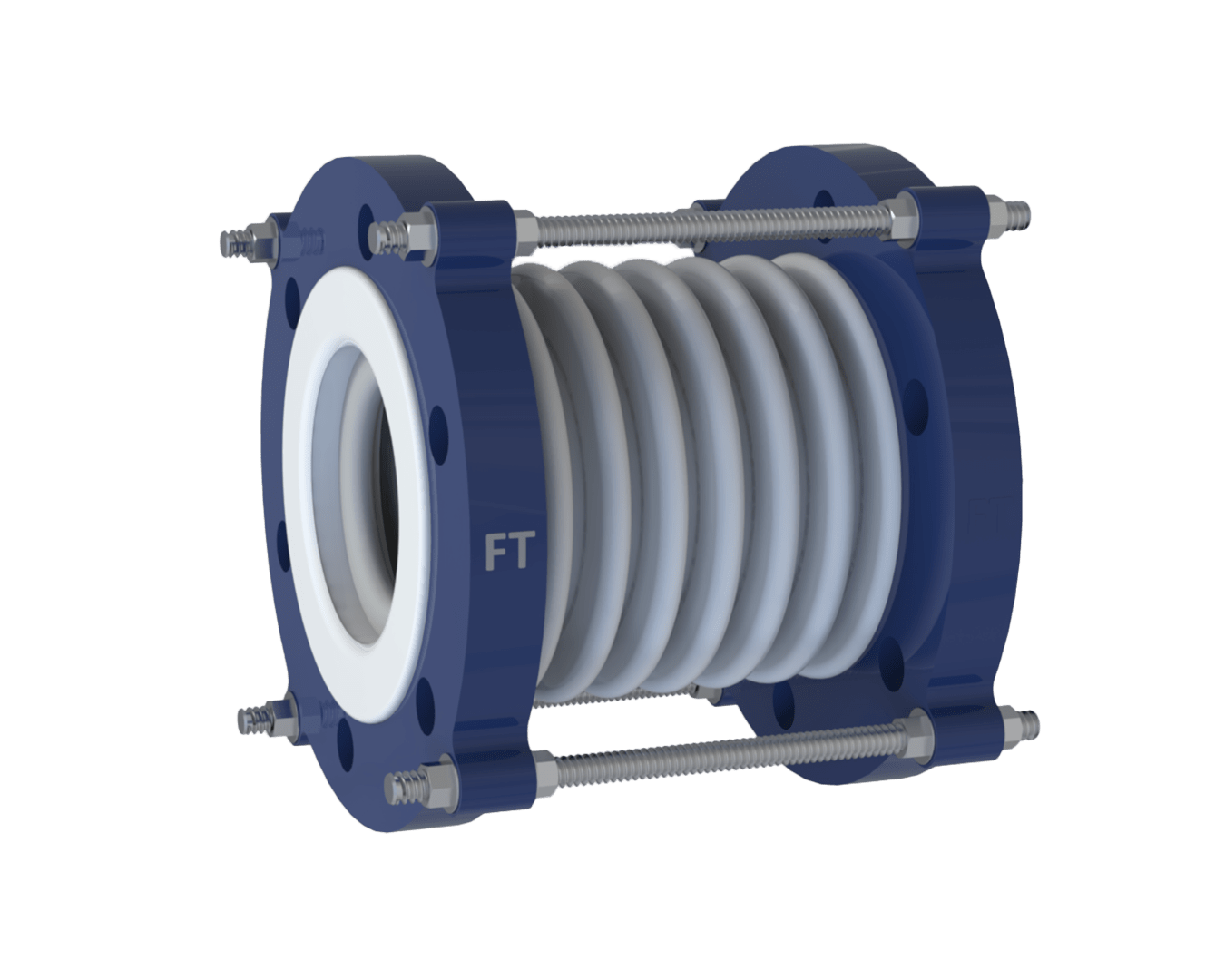

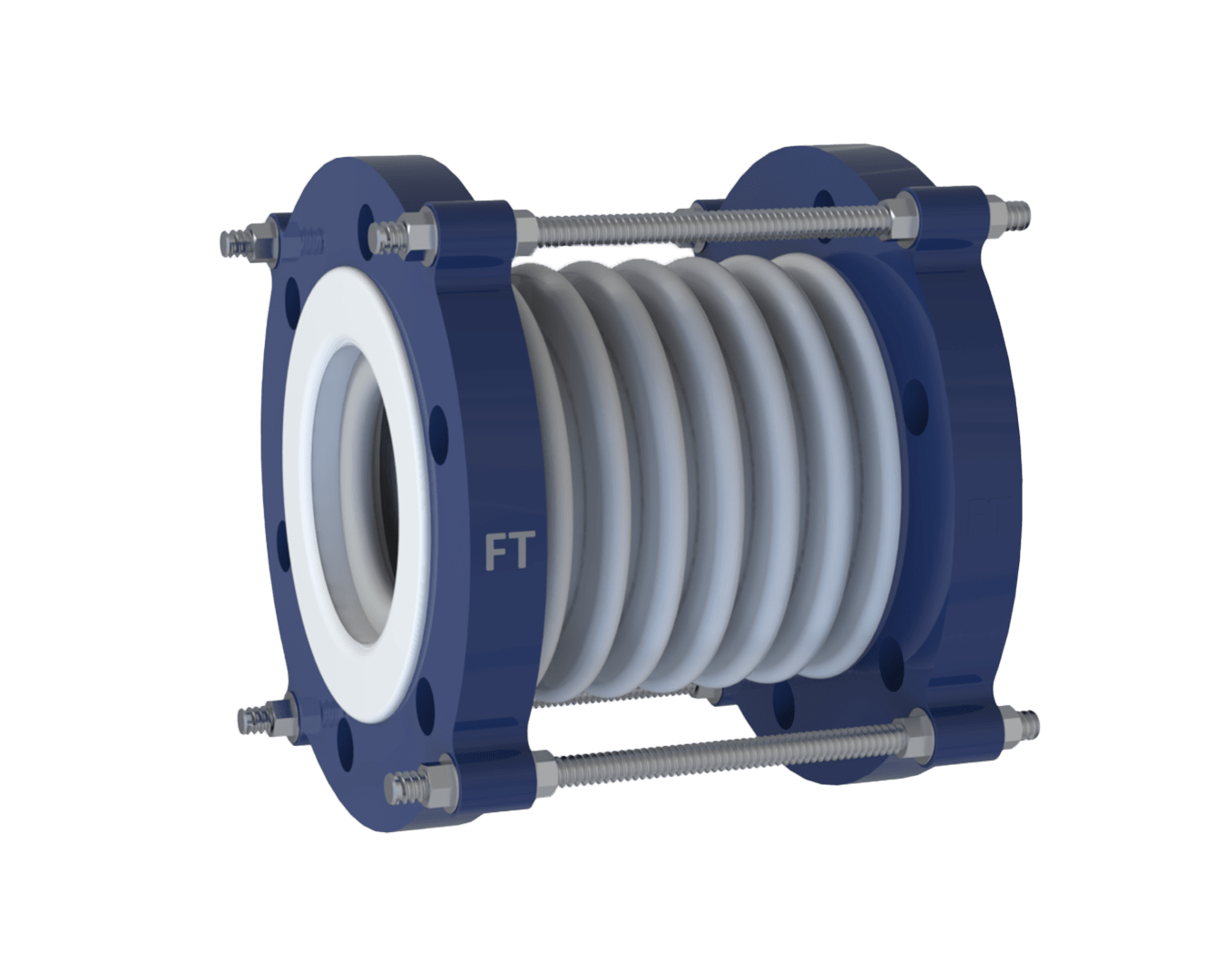

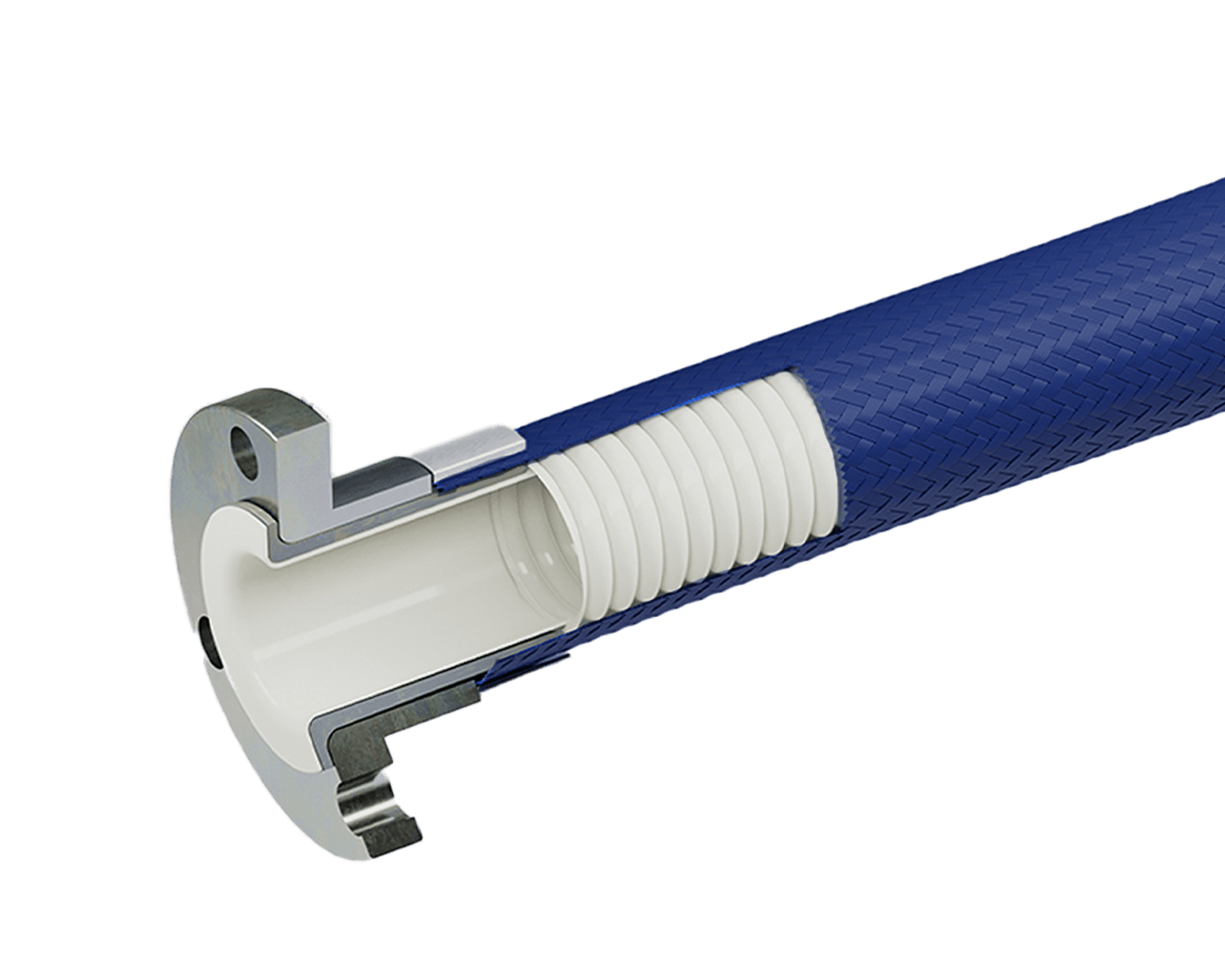

We are leading Teflon Hoses Manufacturer, Supplier in Mumbai, India. A PTFE Lined Hose is a flexible engineering solution designed for safe transfer of aggressive chemicals, high-purity fluids, and high-temperature substances across industries. The polytetrafluoroethylene (PTFE) inner lining ensures exceptional chemical resistance, low friction, and teTemperature resilience (-70°C to +260°C), making it ideal for demanding applications. The smooth PTFE surface guarantees clean fluid flow, while the flexible outer layer—reinforced with braided stainless steel or synthetic materials—provides strength and durability. This flexibility allows the convoluted PTFE Flexible hoses to absorb vibrations, accommodate thermal expansion, and adjust to misalignments, ensuring safe operation in dynamic environments.

Advantages of Using Teflon Lined Flexible Hoses in Industries

The PTFE lining resists corrosion from acids, alkalis, solvents, and high-temperature liquids. Available in smooth bore or convoluted designs, the flexible lined hose caters to diverse needs: smooth bore variants optimize flow efficiency, while convoluted types enhance flexibility for tight bends. Industries like pharmaceuticals, oil and gas, chemical processing, and food and beverage rely on its purity retention and system longevity.

Applications of PTFE Lined Flexible Hoses

- Pharmaceutical Industry – For transferring pure water, solvents, and sensitive fluids without contamination.

- Chemical Processing – Safely handles corrosive and aggressive chemicals.

- Oil and Gas Sector – Withstands extreme temperature and pressure variations.

- Food and Beverage Industry – Manufactured with FDA-approved PTFE powders, ensuring hygiene and purity.

- Automotive and Aerospace – Reliable under high pressure, thermal cycling, and exposure to harsh fluids.

Why Choose PTFE Lined Flexible Hoses?

- High tensile strength and durability.

- Resistance to peroxides and oxidation.

- Compliance with FDA standards for safe food handling.

- Enhanced system longevity and operational efficiency.

Flexible PTFE Lined Hose Supplier in India

As a leading PTFE-lined flexible Hose manufacturer in Mumbai, India, we provide high-quality hoses engineered for durability, purity, and safety across industries. Our hoses are available in multiple configurations to meet varied industrial requirements, ensuring superior performance and long service life.

Manufactured with FDA-approved PTFE powders, this lined flexible PTFE Lined Flexible Hoses is safe for food applications. Its high tensile strength, resistance to peroxides, and ability to withstand thermal cycling and pressure make it a top choice for automotive, aerospace, and industrial sectors. Integrating this flexible hose enhances durability, safety, and operational efficiency while reducing maintenance costs.

Specifications | Features |

|---|---|

Type: Teflon Flexible Hose Lining Material: PTFE, FEP, PVDF Reinforcement: Stainless Steel Braided / Synthetic Fiber Reinforced Size Range: ½” to 12” Pressure Rating: Up to 150 psi (Class 150) Temperature Range: -40°C to 200°C End Connections: Flanged, Threaded, Quick Connect Couplings Construction: Multi-layer (Lining + Reinforcement + Outer Cover) Standards: Complies with ISO/ASTM standards Cycle Life: High cycle life design Documentation: Material Test Certificate (MTC), Pressure Test Report, etc. |

|

Industries where PTFE Hose is Used

Pharmaceutical Industry

Oil and Gas Industry

Chemical Industry

Power Generation Industry

Petrochemical Industry

Application

- Fluid Transfer: Ensuring contamination-free movement of high-purity water or saline solutions in drug formulation processes.

- Clean-In-Place (CIP) Systems: Delivering cleaning agents to sanitize equipment without disassembly, maintaining hygiene standards.

- Emissions Monitoring Systems: Conveying sample gases for analysis to ensure environmental compliance.

- Chemical Injection Lines: Delivering corrosion inhibitors and other chemicals into pipelines to maintain flow efficiency.

- Gas Transfer Lines: Safely conveying natural gas or other hydrocarbons under high pressure.