Teflon lined columns offer excellent chemical resistance to a wide range of aggressive chemicals, including acids, alkalis, and solvents. lined columns provide superior protection against highly corrosive acids and solvents, offering both chemical resistance and ease of cleaning for highly reactive materials.

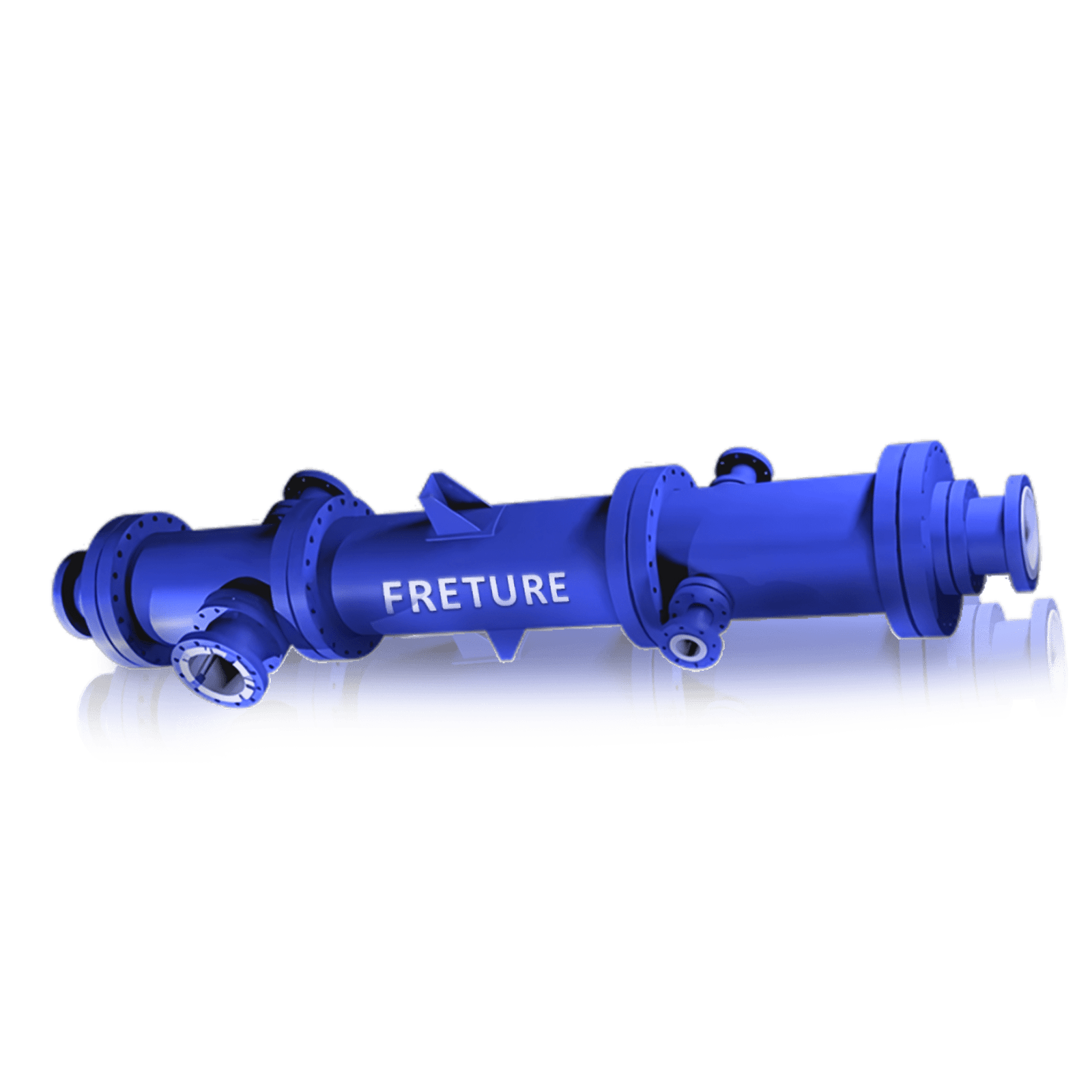

PTFE Lined Column

PTFE lined columns operate by utilizing the principles of mass transfer to separate different components within a mixture, such as liquid and vapor. These columns work by allowing the materials to flow countercurrently—liquid flows downward, while vapor rises through the column. As the vapor and liquid interact, components with different volatilities are separated, with the lighter components typically rising and the heavier ones descending. This countercurrent flow maximizes the surface area for mass transfer, ensuring effective separation in processes like distillation, absorption, and extraction.

Constructed with durable materials such as carbon steel, stainless steel, or ductile iron, these columns are lined with either high-performance PTFE (Teflon). The distillation column is equipped with essential internal components, including liquid spray tubes, packing support plates, structural packing, and pall rings, to enhance separation efficiency. Additional features like thermowells, temperature transmitters, and sight ensure precise monitoring and control of the process.

PTFE lined columns are available in a wide range of size, from 150 mm to 2130 mm in diameter, with lengths up to 6 meters. They operate efficiently within a temperature range of -29°C to +210°C and can withstand pressures up to 10 bars, making them suitable for demanding applications. Designed to meet international standards like ASME Section VIII Division 1 and EN 13445, these columns ensure high operational reliability and long-term performance. With a variety of custom options and rigorous quality checks, both Teflon and glass-lined columns are ideal for industries requiring durable, corrosion-resistant solutions for critical separation and purification processes.

Specifications | Features |

|---|---|

Type: Lined Column Standard: EN 13445, EN 14483, ASME Section VIII Division 1 End Connection: ANSI B 16.10 / DIN 1092-1 Diameter: 6” (150 mm) to 84” (2130 mm) Length: Up to 236” (6000 mm) Capacity: 50L to 20,000L Temperature: -29°C to +210°C Lined: PTFE / PVDF / GLASS / FEP / PFA Line Thickness: 3 mm - 6 mm Shell Material: Ductile Iron, Cast Steel, Stainless Steel 304/316 Pressure: Up to 10 bars Option: Vacuum resistance system to withstand partial vacuum |

|

Related Products

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- How do lined columns differ in terms of material properties?

- Can these columns be customized to suit my specific application?

Yes,Teflon lined columns are customizable. They can be tailored in terms of size, lining thickness (3mm or 6mm), and internal components, such as packing support plates, spray tubes, thermowells, and temperature transmitters, to meet the specific needs of your process.

- What are the advantages of using PTFE lining over other types of linings?

PTFE lining offers superior chemical resistance, a wide operating temperature range, and excellent non-stick properties, making it ideal for handling aggressive chemicals without degradation. It also provides long-term durability and minimal maintenance.

- How long does the PTFE or glass lining last?

The lifespan of the lining depends on factors such as the type of chemicals being processed, operating conditions, and maintenance. Under optimal conditions, both PTFE and glass linings are designed to last for many years, with minimal wear and corrosion.

- What are the maintenance requirements for Teflon and glass-lined columns?

Maintenance typically involves regular inspections for signs of wear, cleaning to prevent clogging, and checking the integrity of the lining. Ensuring that the operating parameters (temperature, pressure, and flow rate) are within the recommended limits will also help extend the life of the column.

- How do Teflon and glass-lined columns withstand the extreme conditions of the oil & gas industry?

Teflon and glass-lined columns are specifically designed to handle the harsh and corrosive environments typical of the oil & gas industry. The PTFE lining offers exceptional resistance to a wide range of aggressive chemicals, including acids, alkalis, and hydrocarbons commonly found in oil & gas refining processes. Glass-lined columns provide superior protection against highly corrosive substances, including sulfuric acid and other acidic byproducts. Both linings offer durability in the face of high pressures, temperatures, and reactive substances.

Industries where Lined Column is Used

Chemical Industry

Pharmaceutical Industry

Petrochemical Industry

Food & Beverage Industry

Water Treatment System

Applications

- Extraction of Bioactive Substances: Utilized in the extraction of bioactive substances from plants, natural products, or fermentation processes.

- Crude Oil Distillation: Teflon and glass-lined columns are essential for distilling crude oil into its various fractions, including gasoline, diesel, and kerosene.

- Recovery: Used in the recovery and purification of acids, including sulfuric acid, hydrochloric acid, and nitric acid, to prevent corrosion and improve efficiency.

- Gasoline and Diesel Purification: Used in the purification of gasoline and diesel to remove impurities and improve quality.

- Gas Scrubbing: Teflon and glass-lined columns are utilized for scrubbing gases in industries, removing unwanted pollutants from gas streams.

- Sugar Refining: Glass-lined and PTFE-lined columns are used in the refining of sugar, separating unwanted impurities and ensuring a high-purity product.