A bronze type safety valve is a pressure relief valve made from bronze, designed to release excess pressure from systems to prevent damage or failure.

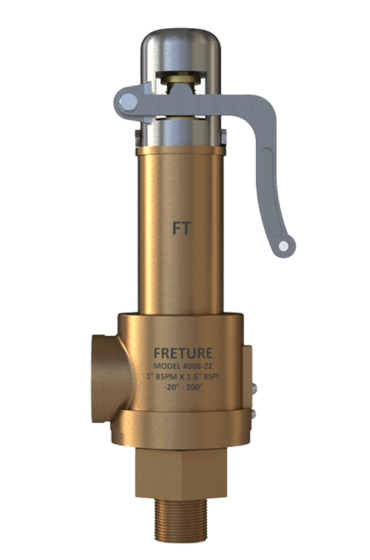

Safety Valve Series #033

We are leading Bronze Safety Relief Valve Manufacturer in Mumbai, India .Bronze Safety Relief Valve with ASME Section VIII Division 1, ASME B16.34, API 526, API 527, and IS 12992 standards, ensuring reliability and quality. sizes ranging from 15NB - 200NB versatile thread end connections (BSP, BSPT, NPT), set pressure range of 1 BAR to 35 BAR and a temperature range of -20°C to 200°C. Notable features include direct spring operation, full lift, full nozzle, single trim, fixed blow-down ring, metal/Viton rubber seat, and a maintenance-free design. Designed for air, gas, and water applications.

Description | Features |

|---|---|

TYPE: Bronze Safety Valve End Connection: Thread End Connection (BSP, BSPT, NPT, etc.) Size: 3/4” x 1” TO 1” x 1.5” Pressure Rage: 0.5 to 40 Barg Temperature Range: -20°C to 200°C Material: Full Gun Metal Bronze & Brass Construction Design Standard: API 520, API 527, EN ISO 4126 Part.1, ASME Section VIII Div. I, etc. Seal: Metal to Metal Seat lapped for Optical Seat Flatness Operation: Direct Spring Operated & Pop Type action Certification: CE Certified under Category IV Module H (2014/68/EU) |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a bronze type safety valve?

- How do bronze type safety valves work?

They operate by opening automatically when the pressure inside a system exceeds the preset limit, allowing excess fluid or gas to escape until the pressure returns to safe levels.

- What are the advantages of using it?

Advantages include reliability, long service life, low maintenance requirements, and suitability for applications involving steam and corrosive fluids.

- Where they are commonly used?

They are commonly used in industries such as marine, oil and gas, chemical processing, and steam applications where reliable pressure relief is essential.

- What are different types they are available in?

Types include direct spring-loaded valves, pilot-operated valves, and balanced bellows safety valves, each tailored for specific pressure relief needs.

- How can I determine the correct size of valve for my application?

Type selection depends on factors such as maximum operating pressure, flow rate, and type of fluid or gas being handled, often guided by industry standards and regulations.

- Can it be used in high-temperature applications?

Yes, bronze type safety valves are suitable for high-temperature applications due to bronze's excellent thermal resistance.

- Which design standards are followed?

Bronze type safety valves adhere to design standards such as ASME (American Society of Mechanical Engineers) and API (American Petroleum Institute) to ensure safety, reliability, and performance in various applications.

- What Maintenance Is Required?

Maintenance typically involves regular inspection, testing, and cleaning to ensure proper functioning and compliance with safety standards.

- Why to choose Freture to buy it from?

Freture has years of experience in valve manufacturing. We understand the importance of safety in every industry, and as a leading safety valve manufacturer, we provide the best solutions to your flow control and safety problems with cutting-edge technology and a team of experts. Freture is always committed to providing exceptional solutions through our service.

Industries where Bronze Safety Valve is used

Oil and Gas Industry

Boiler and Reactors

Pharmaceutical Industry

Chemical Processing

HVAC Systems

Applications of Bronze Safety Valve

- Pressure Vessels: Safeguarding against excessive pressure buildup.

- Compressed Air Systems: Protecting compressors and storage tanks.

- Boilers: Preventing overpressure in steam and hot water boilers.

- Pharmaceutical Equipment: Ensuring safe pressure in processing equipment.

- Food and Beverage Processing: Maintaining safety in pasteurization and carbonation processes.