An open bonnet safety valve is a type of pressure relief valve where the bonnet covering the valve mechanism is open and accessible.

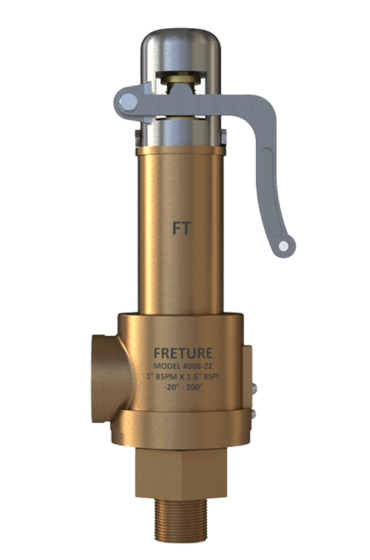

Flange End Pressure Relief Safety Valve

FRETURE leading Pressure Relief Safety Valve manufacturer in Mumbai, India. Open & Closed Bonnet Safety Valve meets rigorous standards including ASME Section VI, API 520, API 526, API 527, EN ISO 4126, and IS 12992, ensuring top-notch performance. Available in sizes ranging from 15NB - 200NB with Flange End (ANSI B 16.5 R.F.) connections, it operates within a set pressure range of 1 BARG to 414 BARG and a temperature range of -196°C to 538°C. Featuring direct spring operation, full lift, full nozzle, single trim, adjustable blow-down ring, and superior seat tightness, it's an ideal choice for controlling ing flow of air, gas, steam, and different liquid.

Description | Features |

|---|---|

TYPE: Open & Closed Bonnet Safety Valve End Connection: Flange End Connection (ANSI B 16.5 R.F.) Size: 15NB - 200NB Pressure Range: 0.5 to 414 Barg Temperature Range: -196°C to 400°C Body Materials: Stainless Steel, Carbon Steel, Brass, etc. Design Standard: API 520, API 526, API 527, API 521, EN ISO 4126 Part 1, ASME Section VIII Div. I, etc. Seat Options: Metal Seat or Soft Seat Operation: Direct Spring Operated Certification: CE Certified under Category IV Module H (2014/68/EU) |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is an open bonnet safety valve?

- How does it work?

It works by lifting the valve disk to release excess pressure when it exceeds a safe threshold, allowing fluid or gas to escape and prevent equipment damage.

- Where these valves commonly used?

They are commonly used in industries such as chemical processing, refining, and oil and gas, where frequent inspection and maintenance are necessary.

- What are the advantages of it over conventional ones?

They are used in various pressure systems including steam boilers, pressure vessels, and pipelines.

- How to choose right configuration for my application?

To Choose the valve by conside system pressure, size, application requirements, material compatibility, industry standards, and ease of maintenance to ensure optimal performance and safety.

You can also take help of our experts for free consultation.

- How often they should be inspected?

Commonly,They should be inspected regularly according to industry standards, typically ranging from monthly to annually, depending on the application.

- Can these valves be retrofitted into existing systems?

Yes, they can often be retrofitted depending on the compatibility and requirements of the system.

- Can these valves be repaired on-site?

Yes, open bonnet safety valves design allows for easier on-site repairs and adjustments compared to conventional safety valves.

- What are the maintenance requirements?

Maintenance typically involves cleaning, lubrication, checking for wear and tear, and verifying calibration.

- Why to choose freture?

Freture has years of experience in valve manufacturing. We understand the importance of safety in every industry, and as a leading safety valve manufacturer, we provide the best solutions to your flow control and safety problems with cutting-edge technology and a team of experts. Freture is always committed to providing exceptional solutions through our service.

Industries where a Pressure Relief Safety Valve is Used

Chemical Processing

Power Generation

Boiler And Reactor

Oil and Gas Industry

Petrochemical Industry

Applications of Pressure Relief Safety Valve

- Steam Boilers: To release excess steam pressure and prevent explosions.

- Pressure Vessels: To maintain safe pressure levels in storage tanks and reactors.

- Compressors: To relieve excess pressure and prevent damage to machinery.

- Chemical Reactors: To control pressure during chemical reactions and prevent hazardous releases.

- Cryogenic Systems: To safely release pressure in low-temperature applications.