A pop-type safety valve is a pressure relief valve that operates by using a spring-loaded disk or piston to relieve excess pressure in a system.

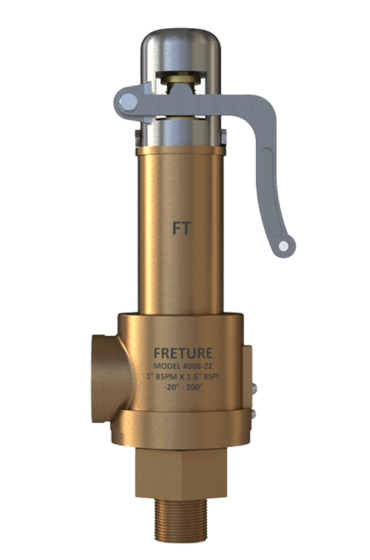

Pop Type Safety Valve

FRETURE is High Pressure Pop Type Safety Valve Manufacturers in Mumbai, India, Ensures compliance with industry standards. including ASME SEC VI 1, API 526, API 527, ASME 16.34, and IS 12992. Available in sizes ranging from 1/2" to 3" with versatile thread-end connections (BSP, BSPT, NPT), it operates within a set pressure range of 1 BAR to 21 Bar and a temperature range of -20°C to 250°C. Notable features include direct spring opera- on, full lid, full nozzle, single trim, adjustable blow-down ring, superior seat quality, metal-to-metal seat, and high capacity. Ideal for applications in air, gas, and steam systems.

High Pressure Pop Type Safety Valves are essential components in industrial systems, designed to prevent overpressure conditions that could lead to equipment failure or operational hazards. These valves provide an automatic pressure relief mechanism, ensuring system safety and efficiency. Their pop type action allows for instant opening and resealing, maintaining stable pressure levels while preventing unnecessary fluid loss.

Industries such as oil and gas, power generation, chemical processing, and pharmaceuticals rely on these valves to maintain controlled pressure environments. With their ability to handle high-pressure conditions, they play a vital role in steam systems, gas handling, and compressed air networks.

Key Features

- Automatic Overpressure Protection – The valve opens instantly when pressure exceeds the set limit, preventing damage.

- Rapid Response Mechanism – Ensures quick pressure release and resealing for continuous system stability.

- Minimal Leakage – The advanced sealing system reduces fluid loss and enhances efficiency.

- Durable Construction – Made from high-quality materials, these valves withstand extreme conditions and prolonged use.

- Low Maintenance – The simple yet robust design ensures easy installation and long service life.

- Industry Compliance – Meets global safety standards, ensuring reliability in industrial applications.

Benefits

High Pressure Pop Type Safety Valves offer multiple advantages that contribute to enhanced operational efficiency and safety. They provide immediate pressure relief, protecting equipment from damage and reducing downtime. Their leak-proof design prevents fluid wastage, making them cost-effective for industries dealing with high-value materials.

These valves also help industries comply with safety regulations and industry standards, ensuring a secure working environment. Their ability to handle high-capacity discharge makes them suitable for demanding applications in boiler systems, gas distribution, and industrial processing units.

Challenges and Considerations

Despite their numerous benefits, these valves require proper installation and calibration to function effectively. Incorrect pressure settings may lead to operational inefficiencies such as valve chattering or delayed response. Additionally, selecting the right material composition is crucial for applications involving corrosive substances to prevent premature wear.

Regular inspection and maintenance are recommended to ensure optimal performance and compliance with industry regulations.

Industrial Applications

These Valves are widely used in various industries where pressure regulation is critical:

- Oil & Gas Industry – Ensures safety in pipelines, refineries, and gas storage units.

- Power Generation – Protects boilers, turbines, and steam systems from excessive pressure.

- Chemical Processing – Prevents overpressure in high-temperature reactors and pressurized gas handling.

- Food & Beverage Industry – Maintains controlled environments in steam sterilization and production lines.

- Pharmaceuticals – Regulates pressure in purification, filtration, and compressed air systems.

Why Choose High Pressure Pop Type Safety Valves?

These valves are an indispensable safety component in industrial systems, providing quick, reliable, and automatic pressure relief. Their high durability, efficiency, and compliance with safety regulations make them the preferred choice across multiple industries.

For businesses looking for high-quality safety valves, choosing a trusted manufacturer ensures superior performance and longevity. Investing in well-designed safety valves enhances system reliability, reduces maintenance costs, and ensures operational safety in high-pressure environments.

By integrating High Pressure Pop Type Safety Valves into industrial operations, companies can safeguard equipment, optimize performance, and meet stringent safety requirements.

Description | Features |

|---|---|

TYPE: Pop Type End Connection: Thread Connection (BSP, BSPT, NPT, etc.) Size: 15NB - 200NB Pressure Range : 0 to 21Barg Temperature Range : -20*C to 250*C Body Materials: Stainless Steel, Carbon Steel, Brass, etc. Design Standards: API 520, API 526, API 527, EN ISO 4126 Part.1, ASME Section VIII Div. I, etc. Operation: Direct Spring Operated & Pop Type action. Flow Capacity: Up to 50,000 SCFM Certification: CE Certified under Category IV Module H (2014/68/EU) |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a pop-type safety valve?

- How does a it work?

It remains closed until the pressure in the system exceeds a preset level, causing the valve to "pop" open and release the excess pressure.

- What are main applications of it?

They are used to protect equipment and systems from overpressure conditions, preventing damage and ensuring safety.

- What are the main components of it?

The main components include the valve body, spring, disk or piston, and the seat where the disk or piston rests when the valve is closed.

- Where are these valves commonly installed?

They are installed in industrial systems such as boilers, pressure vessels, pipelines, and process equipment where pressure relief is critical.

- What Are the Benefits of Using One?

Pop-type safety valves provide critical overpressure protection, ensuring equipment and personnel safety by reliably venting excess pressure. They are essential in preventing damage to systems, maintaining operational integrity, and complying with safety regulations.

- How Do I Choose the Right One for My Application?

Choose a pop-type safety valve based on your system's pressure ratings, fluid type, temperature range, and flow requirements. Ensure it complies with relevant standards and is sized correctly for effective overpressure protection.

- Can They Be Repaired?

Yes, they can be repaired by replacing worn components such as springs, disks, or seats, but repairs should be conducted by qualified personnel.

- What Maintenance Is Required?

Maintenance includes regular inspections, cleaning, and testing to ensure the valve operates correctly and meets safety standards.

- Why to choose Freture to buy it from?

Freture has years of experience in valve manufacturing. We understand the importance of safety in every industry, and as a leading safety valve manufacturer, we provide the best solutions to your flow control and safety problems with cutting-edge technology and a team of experts. Freture is always committed to providing exceptional solutions through our service.

Industries where Pop Type Safety Valve is used

Water Treatment

Power Generation

Oil and Gas Industry

Boiler and Reactor

Petrochemical

Applications

- Pressure vessels: Ensuring safe operation by releasing excess pressure.

- Process industries: Safeguarding equipment and personnel from overpressure situations.

- Boilers: To protect against overpressure in steam systems.

- Oil and Gas Industry: Protects storage tanks, pipelines, and wellheads from overpressure during production and transport.

- Steam Generators: Ensures safe steam pressure levels to avoid equipment damage.