It is a device used to automatically release pressure from a system when it exceeds a predetermined limit, ensuring the protection of equipment and personnel.

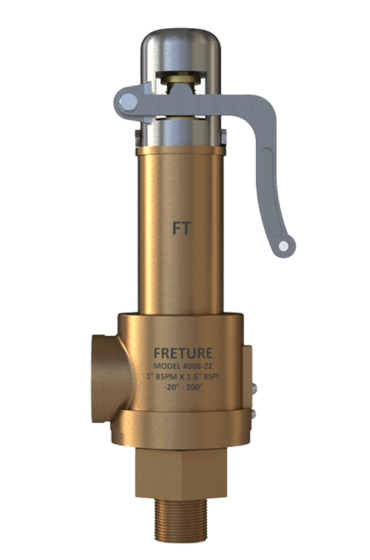

Safety Valves

Guarantee safety and peace of mind.

We are a leading High Pressure Safety Valve manufacturer in Mumbai, India, specializing in critical solutions for industries like oil and gas, pharmaceuticals, petrochemicals, and power plants.

Ensuring utmost safety and reliability, High Pressure Relief Safety Valves are meticulously engineered to mitigate risks associated with overpressure. Designed to protect your operations and personnel, our valves adhere to stringent industry standards, offering peace of mind in hazardous environments.

Count on our expertise to deliver customized solutions that optimize performance and compliance with regulatory requirements. Safeguard your processes with our proven, durable valves that ensure uninterrupted operations and minimize downtime, reinforcing your commitment to safety and operational excellence.

Explore Types of Pressure Safety Valve

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a High Pressure Safety Valve?

- How Does It Work?

It operates by opening at a set pressure to allow excess fluid or gas to escape, thereby preventing system pressure from exceeding safe levels. Once the pressure returns to normal, the valve closes.

- What Are the Main Applications?

They are used in a variety of industries, including oil and gas, chemical, pharmaceutical, and power generation, to protect boilers, pressure vessels, pipelines, and other pressurized systems.

- What Are the Benefits of Using One?

They enhance system safety by preventing overpressure conditions, protecting equipment from damage, and ensuring the safety of personnel. They also help maintain system integrity and compliance with industry regulations.

- What Materials Are Used in Their Construction?

They are typically constructed from materials such as stainless steel, carbon steel, and alloy steels, chosen for their durability and compatibility with various process conditions.

- How Do I Choose the Right One for My Application?

They based on your system’s pressure, temperature, and fluid characteristics. Ensure the valve’s material and design meet the specific requirements of your application and comply with relevant industry standards.

- Can They Be Repaired?

Yes, they can be repaired. Regular maintenance and inspection can identify issues early, and manufacturers often provide repair kits and services to restore valve functionality.

- What Maintenance Is Required?

Regular maintenance includes periodic testing, inspection for wear and corrosion, cleaning, and recalibration. Adhering to a maintenance schedule ensures reliable operation and extends the valve's service life.

- Are They Available in Different Designs?

Yes, they are available in various designs, including spring-loaded, pilot-operated, and balanced bellows types, to suit different applications and pressure ranges.

- Why Is Freture the Best Place to Buy From?

Freture Techno Pvt. Ltd. offers high-quality safety valves designed to meet stringent industry standards. With expert technical support, a wide range of products, and a commitment to customer satisfaction, Freture is your reliable partner for high-performance valve solutions.

Industries where a Safety Valves is Used

Oil and Gas Industry

Chemical Processing

Pharmaceutical Industry

Power Generation

Food and Beverage

Applications of High Pressure Safety Valve

- Boiler Protection: Prevents overpressure in steam boilers, ensuring safe operation and preventing potential explosions.

- Process Equipment Safety: Protects chemical reactors, storage tanks, and pressure vessels from exceeding design pressure limits.

- Pipeline Systems: Ensures safe pressure levels in gas and liquid pipelines, preventing leaks and ruptures.

- Pharmaceutical Manufacturing: Maintains pressure control in bioreactors and sterilizers, ensuring product quality and safety.

- Power Plant Systems: Safeguards steam turbines, condensers, and other critical components from overpressure conditions.