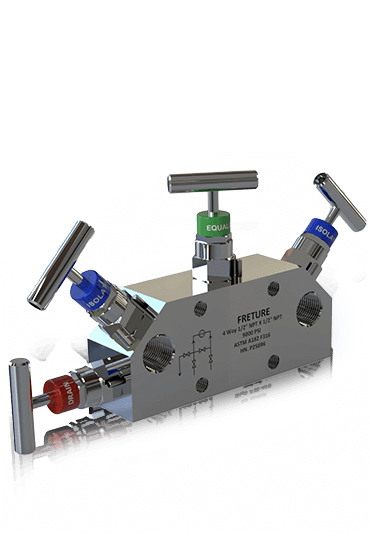

A 4 way manifold is a device used in fluid control systems to distribute or collect fluid flow from multiple sources or to multiple destinations. It typically consists of a central body with four ports, allowing for the connection of various fluid lines.

4 Way Manifold Valve

Versatile Fluid Distribution:4 way Manifold Mounted Valves

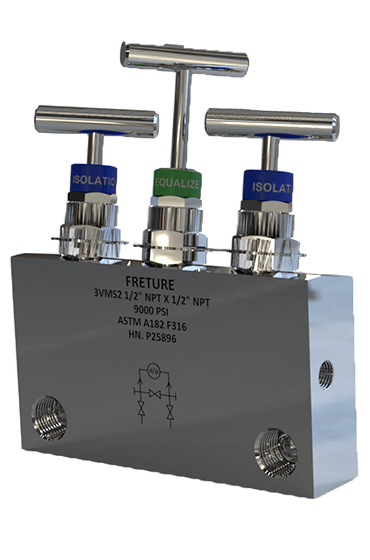

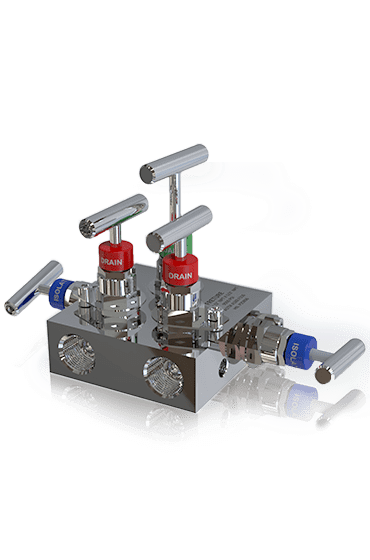

We are a leading 4 Way Manifold Valve manufacturer in Mumbai, India, designed to streamline fluid control systems in various industries. This manifold efficiently directs fluid flow from a single inlet to four separate outlets or from four inlets to a single outlet (Four Way Manifold), providing exceptional versatility and control in fluid distribution processes.

Crafted with precision, our 4 Way Manifold Valve features robust construction, ensuring durability and reliability even in the most demanding industrial environments. It is manufactured using high-quality materials such as stainless steel, brass, or carbon steel, guaranteeing corrosion resistance and compatibility with a wide range of fluids.

The 4-Way Manifold finds applications across diverse industries including oil and gas, chemical processing, water treatment, pharmaceuticals, and more.

Choose Freture Techno for your fluid control needs and benefit from our commitment to excellence. 4 Way Manifold valve are engineered to the highest industry standards, offering unmatched quality, reliability, and performance.

Description | Features |

|---|---|

TYPE: 4 Way Manifold Valve (S / T / H / Coplanar) End Connection: Flange / Butt Weld Size: 15 NB - 300 NB Pressure Rating: 150PSI -6,000PSI Temperature Range: -7Deg C to 280 Deg C Body Materials: Stainless Steel / Carbon Steel / Alloys Design Standard: MSS Sp99 End Connection Std.: ASME B16.5 / B16.11 / B16.25 / ANSI 1.20.1 Face to Face: ASME B16.10 Rev 2009 Fire safe design: API-607 Rev 2010 Safety: NACE MOR 0175 , BS/EN 10204-3.1 REV 2004, API 598 Rev 2009, API-607 |

|

Related Products

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a 4 way Manifold?

- How does it work?

A 4 way manifold works by directing the flow of fluids from multiple input sources to different output destinations or vice versa. It effectively manages the distribution or collection of fluid flow, providing flexibility and control in fluid systems.

- What are the main applications?

4 way manifolds find primary applications in fluid control systems across various industries, including oil and gas, chemical processing, water treatment, and hydraulic systems. Manifold Valves are used for pressure and flow control, fluid distribution, and fluid isolation tasks.

- What are the benefits of using one?

The benefits of using a 4-way manifold include efficient fluid distribution, simplified piping layouts, reduced installation time and costs, enhanced system flexibility, and improved overall system performance.

- What materials are used in their construction?

4-way manifolds are commonly constructed from materials such as stainless steel, brass, aluminum, or thermoplastics, depending on the specific application requirements and compatibility with the fluid being handled.

- How do I choose the right one for my application?

Choosing the right 4-way manifold involves considering factors such as the type of fluid, pressure and temperature requirements, flow rates, compatibility with the existing system, and the specific application needs. Our technical experts can assist in selecting the most suitable manifold for your requirements.

- Can they be repaired?

Yes, 4-way manifolds can often be repaired. Maintenance and repair may involve replacing damaged components, such as seals or valves, and ensuring proper alignment and functionality.

- What maintenance is required?

Regular maintenance of 4-way manifolds typically includes inspection, cleaning, and lubrication of moving parts, checking for leaks, and ensuring proper functionality. Following a preventive maintenance schedule can help prolong the manifold's lifespan and maintain optimal performance.

- Are they available in different designs?

Yes, 4-way manifolds are available in various designs to suit different application requirements. These designs may include different port sizes, connection types, materials, and configurations to meet specific system needs.

- Why is Freture the best place to buy from?

Freture is the best place to buy 4-way manifolds due to our commitment to providing high-quality products, expert technical support, competitive pricing, and exceptional customer service. Our 4-way manifolds are designed and manufactured to the highest industry standards, ensuring reliability, durability, and performance in diverse industrial applications.

Industries where 4 Way Manifold Valve is used

Oil and Gas Industry

Chemical Processing Industry

Water Treatment Industry

Pharmaceutical Industry

Food and Beverage Industry

Applications of 4 Way Manifold Valve

Fluid Distribution: 4-way manifold are commonly used to distribute fluids from a single source to multiple destinations or from multiple sources to a single destination in various fluid control systems.

Pressure Regulation: They play a crucial role in regulating pressure by dividing or combining the flow of fluids from different sources, allowing for precise control over pressure levels in hydraulic and pneumatic systems.

Fluid Isolation: 4-way manifolds are utilized for fluid isolation tasks, enabling the diversion of fluid flow to specific components or sections of a system while isolating others for maintenance or repair.

Fluid Sampling: In industries such as chemical processing and oil and gas, 4-way manifold are used for fluid sampling applications, facilitating the collection of fluid samples from different points in a system for analysis or testing.

System Integration: They are essential components for integrating multiple fluid lines into a single system, providing a compact and efficient solution for managing fluid flow in various industrial processes.