It is a type of valve that allows fluid to flow in one direction only, preventing backflow and ensuring unidirectional flow in a system.

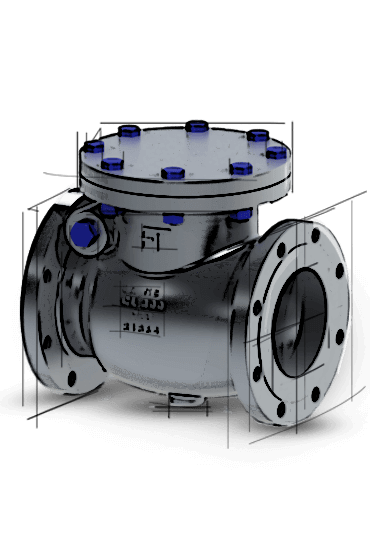

Check Valves

Manufactured Check Valves: Ensuring One-Way Flow and Preventing Backflow in Pipeline Systems

Freture is a leading Check Valve manufacturer in Mumbai, India. Renowned for its commitment to quality and innovation, Freture offers a comprehensive range of Check Valves designed to ensure fluid flow in a singular direction, preventing backflow and safeguarding system integrity.

They are types of valves that allow fluid to flow through them in only one direction. They are commonly used in piping systems to prevent backflow or reverse flow of fluids, which can cause damage or contamination. Industrial Check valves work by using a disc or a ball that opens and closes based on the pressure of the fluid. When the fluid flows in the desired direction, the disc or ball is pushed open, allowing the fluid to pass through. When the flow of fluid tries to reverse, the disc or ball is forced closed, preventing backflow.

There are different types of check valves such as Swing Check Valves, Tilting Disc Check Valves, Lift Check Valves, Piston Check Valve, Dual plate Check valves, and others, each with its own advantages and disadvantages depending on the application. Check valves can be found in various industries, including chemicals, oil and gas, water treatment, and many others.

Features include:

- One-way flow: The valves that allow flow in one direction only, preventing the backflow of fluids.

- Simple design: The valves have a simple design, consisting of a disc or ball that moves in response to fluid pressure, making them reliable and easy to maintain.

- Low-pressure drop: They have a low-pressure drop, which means they cause minimal resistance to the flow of fluid.

- Various materials: They are available in a range of materials such as metal, plastic, and rubber, making them suitable for use with different fluids and environments.

- Different types: they come in different types such as swing check, tilting disc check, lift check, and ball check valves, each with unique features and advantages.

- Versatile applications: They are used in various industries such as oil and gas, water treatment, chemical, and pharmaceutical, and can be used in different systems such as pumps, compressors, and pipelines.

- Automatic operation: They operate automatically, responding to changes in fluid pressure without the need for manual intervention.

Types of Check valves

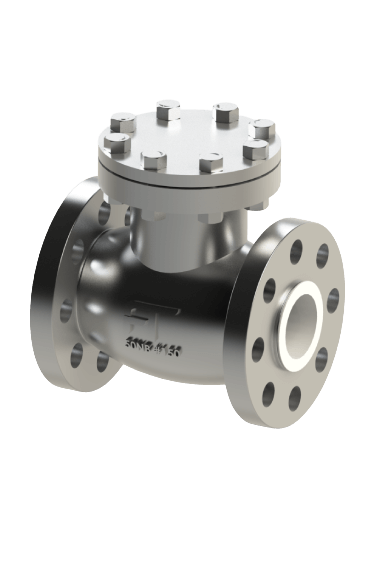

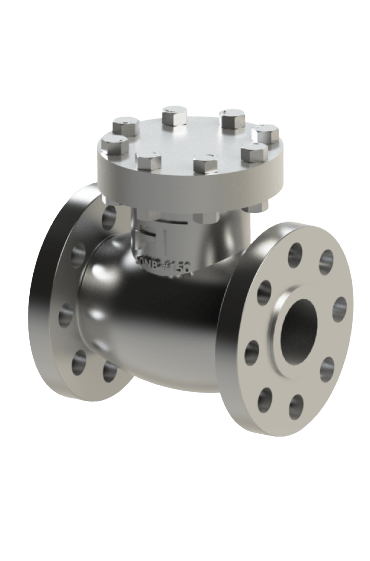

- Swing Check Valve: This type of check valve has a swinging disc that opens in the direction of fluid flow and closes when the flow is reversed. It operates using gravity and fluid pressure, making it suitable for use in low-pressure applications.

- Lift Check Valve: This type of check valve has a disc that is lifted from its seat to allow fluid flow in one direction. The disc is then lowered back onto the seat to prevent reverse flow.

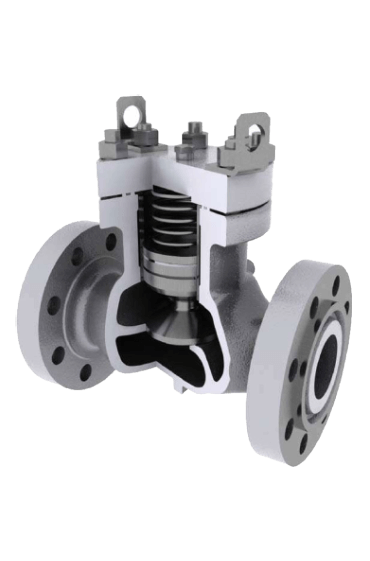

- Piston Check Valve: This type of check valve uses a piston to allow or prevent fluid flow. When the pressure in the upstream side is higher than the downstream, the piston lifts, allowing fluid to flow through the valve. When the pressure in the downstream side is higher, the piston returns to its seat, preventing backflow.

- Lined Check Valve: This type of check valve is lined with a corrosion-resistant material such as PTFE (polytetrafluoroethylene) or rubber, making it suitable for use in corrosive applications.

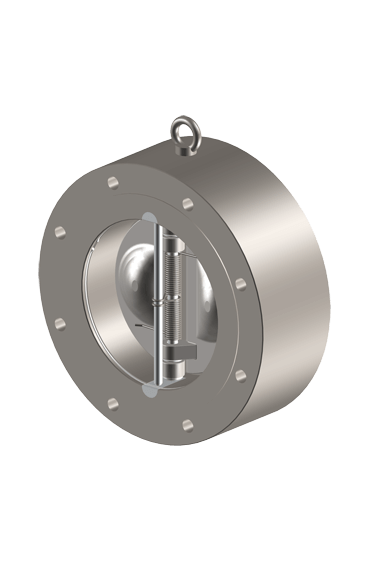

- Dual Plate Check Valve: This type of check valve has two spring-loaded plates that move away from the seat in response to fluid flow in one direction, and then return to their original position to prevent reverse flow. This design results in a compact and lightweight valve suitable for use in high-pressure applications.

There are also other types of check valves such as ball check valves, diaphragm check valves, and wafer check valves, each with its own unique features and advantages. The selection of the appropriate type of check valve depends on the specific application and operating conditions.

Applications of the Check Valve

They are used in a wide range of industries where the flow of fluids or gases needs to be regulated in a single direction. Some common industries where this valves are used include: Oil and Gas: They are used in oil and gas production, refining, and transportation systems to prevent backflow of fluids and gases.

- Water and Wastewater: They are used in water treatment and distribution systems to prevent backflow and contamination of potable water.

- Chemical Processing: They are used in chemical processing plants to regulate the flow of chemicals and prevent backflow or cross-contamination.

- HVAC: They are used in heating, ventilation, and air conditioning systems to prevent the reverse flow of fluids and gases.

- Power Generation: They are used in power generation plants to control the flow of steam, water, and other fluids in turbines and other equipment.

- Marine and Shipbuilding: They are used in marine and shipbuilding industries to regulate the flow of fluids and gases in piping systems.

- Food and Beverage: They are used in the food and beverage industry to prevent backflow and contamination in processing and distribution systems.

- Pharmaceutical: They are used in pharmaceutical manufacturing to control the flow of fluids and prevent contamination.

- Pulp and Paper: They are used in the pulp and paper industry to regulate the flow of chemicals, water, and other fluids in the manufacturing process. Overall, They are used in any industry where the prevention of backflow is critical for safety, environmental protection, and efficient operation of systems.

Why Choose Freture Techno

We are committed to quality, customization options, expert guidance, reliability, competitive pricing, wide industry application, proven track record, and global reach. With Freture Techno, you get top-tier, tailored manufacturer of Industrial check valves backed by a team of experts, ensuring the efficiency and reliability of your operations.

Explore Types of Check Valves

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Check Valve?

- How does a this Valve work?

They operates automatically, opening when the fluid flows in the desired direction and closing when there is a reversal of flow. This is typically achieved through a spring-loaded mechanism or gravity.

- What are the main applications of this Valves?

They are used in various applications, including water and wastewater treatment, chemical processing, oil and gas, HVAC systems, and power generation, to prevent backflow and protect equipment.

- What are the benefits of using a this Valve?

Benefits include preventing backflow, protecting pumps and compressors, ensuring system integrity, reducing maintenance, and prolonging the lifespan of the equipment

- What materials are used in this Valves?

They are made from materials such as stainless steel, carbon steel, cast iron, bronze, and various polymers, depending on the application and the type of media being handled.

- How do I choose the right the Valve for my application?

Consider factors such as the type of fluid, operating pressure and temperature, flow rate, material compatibility, and the specific requirements of your system to select the appropriate Check Valve.

- Can this Valves be repaired?

Yes, they can be repaired. However, the feasibility and cost-effectiveness of repair depend on the valve type and extent of damage. It is recommended to consult with a professional for proper assessment and repair.

- What maintenance is required for this Valves?

Regular inspection and cleaning are required to ensure optimal performance. Maintenance may also include checking for wear and tear, ensuring the valve closes properly, and replacing any damaged components.

- Are this Valves available in different designs?

Yes, they are available in various designs, including swing check valves, lift check valves, ball check valves, and dual plate check valves, each suited for different applications and flow requirements.

- Why is Freture the best place to buy Check Valves from?

Freture offers high-quality Check Valves made from superior materials, a wide selection of designs to meet diverse needs, expert support for optimal valve selection, competitive pricing, and excellent after-sales support and warranty services.

Industries Where this Valves Are Used

Applications of Check Valve

- Preventing Backflow: Ensures fluid flows in one direction only, preventing backflow.

- Pump Protection: Protects pumps by preventing reverse flow when the pump is shut down.

- Water Systems: essential in water systems to prevent backflow, contamination, and flooding.

- Steam Systems: Used to prevent reverse flow of steam in steam systems.

- Hydraulic Systems: Maintains system pressure and prevents reverse flow in hydraulic systems.