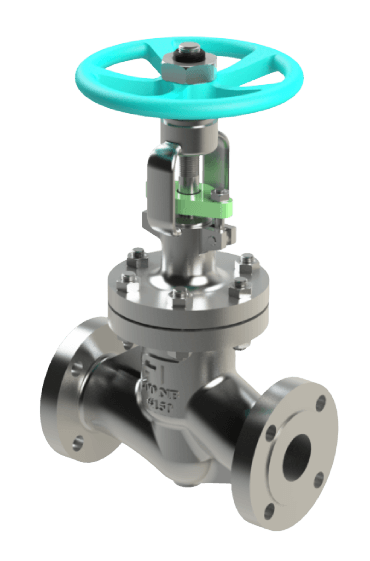

A lined Globe valve regulates fluid flow and is lined with materials like FEP, PFA, PTFE for corrosion resistance, making it ideal for handling aggressive chemicals in various industrial applications.

Lined Globe Valve

Secure Fluid Handling with Fretures Lined Globe Valve

We are leading PVDF, FEP, PFA, and PTFE Lined Globe Valve Manufacturers in India. They are crucial for industries requiring precise flow control and excellent corrosion resistance. Featuring a robust construction with a lining made from materials such as FEP, PFA, PTFE and PVDF , these valves excel in handling aggressive chemicals and corrosive fluids, making them ideal for industries like chemical processing, pharmaceuticals, and water treatment.

Freture guarantees optimal performance in industrial operations with standards like ASME,ISO and API. Making sure durable lining not only extends the valve's lifespan but also ensures minimal maintenance and reduces the risk of leaks. By providing accurate regulation of fluid flow, PTFE Lined Globe Valves enhance operational efficiency and safety. Freture lined Globe valves versatility in size, pressure ratings, and connection types allows for seamless integration into various systems

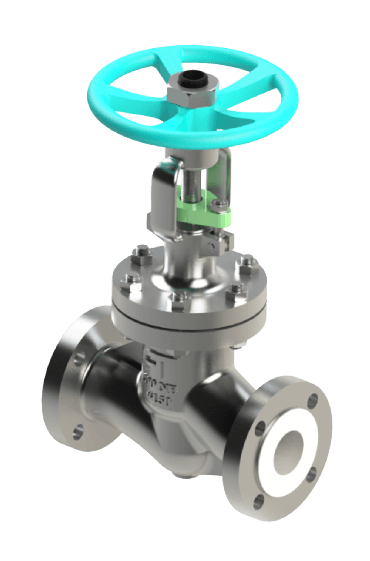

PFA Globe Valve – Corrosion-Resistant Precision Flow Control

A PFA Globe Valve is designed for precise flow regulation in highly corrosive environments. Featuring a durable PFA (Perfluoroalkoxy) lining, this valve ensures exceptional resistance to harsh chemicals, high temperatures, and aggressive media, making it ideal for critical industrial applications.

Key Features:

✔ Superior Corrosion Resistance – PFA lining protects against acids, alkalis, and volatile chemicals.

✔ Efficient Flow Control – Globe valve design enables precise throttling and minimal pressure drop.

✔ High-Temperature Tolerance – Suitable for demanding thermal conditions.

✔ Leak-Proof Sealing – Ensures enhanced system safety and reliability.

Applications:

✅ Chemical Processing | ✅ Pharmaceuticals | ✅ Water Treatment

With low maintenance requirements and extended durability, PFA Globe Valves offer a long-term solution for handling aggressive media. Contact Freture Techno PFA Globe Valve manufacturer in Mumbai, India, for high-quality solutions tailored to your needs.

Specifications | Features |

|---|---|

Type: Lined Globe Valve End Connection: Flanged ( ASME B16.5 ) Size: 15NB - 600NB Class: 150# - 2500# Temperature: -20°C to 200°C (-4°F to 392°F) Material: Cast Iron, Stainless Steel, Carbon Steel Lining Material: PTFE, PFA, FEP, PVDF Leakage Rate: ANSI Class VI Seat: Nitrile, PTFE, Reinforced PTFE, Metal Safety Standards: BS/EN, NACE, API 598 Rev 2009, ISO 5208, and API 607 Rev 2010 | Corrosion Resistance: Lined with materials like PTFE for handling corrosive fluids. Low Friction Operation: Smooth piston movement reduces friction for efficient flow. Environmental Protection: Minimizes the risk of environmental contamination. Versatile Applications: Suitable for various industries including chemicals, pharmaceuticals, and water treatment. Long Service Life: Durable construction for extended operational lifespan. Precise Flow Control: Provides accurate regulation of flow rates. High Flow Capacity: Allows for efficient flow even at high pressures. Safety Features: Helps prevent accidents and protects equipment from damage due to reverse flow. |

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is Lined globe Valve?

- How does it work?

A FEP, PFA, PTFE lined globe valve controls flow by moving a disc into or out of the fluid path using a handwheel or actuator. The lining provides resistance to corrosive fluids, ensuring reliable operation.

- What are the main applications?

FEP, PFA, PTFE Lined globe valves are used in industries like chemical processing, pharmaceuticals, food and beverage, water treatment, pulp and paper, and oil and gas, particularly where corrosion resistance is essential.

- What are the benefits of using one?

Benefits include excellent corrosion resistance, durability, leakage prevention, and precise flow control, making them ideal for handling corrosive fluids in demanding industrial environments. - What materials are used in their construction?

Construction materials include a metal body (cast iron, stainless steel), a lining (PTFE, PFA), and components like stems and discs made from corrosion-resistant alloys.

- How do I choose the right one for my application?

Consider fluid compatibility, pressure and temperature ratings, valve size, end connections, and actuation method to ensure the valve meets your specific operational requirements.

- Can they be repaired?

Yes, lined globe valves can be repaired by replacing the lining, seats, and other internal components, following the manufacturer’s guidelines to maintain performance and integrity.

- What maintenance is required?

Maintenance includes regular inspections, cleaning, lubrication of moving parts, and checking for leaks to ensure the valve operates efficiently and maintains its corrosion resistance.

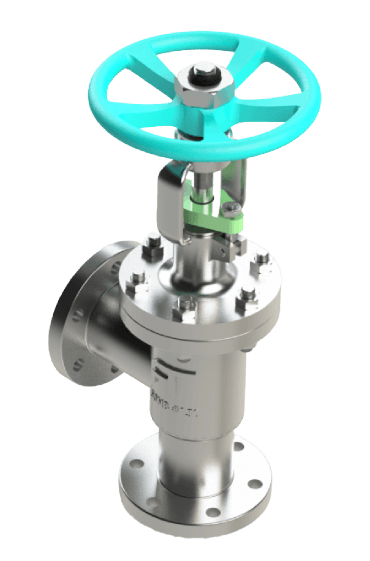

- Are they available in different designs?

Yes, designs include straight pattern, angle pattern, and Y-pattern, each suited for different flow requirements and installation configurations in various industrial applications.

Freture offers high-quality valves, a wide selection, expert support, competitive pricing, and reliable service, ensuring you find the right valve for your needs with excellent customer care.

Industries where Lined Globe Valve is Used

Chemical Processing

Petrochemical Industry

Pharmaceutical Industry

Water Treatment

Food And Beverage Industry

Applications of Lined Globe Valve

- Corrosive Fluid Handling: Used for handling corrosive fluids in chemical processing and petrochemical industries.

- Abrasive Media Control: Employed for controlling abrasive media in mining, mineral processing, and water treatment.

- High-Purity Fluid Control: Utilized for controlling high-purity fluids in pharmaceuticals and food processing.

- Temperature Control Applications: Used in HVAC systems and thermal power plants for temperature regulation.

- Corrosive Gas Handling: Suitable for handling corrosive gases in semiconductor manufacturing.