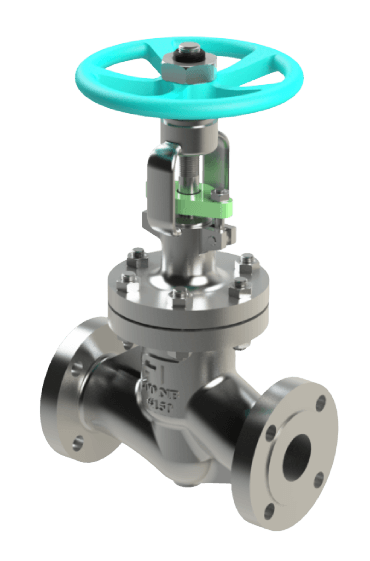

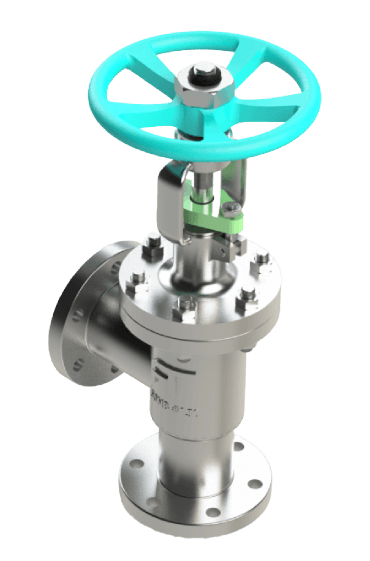

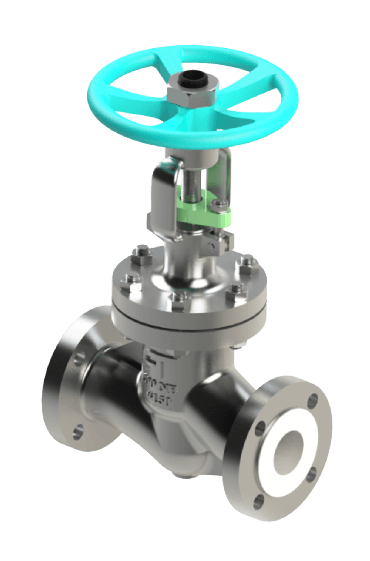

A forged globe valve controls fluid flow in pipelines using a movable disk and ring seat in a spherical body.

Forged Steel Globe Valve

Forge Your Flow, Secure Your System

We are leading API 602 / 623 Forged Steel Globe Valve manufacturers in Mumbai, India. A forged globe valve is specially designed to regulate the flow of liquids or gases in pipelines. Constructed through forging, which uses localized compressive forces to shape metal, these valves are stronger and more durable than cast valves.

They are highly valued in industrial applications for their robustness and reliability. They are widely used in industries such as oil and gas, power generation, chemical processing, and water treatment for flow regulation, especially in high-pressure and high-temperature environments, due to their strength and resistance to wear and corrosion. Operators adjust the flow rate by turning a handwheel, which moves the disk closer to or further from the seat.

Durability and Resistance in Industrial Applications

They are known for their versatility and efficiency in various industrial applications. Unlike gate valves, which are primarily used for on/off control, globe valves are ideal for throttling, allowing operators to precisely control the flow rate. The internal design of a globe valve includes a disc and seat, with the disc moving parallel to the flow of fluid. This configuration helps in reducing erosion of the seating surfaces and ensures a longer lifespan for the valve.

They are highly resistant to wear, corrosion, and mechanical stress due to the forging process. This makes them well-suited for industries where harsh operating conditions are common, such as in petrochemical plants, refineries, and power stations. They also exhibit low torque requirements for operation, meaning less force is needed to adjust the valve’s position, which contributes to energy savings in automated systems.

Another advantage of these valves is their adaptability to different media types, including steam, water, gas, and corrosive chemicals. They can be customized with various materials, such as stainless steel, carbon steel, or special alloys, to match the specific requirements of an application. Furthermore, they can be equipped with manual, electric, or pneumatic actuators for added operational flexibility.

Easy Maintenance and Long Lifespan

Maintenance is also relatively simple for forged steel globe valves, as they are designed with easy access to internal components, facilitating inspection and repair. Due to their reliable sealing capabilities, they significantly minimize the risk of leaks, which is essential for ensuring safety and reducing downtime in critical industrial processes.

Why Choose Freture Techno Pvt. Ltd.?

When considering where to source forged globe valves, Freture Techno Pvt. Ltd. stands out as a leading API 602 Forged Steel Globe Valve manufacturer India. With a commitment to high-quality materials and advanced forging techniques, the company produces valves designed for long-term durability and efficiency. Freture Techno Pvt. Ltd. also ensures strict adherence to international standards, providing solutions tailored to meet specific industry needs. Their focus on customer satisfaction, technical expertise, and reliable post-sales support makes them a trusted partner for industries requiring Forged steel Globe Valves.

Specifications | Features |

|---|---|

Type: Forged Steel Globe valve End Connection: Flanged, Butt Weld, Socket Weld, Threaded (ASME B16.5 / B16.11 / B16.25 / ANSI 1.20.1) Size: 15NB - 600NB Class: 150# - 2500# Temperature: -29°C to 593°C Material: Carbon Steel, Stainless Steel, Alloy Steel Design Standard: API 623 / API 602 / BS 1873 Leakage Class: ANSI Class IV, V, VI Seat: Stainless Steel, Stellite, Tungsten Carbide Safety Standards: BS/EN, NACE, API 598 Rev 2009, ISO 5208, API 607 Rev 2010 | Robust Construction: Built using forging processes, ensuring strength and durability. Compact Design: Takes up less space compared to other valve types. Smooth Flow Control: Allows precise regulation of fluid flow. Tight Shut-Off: Provides excellent sealing capabilities when closed. Corrosion Resistance : Resistant to rust and corrosion in harsh environments. Forged Construction: Provides strength and durability. High Pressure Capability: Can withstand high pressure conditions. Ease of Operation: Simple to operate and adjust. Longevity: Has a long service life due to its robust construction. Safety: Helps prevent leaks and ensures safe operation. |

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is Forged Globe Valve?

- How does it work?

It throttles flow by moving the disk closer or away from the seat using a handwheel or actuator.

- What are the main applications?

Used in oil & gas, power generation, chemical processing for flow control in high-pressure systems.

- What are the benefits of using one?

Offers robust construction, precise flow control, durability, and reliability in demanding environments.

- What materials are used in their construction?

Carbon steel, stainless steel, alloy steel for strength, corrosion resistance, and longevity.

- How do I choose the right one for my application?

Consider factors like pressure rating, temperature range, end connections, and material compatibility.

- Can they be repaired?

Yes, they can undergo repairs such as replacing seats, seals, or trim components.

- What maintenance is required?

Regular inspection, lubrication of moving parts, and replacing worn-out components as needed.

- Are they available in different designs?

Yes, including bolted or welded bonnet, various end connections, and optional actuators

- Why is Freture the best place to buy from?

Freture offers a wide selection, quality assurance, and expert support for your valve needs, ensuring reliability and customer satisfaction.

Industries where Forged Globe Valve is Used

Oil and Gas Industry

Power Generation

Chemical Processing

Water Treatment Plant

Petrochemical Industry

Applicatiions of Forged Globe Valve

Boiler Feed Water Control: Ensuring precise regulation of water flow in boiler systems to maintain operational efficiency and safety.

Steam Control: Used to regulate steam flow and pressure in power generation plants and industrial processes to optimize performance.

Process Control: Critical for controlling flow rates of various fluids in chemical processing plants to maintain process efficiency and product quality.

Oil and Gas Pipelines: Essential for controlling the flow of crude oil, natural gas, and refined products through pipelines, ensuring safe and efficient transport.

Cooling Water Systems: Used in cooling water circuits of power plants and industrial facilities to manage water flow and temperature for equipment cooling.