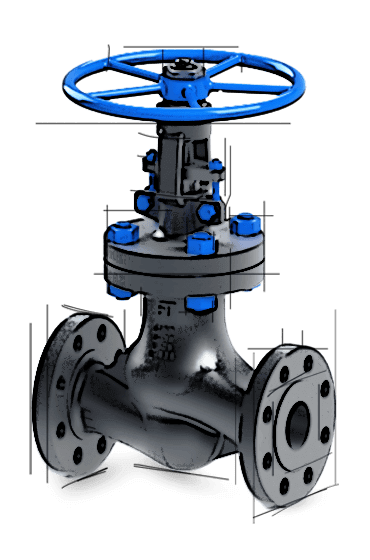

It is a type of linear motion valve used to control the flow of fluids or gases within a pipeline. It features a disk or plug that moves perpendicular to the flow, allowing for precise regulation of flow rate.

Globe Valve

A type of linear motion valve is used to stop, start, and regulate fluid flow.

Freture Techno is a leading Globe Valves manufacturer in Mumbai, India. These Valves are fundamental in controlling the flow of fluids within pipelines and systems. Their unique design comprises a spherical body with an internal baffle, allowing for precise regulation of flow rates. By altering the position of the internal disc, Globe valves can either restrict or permit fluid passage, making them an essential choice in various industries.

How Globe Valve Work:

The operation of these valves is both simple and effective. When the handwheel or actuator is turned, the internal disc moves either closer to or farther away from the Valve seat. This movement regulates the flow of fluid through the valve. When the disc is fully raised, the valve is in the open position, allowing for maximum flow. Conversely, when the disc is fully lowered, the valve is closed, cutting off the flow entirely.

Types of Gate Valves:

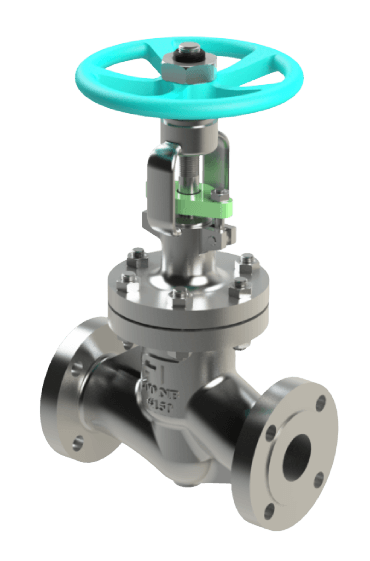

- API Globe Valve – Manufactured as per API 623 / API 602 / BS 1873 standards, available in flanged, threaded, socket, and butt weld connections, with sizes from 15NB to 600NB and pressure ratings of 150# to 2500#.

- Forged Globe Valve – Built for high-performance applications, featuring flanged, butt weld, socket weld, and threaded connections.

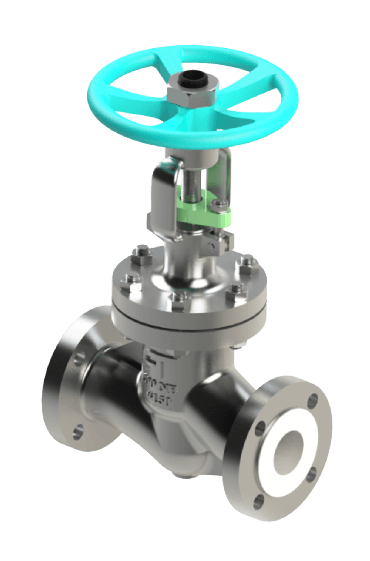

- PTFE Lined Globe Valve – Corrosion-resistant, lined with PTFE, PFA, FEP, ETFE, and PVDF for aggressive media.

- Pressure Seal Globe Valve – Ideal for high-pressure applications, offering exceptional sealing.

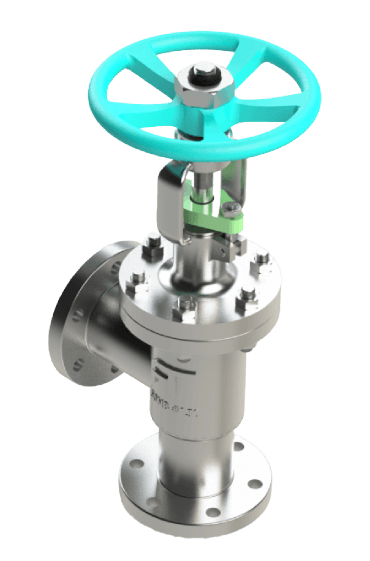

- Angle Globe Valve – Available in Angle, "T" Type, and "Y" Type designs, ensuring flexibility in piping systems.

Key Features:

- Precise Control: It offers unparalleled control over fluid flow, making it ideal for applications where accurate regulation is crucial.

- Durability: It is built to last, with robust materials and craftsmanship that ensure longevity even in the harshest conditions.

- Low Maintenance: It's designed for minimal maintenance, reducing downtime and operational costs.

- Wide Range of Materials: Available in a variety of materials, including stainless steel, carbon steel, and bronze, to suit different applications.

- Leakage Prevention: Their advanced design minimizes the risk of leakage, enhancing system reliability and safety.

Applications:

Find extensive use across numerous industries, including:

- Oil and Gas: They are crucial in controlling the flow of various fluids, such as crude oil and natural gas, in drilling and transportation processes.

- Water Treatment: It is employed in water treatment plants to regulate the flow of water, chemicals, and other fluids.

- Power Generation: In power plants, It plays a vital role in controlling steam and other fluids to optimize energy production.

- Chemical Processing: The precise control offered by It is essential in handling corrosive chemicals and substances.

- Pharmaceuticals: It ensures the precise dosing and control of pharmaceutical ingredients during production.

Why use Globe Valves

They are a type of linear motion valve widely used in various industries and applications due to their specific design and functional characteristics. Here are some reasons :

Precise Flow Control: It offers precise control over the flow of fluids, allowing for accurate adjustment of the flow rate through the valve. The throttling capability of a these valve is particularly useful in applications where precise flow regulation is essential.

Versatility: It can be used in a wide range of applications, including those involving steam, air, water, and various other fluids. They are suitable for both high and low-pressure systems.

Good Shutoff Capability: It provides a good sealing mechanism, which allows it to provide an effective shutoff, preventing or limiting the flow of fluid when the valve is fully closed.

Pressure Drop Management: It is effective in managing pressure drops in a system. By adjusting the valve opening, the pressure drop across the valve can be controlled, which is crucial in maintaining system performance and efficiency.

Ease of Maintenance: It is relatively simple in design and easy to maintain. They can be quickly disassembled, inspected, and repaired, making maintenance tasks more manageable and cost-effective.

Moderate to Good Leakage Control: It is a relatively good sealing capability, helping to minimize leakage when the valve is closed. This is especially important in applications where leakage is a concern, such as in applications involving hazardous or expensive fluids.

Reliability: It is known for their reliability and long service life, making them a popular choice in critical applications where consistent performance is essential.

Suitability for Throttling: It is well-suited for throttling or controlling the flow rate within a system. The design allows for precise adjustments to achieve the desired flow conditions.

Directional Flow Control: It is an unidirectional valves, meaning they are designed to control flow in one direction. This feature is important in applications where controlling the direction of flow is crucial.

Why Choose Freture Techno?

- Expertise: Freture Techno boasts decades of experience in valves manufacturing, ensuring top-notch quality and reliability.

- Custom Solutions: They offer tailor-made Globe valves solutions to meet the unique needs of your application.

- Global Presence: With a worldwide presence, Freture Techno can provide prompt and efficient support to clients around the Globe.

- Cutting-edge Technology: Their commitment to innovation ensures that you get access to the latest advancements in valves technology.

- Exceptional Service: Freture Techno is renowned for its exceptional customer service, providing support from selection to installation and beyond.

When it comes to Globe valve manufacturers in Mumbai, India, Freture Techno emerges as a leader in the industry. Our commitment to precision, durability, and customer satisfaction sets us apart as a reliable partner for all your fluid control needs. Choose Freture Techno for globe valves that excel in performance, longevity, and versatility.

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Globe Valve?

- How does a it work?

They operate by raising or lowering the disk or plug within the valve body. When the valve is fully open, the disk is lifted, permitting maximum flow. Closing the valve lowers the disk, restricting flow.

- In what industries They are commonly used?

Due to their precise throttling and flow control capabilities,They are used in various industries, including oil and gas, power generation, water treatment, HVAC systems, and more.

- What are the benefits of using one?

They are one of the most used valve in industries due to there simple yet highly beneficial design,It Give special ability to function flawlessly at extremely high temperatures and make them one of the safest valves used in Flow System.

At Freture, Are 100% leak-proof and emission free. Saves down-time and process media. Maintenance free. Easy to install and remove.

- Do I really need a this Valves for my factory?

If you want to improve efficiency with Safety, a Globe Valve is must,Specially in following Industries:

- Chemical Manufacturing

- Oil & Gas Refineries

- Boiler / Reactor Manufacturing

- Pharma/BioTech

If you’re from another industry looking for more details about how you can benefit from using a Globe Valve, please get in touch with Our Experts for further discussion.

- Can we use it for both upward and downward flow?

Yes, They are designed for both upward and downward flow. The flow direction is indicated by the arrow on the valve body, ensuring proper installation.

- Does it have automation?

Yes, various types of actuators, such as electric, pneumatic, or hydraulic are used to provide effective Automation service Automation enables remote operation, integration into control systems, and precise flow regulation.

- What is the difference between a Globe Valve and a Gate Valve?

While both are linear motion valves, the key difference is in the mechanism and flow control. A Globe valve controls flow by raising or lowering a disk perpendicular to the flow, allowing precise regulation. A Gate valve controls flow with a flat or wedge-shaped gate that moves parallel to the flow.

- Why is Freture the best place to get it from?

Our products are manufactured & Tested as per international Std. & we offered only best quality product

- We will keep stock of Std. Product for last minute urgency

- We provide products only from reputed & highly reliable manufactured

- We have an experienced technical team who will be able to understand client’s exact requirements & accordingly we will offer solutions

- How do I know which type of Globe Valve is ideal for me?

Considering fluid type, pressure, temperature, valve size, operation frequency, and Other applications can help you to select Best Globe valve configuration for your system.

You can also connect, with Experts here for a free consultation.

Industries where these Valve is Used

Oil and Gas Industry

Petrochemical

Power Generation

Water Treatment

Chemical Processing

Applications

- Flow Regulation: Used for flow regulation in various industries.

- Isolation: Effective for complete shut-off of fluid flow.

- Throttling: is suitable for precise control of flow rates.

- Boiler Feedwater Control: Used in power generation plants for controlling feedwater flow into boilers.

- Steam Systems: Employed in steam systems for regulating steam flow.