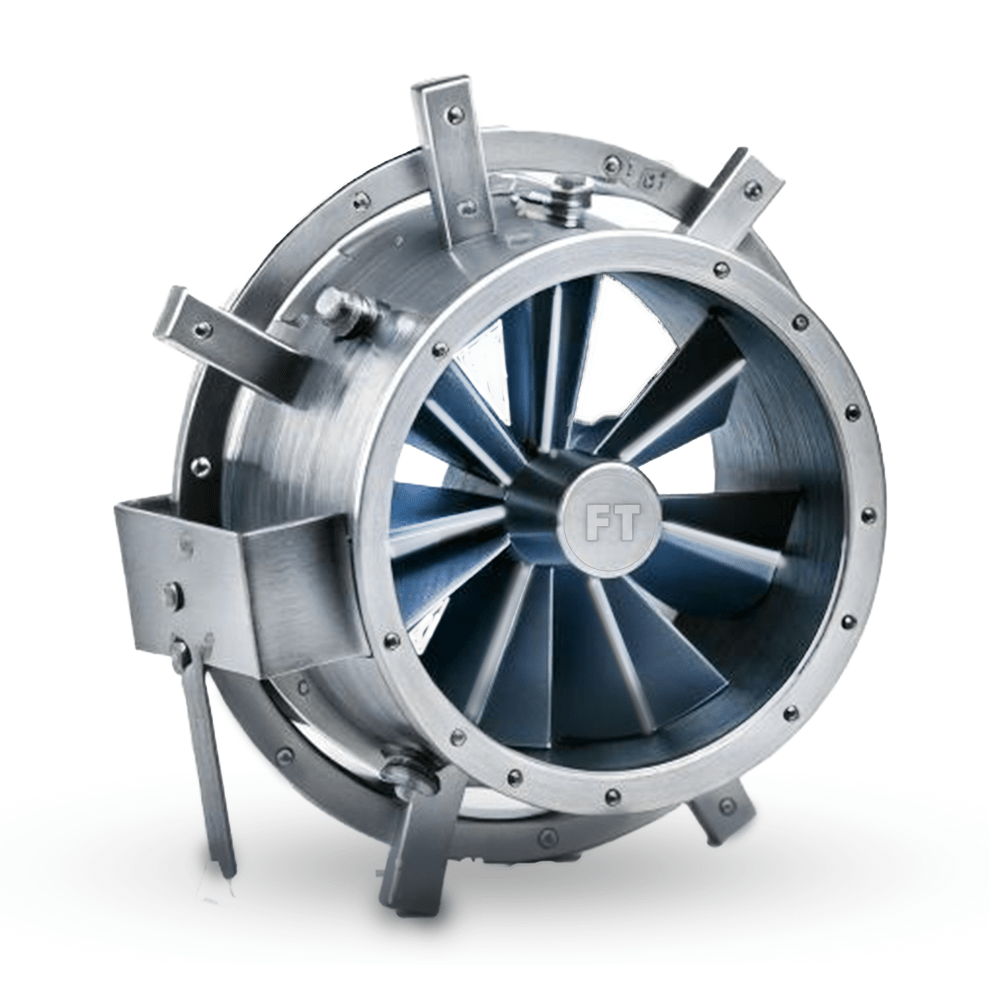

A Backdraft Damper is a safety device used to prevent reverse airflow in ventilation systems, ensuring that air flows in the correct direction.

Backdraft Damper

Block reverse airflow for safe, efficient ventilation

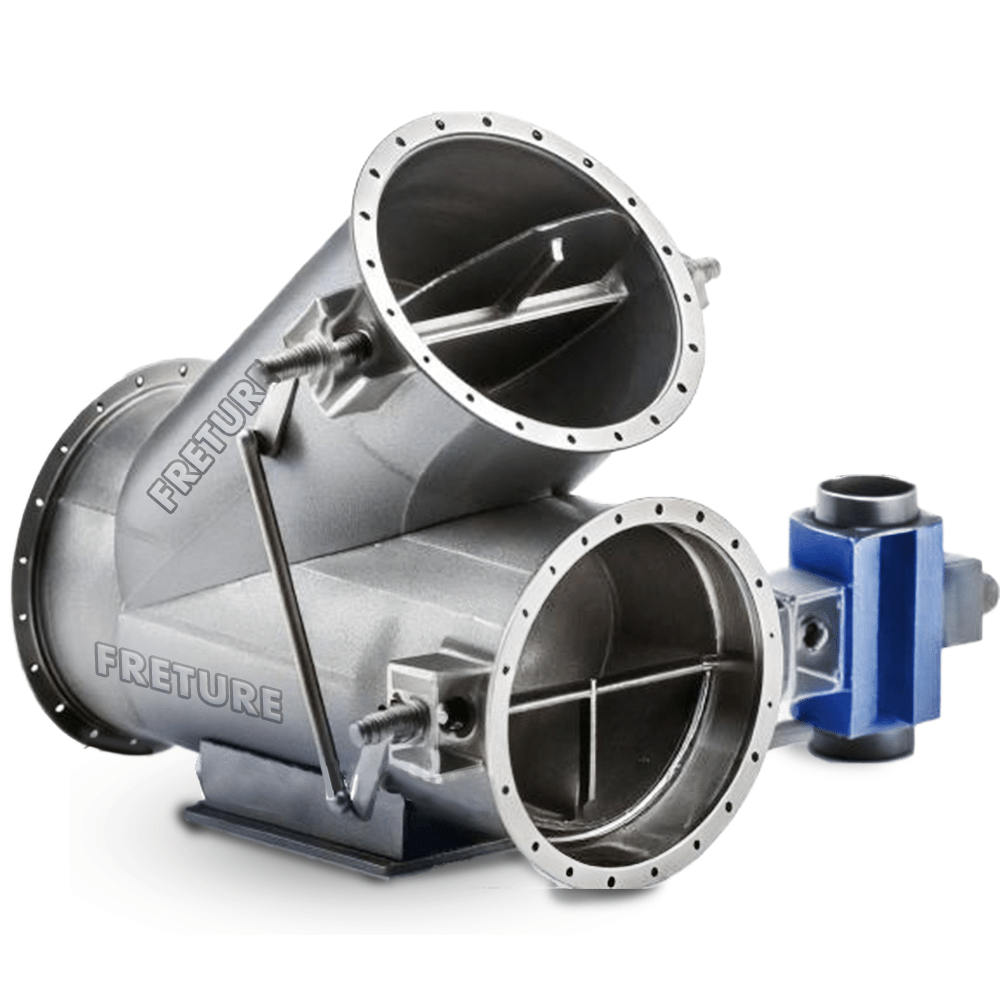

We are a leading Backdraft Damper manufacturer in Mumbai, India, specializing in providing reliable solutions to prevent reverse airflow in ventilation and exhaust systems. A Backdraft Damper is a vital component designed to allow air to flow in one direction while blocking any potential backflow in the opposite direction. These dampers play an essential role in protecting systems from reverse airflow, which can lead to contamination, equipment damage, or loss of energy efficiency.

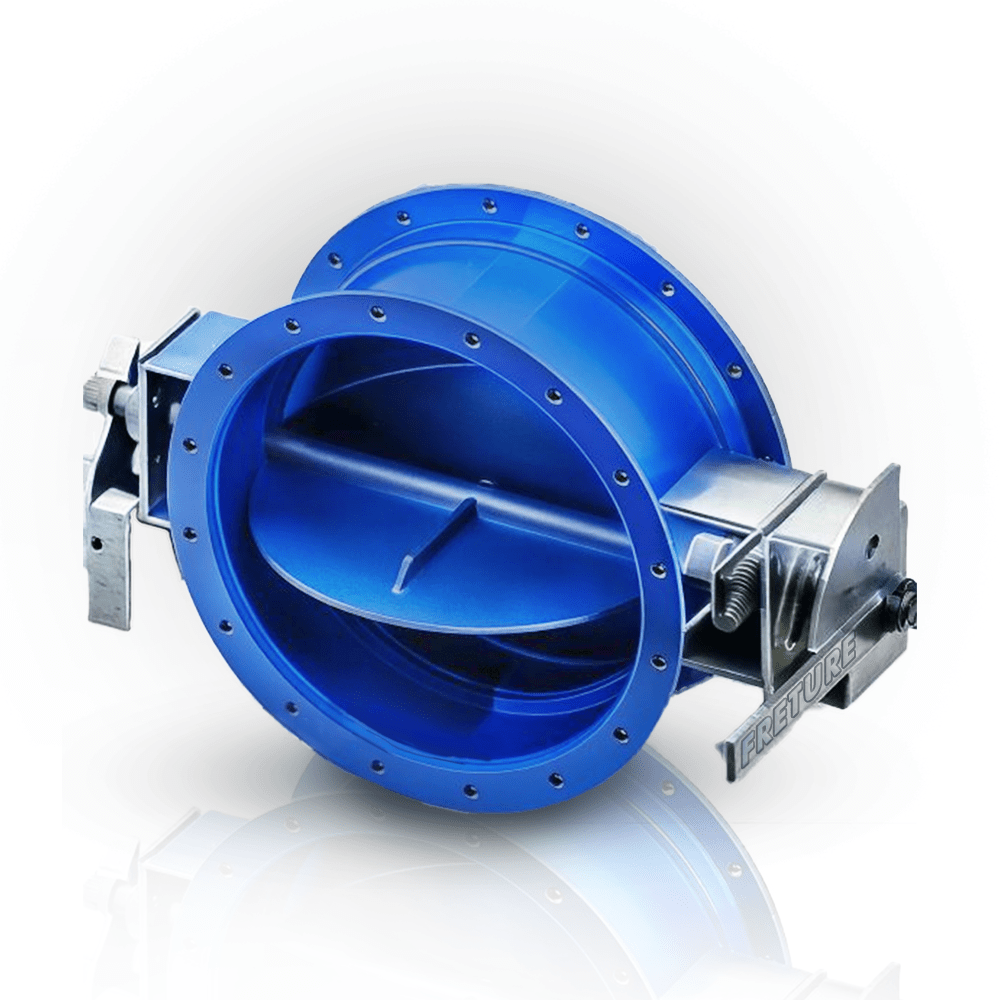

The damper operates with a set of hinged flaps or blades that automatically open to allow airflow in the intended direction and close when airflow reverses. This self-acting mechanism ensures the system remains protected at all times. Backdraft damper are widely used in HVAC systems, industrial exhaust systems, and fire/smoke control applications. Made from materials like stainless steel or galvanized steel, they are built to withstand challenging environments. These dampers are a key part of maintaining safety, system performance, and energy efficiency in both residential and industrial settings.

Specifications | Features |

|---|---|

Type: Backdraft Damper Sizes: 4" to 120" (Custom sizes available) Process Temperature: Up to 1500°F (Higher available with special materials) Configurations: Round, Square, Rectangular (Custom options available) Construction: Galvanized Steel, Stainless Steel, Aluminum (Other materials available) Shutoff: Up to 99% Seal Options: Rubber, Metal Seat, High-Temperature Seals Actuation: Spring-Loaded, Electric, Pneumatic (Failsafe available) Modulation: Passive (Automatic closure upon airflow reversal) Durability: Made from robust, corrosion-resistant materials for long-lasting use. Fire Safety Compliant: Helps prevent smoke and flame spread during fire incidents. Low Maintenance: Minimal upkeep due to simple, sturdy design. Flexible Operation: Opens/closes automatically with airflow direction. |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Backdraft Damper?

- How do these Damper work?

They use a spring-loaded or gravity-operated mechanism to automatically close when reverse airflow occurs, preventing backdrafts from entering the system.

- What are the common applications of these Damper?

These Damper are commonly used in HVAC systems, industrial exhaust systems, and fire protection systems to prevent reverse airflow and maintain system integrity.

- Can these damper be used in high-temperature environments?

Yes, they are available in materials and designs that can withstand temperatures up to 400°C, with special high-temperature variants available for extreme conditions.

- What materials are used in the construction of these Damper?

Backdraft Damper are typically made from materials like carbon steel, stainless steel (SS304, SS316), and aluminum, depending on the application’s requirements.

- Are the Damper fire-safe?

Yes, they are designed with fire-safe features, including flameproof seals and materials, to meet fire safety standards.

- What is the lifecycle of a Backdraft Damper?

The cycle life can reach up to 1 million cycles, depending on the operational conditions and the quality of materials used.

- Can the size of thes Damper be customized?

Yes, they are available in various sizes and can be customized based on the specific requirements of the system.

- What type of operation is available for these Damper?

They are available with manual, motorized, or pneumatic operation to suit different system needs and preferences.

- Do they need regular maintenance?

They require minimal maintenance due to their durable construction and high-quality seals, but regular inspection is recommended for optimal performance.

Industries where Backdraft Damper is Used

HVAC Industry

Power Generation

Oil and Gas Industry

Chemical Processing

Pharmaceutical Industry

Applications

- Air Handling Units (AHUs)– Prevents reverse air movement in ventilation systems.

- Exhaust Fans & Duct Systems – Ensures unidirectional airflow in commercial buildings.

- Fire & Smoke Control Systems– Helps maintain pressure zones in fire safety applications.

- Server Room Ventilation– Prevents overheating by ensuring proper airflow.

- Brewery CO₂ Ventilation– Prevents CO₂ buildup in brewing areas.

- LNG Facility Ventilation– Maintains controlled airflow in cryogenic conditions.

- Solvent Storage Room Ventilation– Ensures proper fume extraction.