These valves work by directing fluid flow between the inlet and two outlet ports, allowing for mixing or diverting of the flow as required by the process.

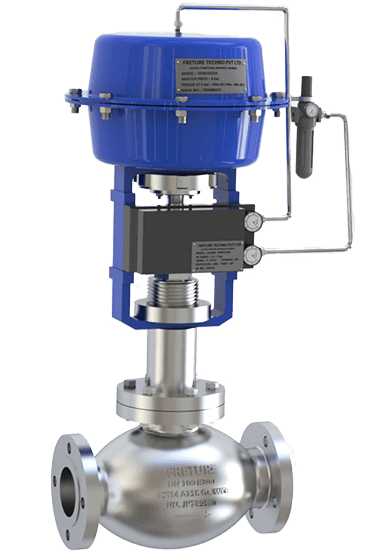

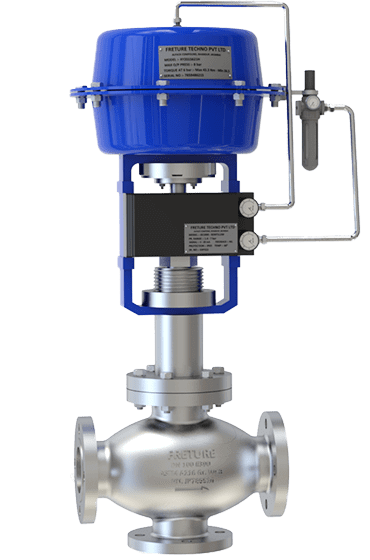

Globe Three Way Control Valve

FRETURE is a leading Globe 3 Way Control Valve manufacturers in Mumbai, India. Our valves adhere to international manufacturing standards, ensuring quality and reliability in every product.

A Globe 3 Way Valve is a type of process control valve that regulates the flow of fluid or gas in three different directions. It consists of a globe-shaped body with three ports: one inlet and two outlets. By adjusting the valve's position, users can control the flow between any two ports, allowing for versatile and precise flow management.

Applications of Globe 3 Way Valves

These control valves find applications in various industries where precise flow control is essential. They are commonly used in heating, ventilation, and air conditioning (HVAC) systems for mixing or diverting air flow. Additionally, they are employed in process industries such as chemical, petrochemical, and pharmaceutical for controlling the flow of liquids and gases in complex piping systems.

Why Choose FRETURE ?

FRETURE Globe 3 Way Control Valve offer several advantages:

Precision Engineering

Our valves are precision-engineered to provide accurate and reliable flow control, ensuring optimal performance in diverse applications.

Robust Construction

Built to withstand harsh operating conditions, our valves are constructed from high-quality materials, ensuring durability and longevity

Versatility

With their ability to control flow in three directions, our valves offer versatility, making them suitable for a wide range of applications.

Customization Options

We offer customization options to tailor valves to specific requirements, ensuring they meet the unique needs of each application.

Compliance with Standards

Our Globe 3 Way Valves comply with industry standards, ensuring they meet safety and performance requirements.

Expert Support

We provide expert technical support and guidance to help customers select the right valves for their applications and ensure smooth integration into their systems.

Choose FRETURE TECHNO for reliable, efficient, and high-performance 3 Way Globe Control Valves for your industrial applications.

Features of 3 way Control Valve:

- Outstanding valve capacity and rangeability for high-flow applications.

- Thoroughly designed and tested to guarantee optimal performance under challenging process conditions.

- Robust stem construction built for heavy-duty use

- Extensive selection of interchangeable trim sizes for versatility.

- Bellow seals provided for reliable stem sealing, ensuring a positive seal.

- Diverse range of actuators are available to meet various operational requirement

Description | Features |

|---|---|

Type : Globe Three Way Control End Connection : Flanged, Butt Weld, Screwed, and Socket Weld Size : 15NB - 450NB Class: 150# - 1500# Temperature Range : Standard up to 250 °C Normalizing (Finned) between 250°C to 500°C Extended cold service -20°C to -100°C Cryogenic -100°C to -250°C (Bellows seals) Body Materials: Carbon Steel, Chrome-moly Steel, Stainless Steel, Monel, Alloy 20, Hastelloy B/C, Duplex Stainless Steel, Aluminum Bronze, PP, PTFE, etc Design Std. : ASME B16-34, ANSI/FCI-70-2 Trim Design : Skirt Guided, Linear, Pressure Balance Trim Materials : Stainless Steel, Alloy20, Monel, Duplex Stainless Steel, 13% Chrome Steel, Hastelloy B/C, Stellite Face-to-Face : ISA S.75.03 up to 600# Seat Leakage: ANSI/FCI-70-2 Class III, IV, V and VI, Metal to Metal Seating Class IV, Metal to Soft Seating, Bubble tight (Zero Leakage) Actuator Type : Diaphragm, Piston, or Electric Accessories : Valve Positioner (Pneumatic, Electro-Pneumatic, Smart), Instruments, Limit Switches, Top or Side Mounted Handwheel, Limit Stops, Removable Blind Head |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- How does a Globe 3 Way Control Valve work?

- Are they safe?

Yes, Globe Three Way Control Valves are designed with safety features to ensure reliable operation and control over fluid flow in various industrial applications.

- What are the benefits?

Benefits include the ability to control multiple processes with a single valve, flexibility in system design, reduced piping complexity, and improved efficiency.

- Do I really need a Globe 3 Way Control Valve for my factory?

If your factory requires precise control over fluid flow in multiple directions, a 3 Way Globe Control Valve can be beneficial for process efficiency and flexibility.

- Are these valves capable of handling high pressures and temperatures?

Yes, these valves are capable of handling high pressures and temperatures commonly found in industrial processes.

- Can these valves be used for both on-off and throttling applications?

Yes, they can be used for both on-off and throttling applications, providing precise control over fluid flow rates.

- How do I maintain these Control Valve?

Regular maintenance includes inspection, cleaning, lubrication, and replacement of worn parts to ensure optimal performance and longevity.

- Are these Control Valves repairable?

Yes, most the Control Valves are designed to be repairable, allowing for easy replacement of worn or damaged components.

- How do I know which type of Control Valve is ideal for me?

Consult with a valve manufacturer or engineer to determine the ideal type based on factors such as fluid type, flow rate, pressure, temperature, and control requirements.

- Why is Freture the best place to buy Globe Three Way Control Valves from?

Freture is the best choice because of our precision engineering, high-quality materials, customization options, competitive pricing, comprehensive support, and commitment to customer satisfaction.

Industries where Globe Three Way Control Valve is used

Chemical Processing

HVAC

Petrochemical

Oil and Gas Industry

Pharmacutical Industry

Applications of Globe 3 Way Control Valve

- Mixing Services: Combines two fluid streams into a single output stream.

- Diverting Services: Splits one fluid stream into two separate output streams.

- Temperature Control: Regulates mixing of hot and cold fluids to maintain desired temperature.

- Hydronic Heating Systems: Controls the flow of water in heating systems for efficient temperature management.

- Chemical Processing: Manages the mixing and distribution of chemicals in industrial processes.