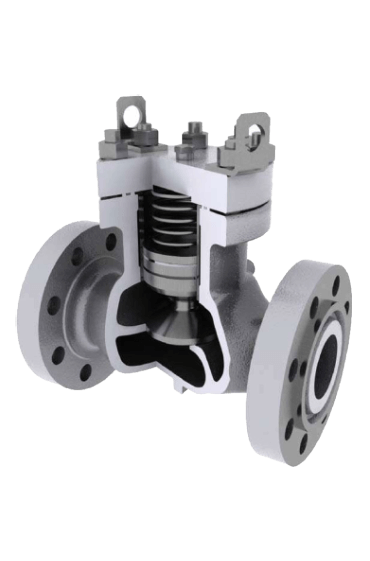

It is a type of check valve used to regulate the flow of fluids in a piping system. It allows flow in only one direction and prevents backflow.

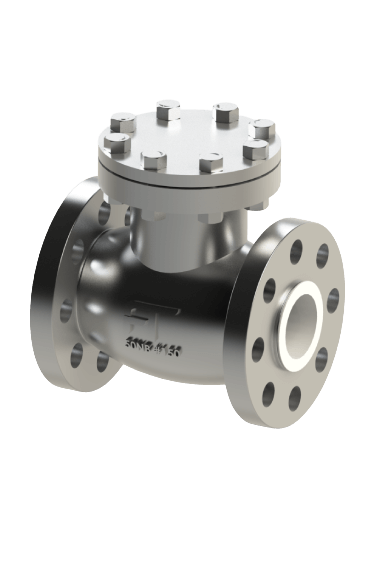

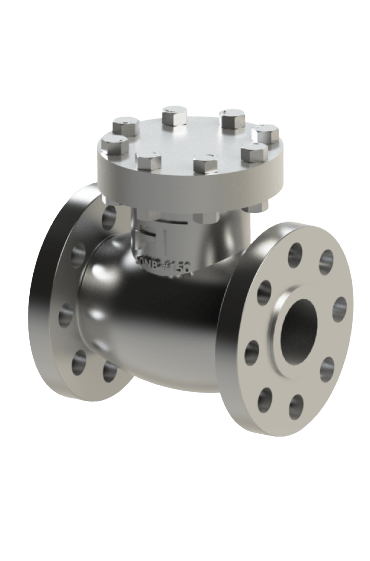

Swing Check Valve

One-way flow, guaranteed.

We are Swing Check Valve Manufacturers, Suppliers in Mumbai, India. The valve is a simple yet essential component of pipes, ensuring that liquid flows only in one direction. The valve body is hinged with a disc. When forward flow pushes against the disc, it swings open to allow smooth passage. As soon as the flow stops, the disc swings back onto a seat, preventing any backflow.

Freture's swing check valves are popular across multiple industries due to their low pressure drop and ease of maintenance. Swing Check Valve are used in various applications such as water and wastewater systems, HVAC systems, and petrochemical plants. Valve discs and seats can be designed to meet specific requirements, and some valves incorporate levers, weights, or springs to optimize performance.

Specifications | Features |

|---|---|

Type: Swing Check Valve End Connection: Flanged, Threaded, Socket Weld, Butt Weld (ASME B16.5 / B16.11 / B16.25 / ANSI 1.20.1) Size: 50NB - 600NB Pressure Rating: 150# - 2500# Temperature: -29°C to 425°C (-20°F to 800°F) Material: Cast Iron, Stainless Steel, Carbon Steel, Alloy Steel, etc. Design Standard: API 594, API 6D, ASME B16.34 Leakage Class: ANSI Class VI (Zero Leakage) Seat: Nitrile, EPDM, or Viton (metal-to-Metal, soft-seated) Safety: BS/EN, NACE, API 598 Rev 2009, API 607 Rev 2010 | Swing Disc Mechanism: Utilizes a hinged disc that swings open and close Efficiently. Low Pressure Drop: Minimizes pressure loss for efficient fluid flow. Unidirectional Flow: Allows flow in one direction while preventing backflow. Automatic Operation: Functions without the need for external control. Low Friction Operation: Minimizes friction for efficient flow. Pressure Rating: Capable of withstanding high-pressure environments. Long Service Life: Durable construction ensures a long operational lifespan. Corrosion Resistance: Offers excellent resistance to harsh environments. |

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a swing check valve?

- How does it work?

It operate using a hinged disc that swings freely to allow flow in one direction and closes to prevent backflow when the flow reverses.

- What are the main applications?

It is used in various industries such as water distribution systems, wastewater treatment plants, oil and gas pipelines, and HVAC systems.

- What are the benefits of using one?

Ensures unidirectional flow, prevents backflow, reduces pressure drop, minimizes water hammer effects, and requires minimal maintenance.

- What materials are used in their construction?

Cast iron, ductile iron, carbon steel, stainless steel, bronze, and various materials are used in Construction for Durability.

- How do I choose the right one for my application?

To Choose Right One for your application. Always,Consider factors such as valve size, pressure rating, temperature range, material compatibility, flow rate, and installation requirements.

- Can they be repaired?

Some components of swing check valves may be repairable or replaceable, depending on the extent of damage and the valve's design.

- What maintenance is required?

Generally, they require minimal maintenance. Regular inspection for any signs of wear, cleaning, and lubrication of moving parts are recommended to ensure continued reliable operation.

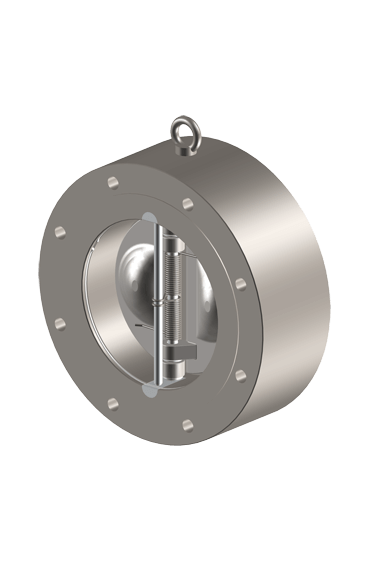

- Are they available in different designs?

They are available in various designs including flanged, wafer, and threaded connections, as well as different configurations such as horizontal and vertical installations for diffrent needs.

- Why is Freture the best place to buy from?

Freture offers a wide selection of high-quality swing check valves, manufactured to industry standards and backed by reliable customer support. With competitive pricing, fast delivery, and a commitment to customer satisfaction, Freture ensures a seamless purchasing experience for your valve needs.

Oil and Gas Industry

Water Treatment

Chemical Processing

HVAC Systems

Power Generation

Applications of Swing Check Valve

- Pipelines:Preventing backflow in pipelines and plumbing systems.

- Water Treatment: Maintaining flow direction in water treatment plants.

- HVAC: Regulating fluid flow in HVAC systems.

- Chemical processing: Controlling the direction of fluids in chemical processing plants.

- Oil And Gas: Ensuring the integrity of piping systems in oil and gas refineries.