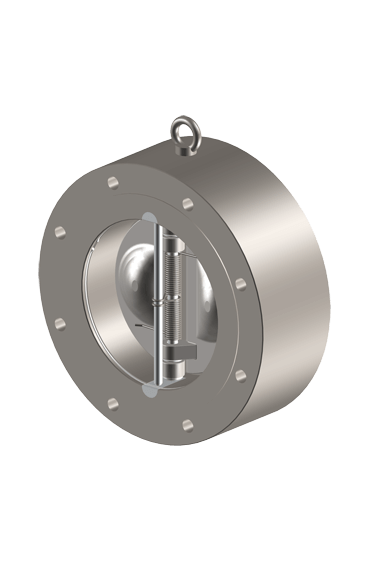

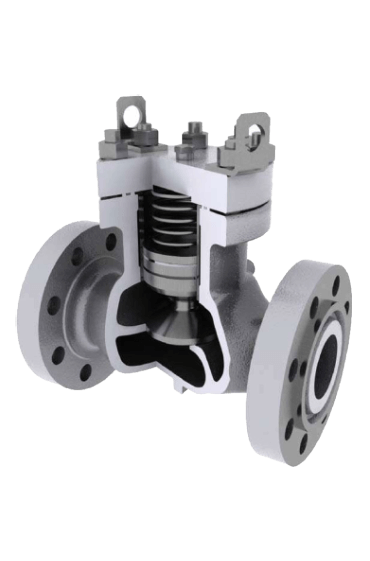

It is a type of check valve that employs a piston mechanism to prevents backflow an allow Fluids to flow only in one direction.

Piston Check Valve

Stop Backflow, Not Performance.

We are leading API 602 Forged Steel Piston Check Valve manufacturer in Mumbai, India. Unlike some check valves with swinging flappers, ensures smooth operation and minimal pressure loss in pipes. This automatic valve uses a guided piston to control flow direction. When fluid flows in the desired direction, the piston is lifted, allowing passage. If the flow tries to reverse, pressure forces the piston down to seal the valve.

This innovative design from Freture's Piston Check Valve minimizes resistance and pressure drop, even with frequent flow direction changes. Furthermore, it incorporates a spring mechanism, making it ideal for vertical installations and applications requiring additional closing force. The robust construction guarantees dependable performance for years to come.

The Valve is a critical component used to maintain unidirectional fluid flow in industrial systems. This valve features a unique piston mechanism that moves in response to the flow pressure, ensuring smooth operation and preventing backflow. Its precision engineering makes it ideal for maintaining system efficiency and protecting equipment.

Key Advantages

Reliable Performance

They are designed to offer consistent and dependable operation. Their ability to automatically prevent reverse flow ensures uninterrupted processes and safeguards critical system components.Enhanced Sealing

The piston mechanism provides a superior seal compared to conventional check valves. This ensures minimal leakage, contributing to energy efficiency and reduced maintenance needs.Durable Construction

These valves are built with robust materials to handle demanding conditions, including high pressure and temperature. Their sturdy design makes them a long-lasting solution for various industrial environments.Minimal Pressure Drop

The design of this valves minimizes flow resistance, ensuring a smooth and efficient flow of fluids with negligible pressure loss.Compact and Space-Saving Design

They are compact, making them ideal for installations where space is a constraint. Despite their small size, they deliver exceptional performance.Low Maintenance

With fewer moving parts and a durable design, they require minimal maintenance. This translates to reduced downtime and lower operational costs.

Why They Matter

They play a vital role in maintaining system integrity. By preventing backflow, they protect equipment, reduce the risk of contamination, and improve operational safety. Check Valve ability to perform reliably under challenging conditions makes them a preferred choice for industries worldwide.

Incorporating a piston check valve into your system ensures efficiency, longevity, and peace of mind in critical processes.

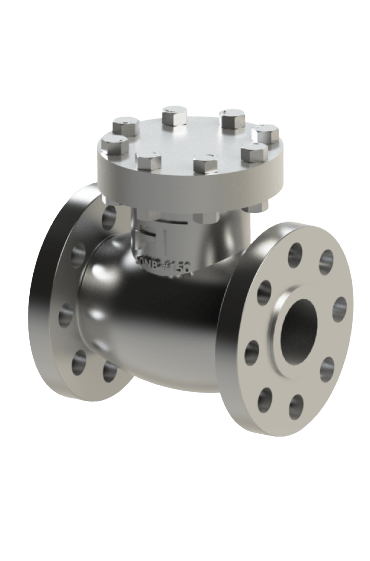

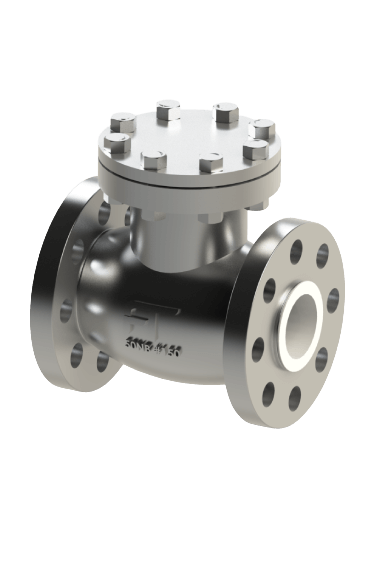

Specifications | Features |

|---|---|

Type: Piston Check Valve End Connection: Flanged, Threaded, Socket, Butt Weld (ASME B16.5 / B16.11 / B16.25 / ANSI 1.20.1) Size: 15NB - 600NB Class: 150# - 2500# Temperature: -20°C to 400°C (-4°F to 752°F) Material: Carbon Steel, Stainless Steel, Alloy Steel, etc. Design Standard: API 6D / API 602 / API 594 Leakage Rate: ANSI Class VI Seat: Nitrile, EPDM, or Viton (Metal-to-Metal, soft-seated) Safety: BS / EN, NACE, API 598 Rev 2009, ISO 5208, and API 607 Rev 2010 | Piston Mechanism: Utilizes a piston to control flow direction. Low Friction Operation: Smooth piston movement reduces friction for efficient flow. High Pressure Rating: Capable of withstanding high-pressure environments. Minimal Pressure Drop: Maintains system efficiency by minimizing pressure loss. Automatic Operation: No external operational need. Silent Operation: Operates quietly without causing noise disturbances. Ease of Maintenance: Designed for maintenance ease. Safety Features: Prevent accidents and protect from damage due to reverse flow. |

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Piston Check Valve?

- How do they work?

When fluid flows in the desired direction, the valve opens, and when there is reverse flow, the valve closes to prevent it.

- What are the main applications?

Commonly found in chemical plants, pharmaceuticals, and water treatment for corrosion resistance.

- What are the benefits of using one?

The benefits include corrosion resistance, chemical compatibility, high pressure rating, temperature versatility, minimal maintenance requirements, and reliable operation.

- What materials are used in their construction?

Constructed with robust materials like cast iron or stainless steel, lined with PFA, FEP, PVDF, or ETFE to withstand harsh chemicals and demanding conditions.

- How do I choose the right one for my application?

To choose Right valve, Consider factors such as pressure rating, temperature range, and size, ensuring compliance with industry standards and compatibility with your specific needs.

- Can they be repaired?

Yes! Most of components are easy to replace and repairable,

- What maintenance is required?

They Are Designed for low maintenance operation. Just Little Regular inspections and cleaning are recommended to ensure optimal performance and longevity.

- Are they available in different designs?

Yes, it is one of the most versatile Check valve in terms of designs and sizes. It is available in straight-through, angle, and oblique configurations,types to suit different installation requirements.

- Why is Freture the best place to buy from?

Freture offers a comprehensive selection of high-quality piston check valves, manufactured to industry standards and backed by reliable customer support. With competitive pricing, fast delivery, and a commitment to customer satisfaction, Freture ensures a smooth and hassle-free purchasing experience for your valve needs.

Industries where Piston Check Valve is Used

Oil and Gas Industry

Petrochemical Industry

Power Generation Industry

Water Treatment

Pharmaceutical Industry

Applications of Piston Check Valve

- Preventing Backflow in Industries: Industries such as oil and gas, petrochemical, and water treatment benefit from preventing backflow in pipelines.

- One-Way Flow Refinery Processes: Refinery processes and chemical plants rely on these valves to ensure unidirectional flow of fluids.

- Power Generation: It maintain system efficiency by preventing reverse flow in power generation applications.

- Safeguarding Pumping Systems: Various industrial processes are safeguarded from equipment damage due to backflow by these valves.

- Flow Control in HVAC Systems: HVAC systems and compressed air applications rely on these valves for reliable flow control.