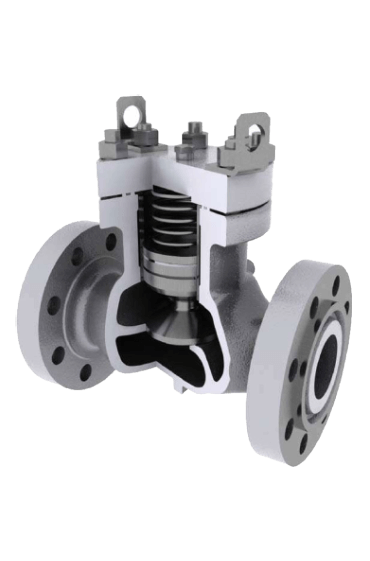

A lined check valve is a type of check valve designed with a lining material such as PTFE (polytetrafluoroethylene) to provide excellent corrosion resistance. It allows fluid to flow in one direction while preventing backflow.

PTFE / PFA Lined Check Valve

Prevent Backflow, Ensure Efficiency: PTFE Lined Check Valve

We are leading FEP, PVDF, PFA, PTFE Lined Check Valve Manufacturer in Mumbai, India. A lined check valve is a type of check valve that features an inner lining made of corrosion-resistant materials such as PTFE (polytetrafluoroethylene), FEP (fluorinated ethylene propylene), PFA (perfluoroalkoxy), or PVDF (polyvinylidene fluoride). This lining serves to protect the valve body from the corrosive effects of the fluid flowing through it.

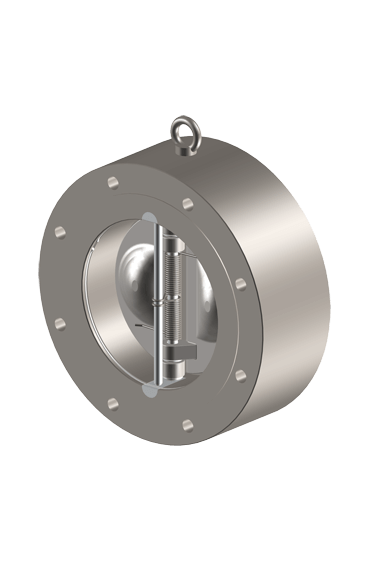

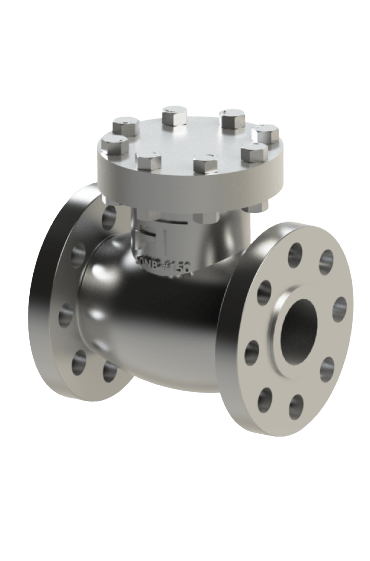

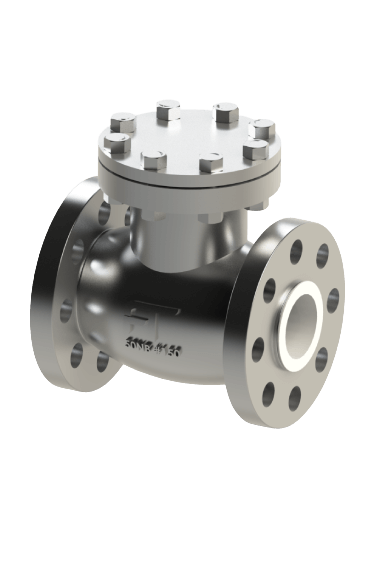

Freture's PTFE Lined check valves are predominantly used in industries such as the chemical processing, pharmaceuticals, and food and beverage, owing to their high-quality lining materials. They are ideally suited for applications where the handled fluid is highly corrosive or abrasive. These valves typically come in two main designs: lined wafer check valves and lined ball check valves. Wafer check valves are compact and cost-effective, while ball check valves offer lower pressure drop.

PFA Lined Check Valve – Superior Corrosion Resistance & Backflow Prevention

The PFA Lined Check Valve is engineered for optimal performance in highly corrosive and high-purity applications. Featuring a durable metal body with a seamless PFA lining, it ensures exceptional chemical resistance, leak-proof operation, and extended service life. The valve’s swing or ball check mechanism prevents backflow, making it ideal for industries like chemical processing, pharmaceuticals, and water treatment.

Designed for high-temperature and aggressive media, it meets ANSI, DIN, and JIS standards, ensuring global compatibility. With low maintenance and reliable sealing, it enhances system efficiency and safety.

Optimize your fluid control with a premium PFA Lined Check Valve. Contact us today for specifications and pricing!

Specifications | Features |

|---|---|

Type: PTFE / PFA Lined Check Valve End Connection: Flanged ( ASME B16.5 ) Size: 15NB - 600NB Class: 150# - 2500# Temperature: -20°C to 200°C (-4°F to 392°F) Body Material: Ductile Iron, Stainless Steel, or Carbon Steel Design Standard: API 6D / API 602 / API 594 Lining Material: PTFE, PFA, FEP, PVDF Seat: Nitrile, EPDM, or Viton (metal-to-Metal, soft-seated) Safety: BS / EN, NACE, API 598, ISO 5208 and API 607 Rev 2010 | Compact Design: Slim and lightweight, saving space. Low Pressure Drop: Minimizes pressure loss for efficient fluid flow. Silent Operation: Operates quietly without causing noise disturbances. Corrosion Resistance: Lined with materials like PFA, FEP, PVDF, or ETFE to resist corrosion. Low Friction: Smooth lining reduces friction for efficient flow. Pressure Drop Reduction: Minimizes pressure drop to maintain system efficiency. Easy Installation: Designed for straightforward installation between flanges. Chemical Compatibility: Resistant to various chemicals and aggressive substances. |

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a PTFE lined check valve?

- What are the advantages of using it?

Lined check valves offer exceptional corrosion resistance, making them suitable for handling aggressive and corrosive fluids. They also provide minimal to zero leakage, ensuring efficient and safe operation.

- What lining materials are commonly used in lined check valves?

Most commonly used lining materials for for its outstanding chemical resistance are PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxy), PVDF (Polyvinylidene Fluoride), and FEP (Fluorinated Ethylene Propylene).

- What types of fluids are compatible with it?

From corrosive fluids to acids & bases, they are compatible with any Aggressive Chemical Used in chemical processing, pharmaceuticals, petrochemicals, and water treatment industries.

- How does the lining material enhance the performance of a check valve?

The lining material acts as a protective barrier, preventing the corrosive fluid from coming into contact with the valve body. This significantly extends the valve's service life and ensures reliable performance in corrosive environments.

- Are lined check valves suitable for high-pressure applications?

Absolutely! They are perfect for high-pressure applications, especially when dealing with aggressive chemicals.

- How Much Temperature Can It Bear?

They can handle it all, from a chilly -20°C to a scorching 150°C, making them perfect for a wide range of temperature conditions!

- Can lined check valves be installed in different orientations?

Yes, lined check valves can be installed in horizontal, vertical, or angled orientations without affecting their performance. However, it's essential to follow the manufacturer's recommendations for proper installation.

- How often do these valves require maintenance?

They, require minimal maintenance due to their corrosion-resistant properties. Regular visual inspections are recommended to ensure the integrity of the lining material and the overall condition of the valve.

- What industry standards do lined check valves comply with?

Typically, they comply with industry standards such as API 598, ANSI B16.34, API 594, and ASME B16.10, ensuring quality, performance, and safety in various industrial applications.

Industries where (PTFE / FEP / PFA) Lined Check Valve is Used

Chemical Processing

Petrochemical Industry

Pharmaceutical Industry

Water Treatment

Power Generation

Applications of Lined (PTFE / FEP / PFA) Check Valve

- Chemical Processing: Prevents backflow of corrosive chemicals in chemical processing.

- Petrochemical Industry: Controls flow of hydrocarbons and corrosive fluids.

- Water Treatment: Ensures purity of treated water by preventing backflow.

- Pharmaceutical Industry: Maintains integrity of pharmaceutical products by preventing contamination.

- Food and Beverage Industry: Prevents backflow and contamination of food and beverages.