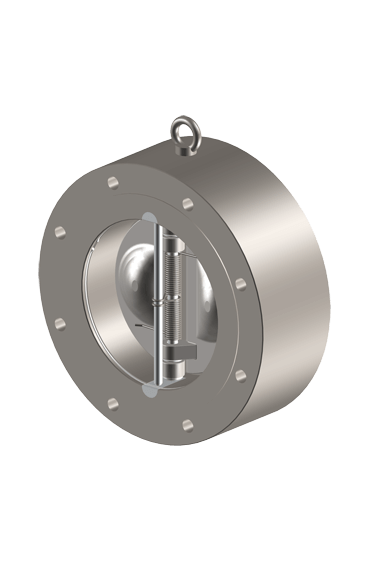

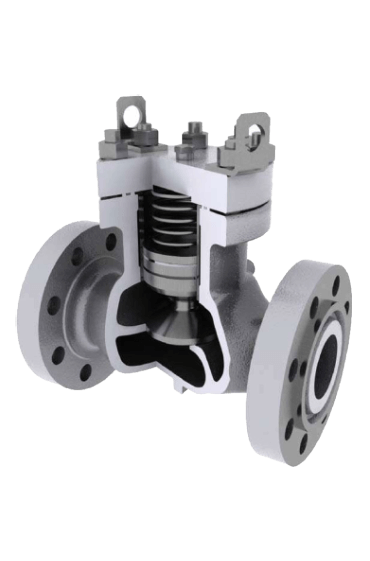

It is a type of check valve where the disc, often referred to as a lift, moves up and down within the valve body to allow or prevent flow. It is designed to automatically prevent backflow in a piping system.

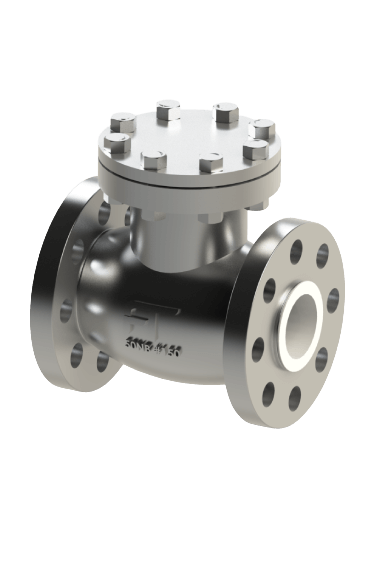

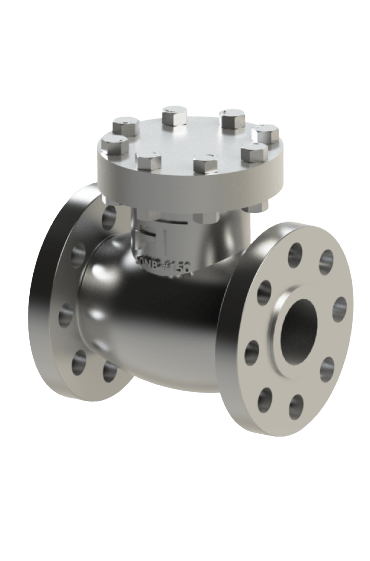

Lift Check Valve

Double the Protection: Valves for Leak-Free Lifting.

As a lift check valve manufacturers in Mumbai, India. Freture offers high-quality lift check valves, also known as non-return valves (NRVs). These valves function as one-way doors by preventing backflow through a disc or ball lodged within them. Fluid pressure pushes the disc or ball upwards, enabling flow in the desired direction. When the flow stops or reverses direction, a spring or the weight of the disc itself pushes it back down onto the seating surface, blocking the backflow.

Typically, this valves are used in high-flow or turbulent systems and can be installed horizontally or vertically. In situations where smaller diameters are needed, these valves are preferred over swing check valves. They are suitable for water, gas, and steam systems, as well as for various other applications.

Specifications | Features |

|---|---|

Type: Lift Check Valve End Connection: Buttweld, Flanged, Threaded (ASME B16.5 / B16.11 / B16.25 / ANSI 1.20.1) Size Range: 15NB - 600NB Class: 150# to 2500# Temperature Range: -29°C to 538°C (-20°F to 1000°F) Body Material: Carbon Steel, Stainless Steel, Alloy Steel Design Standard: API 6D / API 602 / API 594 Compliance: ASME, API, and DIN standards Seat: Metal-to-Metal, soft-seated (PTFE, EPDM) Safety: BS / EN, NACE, API 598 Rev 2009, API 607 Rev 2010 | Non-return Function: Prevents backflow in the system. Automatic Operation: Operates automatically without external control. Durable Construction: Made from high-quality materials for long service life. Corrosion Resistance: Suitable for various applications including corrosive environments. Compact Design: Space-saving and easy to install. High Flow Capacity: Optimized for maximum flow efficiency. Noise Reduction: Silent operation with anti-slam design. Leakage Prevention: Designed to prevent leakage, meeting standards like API 598. |

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Lift Check Valve?

- How does it work?

The valve operates automatically, allowing flow in one direction. When the fluid pressure drops or reverses, the disc is forced down onto the seat, stopping reverse flow.

- What are the typical applications of it?

These valves are commonly used in applications such as water, steam, air, gas, and oil systems to prevent backflow and protect pumps, compressors, and other equipment.

- What materials are used in the construction of these Valves?

These valves are typically constructed from materials such as carbon steel, stainless steel, alloy steel, and sometimes bronze, depending on the application and fluid type.

- What are the advantages of using it?

Advantages include a simple design with few moving parts, low maintenance, reliable sealing, and suitability for high-pressure and high-temperature applications.

- How do you select the right Valve for an application?

Selection should be based on factors such as the size and pressure rating of the system, the temperature of the fluid, the type of fluid, and the required end connections (flanged, threaded, or butt-weld)

- Can it be used in horizontal and vertical installations?

Yes,It can be installed both horizontally and vertically, provided the flow direction is considered, and the valve is properly supported.

- What maintenance is required for it?

Regular inspection is recommended to ensure the valve disc and seat are free from debris and wear. Periodic testing and cleaning may be required to maintain optimal performance.

- What standards and certifications apply to these valves?

Typically comply with standards such as API 598 for testing, ASME B16.34 for valve design, and various other international standards depending on the specific application.

- How can I ensure the longevity and reliability these Valve?

To ensure longevity, select a valve made from appropriate materials for the fluid and operating conditions, follow manufacturer guidelines for installation and maintenance, and regularly inspect and test the valve as part of a routine maintenance schedule.

Industries where Lift Check Valve is Used

Oil and Gas Industry

Petrochemical Industries

Water Treatment

Power Generation

Pharmaceutical Industry

Applications of Lift Check Valve

- Prevent Backflow in Pipelines: Prevent backflow in pipelines.

- Protect Pumps and Compressors: Protect pumps and compressors.

- Essential in Steam Systems: Maintains efficient and safe steam system operation.

- Ensure Water Distribution Network Safety: Keeps water supply systems safe and contamination-free.

- Maintain Hydraulic System Integrity: Preserves the proper functioning and efficiency of hydraulic systems.