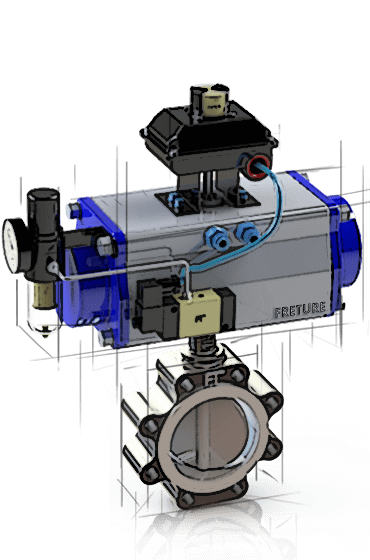

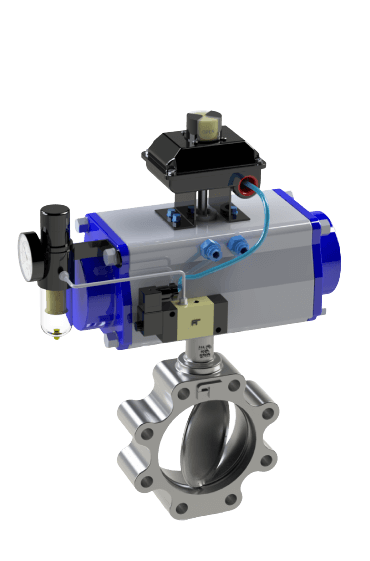

A single offset butterfly valve is a type of valve used to control the flow of fluids. It has one offset, meaning the disc is slightly off the centerline of the valve seat, which helps reduce friction during operation.

Single Offset Butterfly Valve

The valve ensures reliable, low-friction performance, versatile materials, and flexible control for industrial applications.

Freture Techno is a leading Single Offset Butterfly Valve manufacturer in Mumbai, India. It is a type of valve that uses a disc with a hole in the center to control the flow of fluid. The disc is rotated to open or close the valve. Single Offset Butterfly Valves are made from a single piece of metal, which makes them strong and durable. They are also resistant to corrosion, making them ideal for use in harsh environments.

Why Choose Feature Techno?

- Quality Assurance: Our valves are built to last and meet the highest industry standards.

- Cost-Effective: Competitive pricing without compromising on quality.

- Customization: Tailor-made solutions to meet your specific needs.

- Expert Support: Our team of experts is ready to assist you at every step.

- Proven Experience: Trust in our years of expertise in fluid control technology.

Upgrade your fluid control systems with Feature Techno's Single Offset Butterfly Valves. Contact us today and experience the difference in precision, reliability, and performance. Your satisfaction is our priority!

Specifications | Features |

|---|---|

Type: Signle Offset Butter Fly Valve End Connection: Flange (B16.5) / Lug Type / Wafer Type Size: 15 NB - 600 NB Class: 150# - 600# Temperature Range: -190° C to 350 ° C MOC: Carbon Steel / Stainless Steel / Alloy Design Standard: API 609 / EN 593 / MSS SP 67 / ISO 5752 Seat: Soft Seat- Nitrile Rubber, EPDM, Viton / Metal Seat Face to Face: API 609 CAT A / MSS SP-67 (Narrow Body), ISO 5752 (Short) Operation: Manual / Actuator / Gear Safety : NACE, BS/EN 10204-3.1 REV 2019, API 598 Rev 2009, API 607 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Single Offset Butterfly Valve?

- How does it work?

The valve operates by rotating a disc, which is mounted on a shaft. When the disc is turned, it aligns with the flow to allow fluid to pass or is perpendicular to the flow to block it.

- What are the main applications ?

These valves are commonly used in water treatment plants, HVAC systems, fire protection systems, and various industrial applications where reliable flow control is needed.

- What are the benefits of using one?

Advantages include low friction operation, longer valve life, quick operation, and compact design. They are also cost-effective and provide a good seal with less wear on the seat.

- What materials are used in their construction?

They are typically made from materials such as stainless steel, cast iron, ductile iron, and various high-performance alloys, depending on the application's requirements.

- How do I choose the right one for my application?

Consider factors such as the type of fluid, operating pressure and temperature, required flow control precision, material compatibility, and the specific application's environmental conditions. Consulting with a valve specialist can also help in making the right choice.

- Can they be repaired?

Yes, single offset butterfly valves can be repaired by inspecting for damage, disassembling, cleaning, replacing worn parts, reassembling, and testing for proper operation. Regular maintenance helps extend their lifespan.

- What maintenance is required?

Regular maintenance includes inspecting the valve for leaks, checking the disc and seat for wear, ensuring the shaft and seals are in good condition, and lubricating moving parts if necessary.

- Are they available in different designs?

Yes, single offset butterfly valves are available in various designs to suit different applications and specifications.

- Why is Freture the best place to buy from?

Freture is the best place to buy from because they offer top-quality products, great prices, and excellent customer service. We provide expert advice, fast delivery, and reliable support, ensuring your satisfaction every time.

Industries where Single-offset Butterfly Valve is Used

Water Treatment

HVAC Systems

Oil and Gas

Chemical Processing

Power Generation

Applications of Single Offset Butterfly Valve:

- Flow Control: Regulating the flow of liquids and gases in pipelines.

- Isolation: Providing shut-off capabilities in various systems to isolate sections for maintenance or emergency purposes.

- Throttling: Managing fluid flow rates in process systems by adjusting the valve position.

- HVAC Systems: Controlling air and water flow in heating, ventilation, and air conditioning systems.

- Water Treatment Plants: Used in filtration, chemical dosing, and distribution processes to manage water flow efficiently.