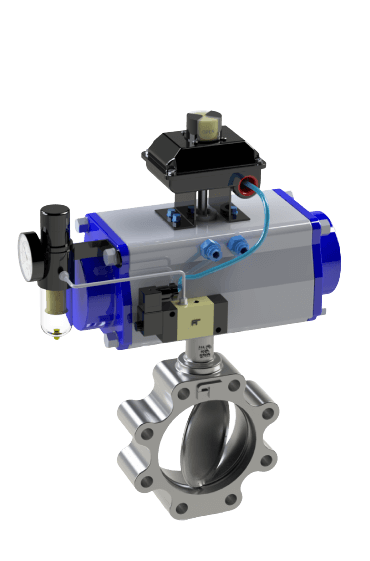

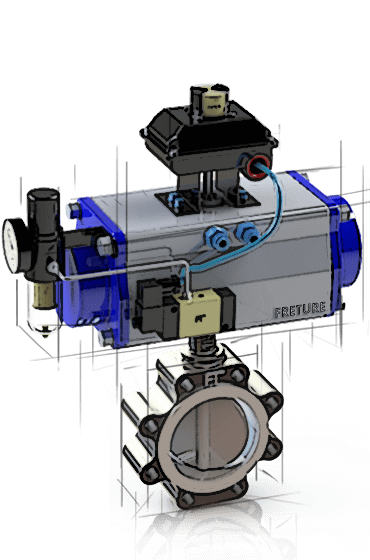

A Teflon Lined Butterfly Valve is a type of valve equipped with a lining material such as PTFE, PFA, or FEP on its internal surfaces to provide resistance against corrosion and chemical attack.

PTFE Butterfly Valve

Lined Butterfly valves are well renowned for their corrosion-resistant construction.

Freture Techno Pvt. Ltd is a leading PTFE Lined Butterfly Valve manufacturer in Mumbai, India. We offer a wide range of Butterfly Valves in a variety of sizes, materials, and finishes. Butterfly valves are made to the highest standards and are backed by our comprehensive warranty.

What are Lined Butterfly Valves?

They are a type of butterfly valve that has a lining on the inside of the valve body. The lining is typically made of a material that is resistant to corrosion, such as PTFE, PFA, or FEP. The Valves are used in applications where the fluid being conveyed is corrosive or abrasive.

How do Lined Butterfly Valves Work?

PTFE Lined Butterfly Valves work in the same way as standard butterfly valves. The valve has a disc that is attached to a stem. When the stem is rotated, the disc rotates and opens or closes the valve. The lining on the inside of the valve body helps to protect the valve from corrosive or abrasive fluid.

Features of PFA, FEP, PVDF and PTFE Butterfly Valves

Corrosion resistance: The valves are resistant to corrosion because of the lining on the inside of the valve body. This makes them ideal for use in applications where the fluid being conveyed is corrosive.

Abrasion resistance: They are also resistant to abrasion because of the lining on the inside of the valve body. This makes them ideal for use in applications where the fluid being conveyed is abrasive.

Easy to operate: They are easy to operate. They can be opened and closed quickly and easily, even under pressure.

Wide range of sizes and materials: They are available in a wide range of sizes and materials. This allows you to choose the right valve for your specific application.

Applications of PTFE Butterfly Valves

Teflon Lined Butterfly valves are used in a variety of applications, including:

Chemical processing: These valves are used in the chemical processing industry to control the flow of corrosive chemicals.

Oil and gas: These Butterfly valves are used in the oil and gas industry to control the flow of corrosive fluids.

Water treatment: These Butterfly valves are used in the water treatment industry to control the flow of corrosive water.

Power generation: They are used in the power generation industry to control the flow of corrosive fluids.

HVAC: They are used in the HVAC industry to control the flow of corrosive fluids.

If you are looking for a high-quality, durable, and reliable PTFE Butterfly Valve, then Freture Techno Pvt. Ltd is the perfect choice for you. Contact us today to learn more about Butterfly valves and how we can help you meet your needs.

PTFE Butterfly Valves are a versatile and reliable type of valve that can be used in a variety of applications. They are resistant to corrosion, abrasion, and easy to operate. If you are looking for a high-quality valve for your next project, then a PTFE Butterfly valve is a great option.

Specifications | Features |

|---|---|

Type: PTFE Butterfly Valve End Connection: Flanged, Wafer ( ASME B16.5 ) Size: Range 2" (50mm) to 24" (600mm) Class: 150# - 600# Temperature Range: -20°C to 200°C Body Material: Carbon Steel, Stainless Steel, Ductile Iron Lining Material: PTFE, PFA, FEP, PVDF, Polypropylene, or other suitable materials Disc Material: Stainless Steel, Ductile Iron, Aluminum Bronze Design Standard: API 609, EN 593 Face to Face Dimension API 609, EN 558 Actuation: Manual / Actuator / Gear Safety Standards: NACE MR0175, API 598, API 607, ISO 10497 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Teflon Lined Butterfly Valve?

- How does it work?

It operates by rotating a disc within the flow path to control the flow of fluid. The lining material ensures a smooth and corrosion-resistant surface for fluid contact, while the disc regulates flow by either blocking or allowing passage through the valve.

- What are the main applications?

Lined Butterfly Valves are commonly used in industries such as chemical processing, petrochemical, pharmaceutical, water treatment, and pulp and paper for handling corrosive and abrasive fluids.

- What are the benefits of using one?

The benefits include excellent corrosion resistance, chemical compatibility, reliable sealing, low maintenance, and suitability for a wide range of applications.

- What materials are used in their construction?

Lined Butterfly Valves are typically constructed with a metal body and a lining material such as PTFE, PFA, FEP, PVDF, or polypropylene to provide corrosion resistance.

- How do I choose the right one for my application?

Consider factors such as the type of fluid, temperature range, pressure rating, valve size, end connections, and compatibility with specific application requirements to select the appropriate lined butterfly valve.

- Can they be repaired?

Yes, lined butterfly valves can be repaired by replacing damaged components such as the lining material, disc, or seals as needed.

- What maintenance is required?

Regular maintenance includes inspection, cleaning, and lubrication of moving parts to ensure smooth operation and prevent corrosion or damage to the lining material.

- Are they available in different designs?

Yes, lined butterfly valves are available in various designs, including wafer, lug, and flanged configurations, as well as different lining materials and actuation options to suit different application needs.

- Why is Freture the best place to buy from?

Freture is the preferred choice for purchasing lined butterfly valves due to our commitment to quality, extensive industry experience, and dedication to customer satisfaction. We offer a wide range of high-quality valves, expert technical support, competitive pricing, and tailored solutions to meet your specific needs.

Industries where PTFE Butterfly Valves is Used

Chemical Processing

Petrochemical Industry

Pharmaceutical Industry

Water Treatment Industry

Pulp and Paper Industry

Application of PTFE Butterfly Valve

Chemical Processing: Reliable flow control of corrosive acids.

Petrochemical Industry: Handling aggressive fluids.

Pharmaceutical Industry: Prevents contamination.

Water Treatment: Regulates corrosive chemicals.

Pulp and Paper Industry: Manages corrosive chemicals and slurries.