A concentric design butterfly valve is a type of quarter-turn valve used to control flow within pipelines. It features a disk in the shape of a cylinder mounted on a rotating shaft.

Concentric Design Butterfly Valve

The concentric butterfly valve is a kind of butterfly valve that is often used.

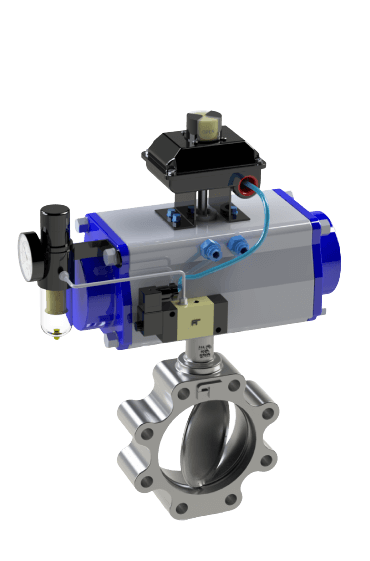

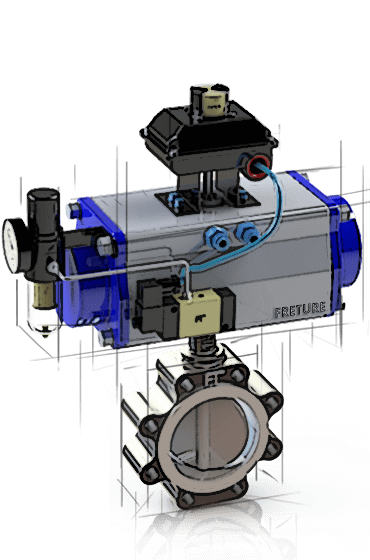

Freture Techno Pvt. Ltd is a leading Concentric Butterfly valve manufacturer in Mumbai, India. This design produces a cam-like motion, allowing the disc to lift off the seat during opening, which minimizes wear on both the seat and disc. We offer a wide range of Butterfly valves in a variety of sizes, materials, and finishes. These Butterfly valves are made to the highest standards and are backed by our comprehensive warranty.

These Butterfly valve is a type of valve that uses a rotating disk to control the flow of fluid. It is also known as zero-offset Butterfly valves or resilient-seated Butterfly valves. The disk is centered in the valve body, which allows for a more compact design and easier installation. Butterfly valves are available in a variety of sizes and materials, making them ideal for a wide range of applications.

How Concentric Design Butterfly Valves Work?

These Butterfly valves work by rotating a disk that is centered in the valve body. When the disk is aligned with the flow of fluid, the valve is open. When the disk is rotated 90 degrees, the valve is closed. These Butterfly valves can be operated manually or with a pneumatic or electric actuator.

Types of Concentric Butterfly Valves

Concentric Butterfly valves come in various designs based on body configuration, connection type, and operational requirements. The Wafer type Butterfly valve is the most common and is designed to fit between two pipeline flanges, offering a lightweight and cost-effective solution for low to medium-pressure applications. The Lug Type Butterfly valve features threaded inserts (lugs) that allow bolting to pipeline flanges, enabling the removal of one side of the pipeline without disturbing the other. This design is ideal for dead-end service and facilitates easier maintenance. Another widely used type is the flanged butterfly valve, which has integral flanges for direct connection to pipeline flanges, ensuring a more robust installation with higher pressure-handling capabilities.

For applications requiring enhanced sealing, the rubber-lined butterfly valve comes with an elastomer lining, such as EPDM, NBR, or Viton, ensuring excellent sealing performance for water, wastewater, and non-corrosive fluids. On the other hand, the PTFE Lined Butterfly Valve is specifically designed for aggressive chemical applications, using a Teflon lining to provide superior corrosion resistance and prevent contamination. In high-temperature and high-pressure environments, metal-seated butterfly valves are preferred, as they use metal-to-metal contact for sealing, making them suitable for steam, gas, and industrial fluid control.

Automation has also led to the development of pneumatic actuated Butterfly valves, which utilize pneumatic actuators for quick and efficient operation in automated systems, reducing manual effort. Similarly, electric actuated butterfly valves provide precise regulation through an electric actuator, making them ideal for industries requiring automation and remote monitoring, such as HVAC, water treatment, and chemical processing.

Why Freture Techno?

If you are looking for a high-quality, durable, and reliable Concentric Design Butterfly valve, then Freture Techno Pvt. Ltd is the perfect choice for you. Contact us today to learn more about Butterfly valves and how we can help you meet your needs.

Specifications | Features |

|---|---|

Type: Concentric Design Butterfly Valve End Connection: Flange (B16.5) / Lug Type / Wafer Type Size: 15 NB - 600 NB Class: 150# - 600# Design Standard: EN 593 (BS 5155), API 609, MSS SP-67 Temperature Range: -29°C to +200°C (-20°F to +392°F) MOC: Carbon Steel / Stainless Steel / Alloy Seat: Soft Seat- Nitrile Rubber, EPDM, Viton / Metal Seat Face to Face: API 609 CAT A / MSS SP-67 (Narrow Body), ISO 5752 (Short) Operation: Manual / Actuator / Gear Safety Standards: BS/EN 10204-3.1 REV 2019, API 598 Rev 2009 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Concentric Design Butterfly Valve?

- How does it work?

The valve operates by rotating the disk a quarter turn to either allow or restrict flow. When fully open, the disk aligns with the flow direction, minimizing turbulence and pressure drop.

- What are the main applications?

They are commonly used in industries such as water treatment, HVAC, chemical processing, and food & beverage for regulating or isolating flow in pipelines.

- What are the benefits of using one?

Benefits include reliable flow control, compact design, low pressure drop, ease of operation, and suitability for large-scale applications.

- What materials are used in their construction?

Materials vary but often include stainless steel, carbon steel, ductile iron, and various types of polymers for the valve body and disk, tailored to specific application requirements.

- How do I choose the right one for my application?

Consider factors such as pressure ratings, temperature range, media compatibility, valve size, and operational environment. Consulting with a valve specialist is advisable for optimal selection.

- Can they be repaired?

Yes, depending on the valve design and manufacturer, many butterfly valves can be repaired or refurbished to extend their service life.

- What maintenance is required?

Regular maintenance typically involves inspection, lubrication of moving parts, checking for leaks, and replacing seals or components as needed to ensure reliable performance.

- Are they available in different designs?

Yes, they come in various designs including lug, wafer, and double-flanged types to accommodate different piping systems and installation requirements.

- Why is Freture the best place to buy from?

Freture stands out due to its extensive range of high-quality valves, expertise in valve solutions, competitive pricing, and excellent customer service, ensuring satisfaction and reliability in every purchase.

Industries where Concentric Design Butterfly Valve is Used

HVAC Industry

Wastewater Treatment

Chemical Processing

Oil and Gas

Pulp and Paper

Applications

- HVAC Systems: For flow control in heating and cooling systems.

- Water Treatment Plants: Regulating water flow efficiently.

- Chemical Processing: Handling various chemicals in manufacturing.

- Oil and Gas Industries: Controlling flow in refineries and pipelines.

- Pulp and Paper Manufacturing: Managing flow in paper mills.