A Bellow Seal Globe Valve is a control valve with a bellows seal that prevents fluid leaks through the stem, ideal for high purity and hazardous applications.

Bellow Sealed Globe Valve

Leak-free stem sealing for critical fluid applications.

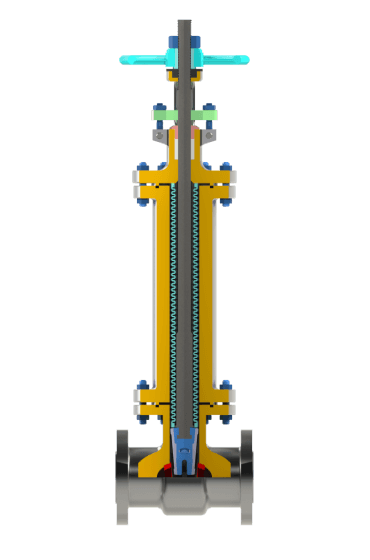

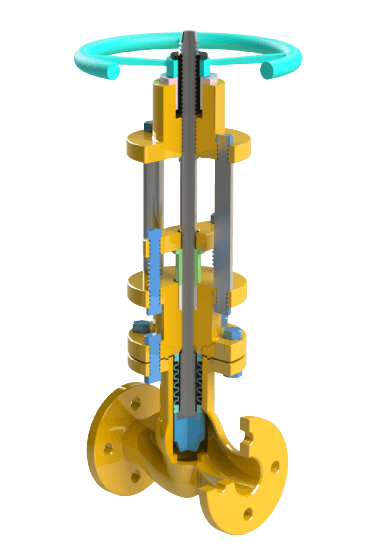

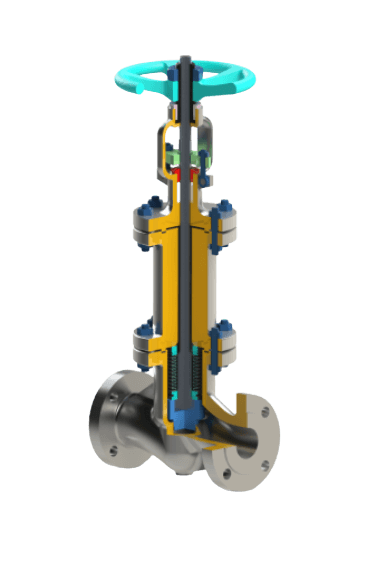

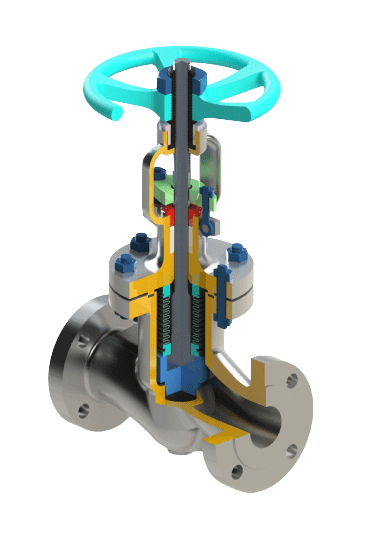

We are leading Bellow Sealed Globe Valve manufacturer in Mumbai, India. A Bellow is contained within the valve, and the lower end of the stainless-steel / nickel alloy Bellow is welded to the stem to prevent the stem from being eroded by system fluid. The other end is inserted between the valve's body and cover to form a permanent seal.

This double seal structure prevents leakage; in the event that the bellow collapse, the stem packaging will prevent further leakage. The bellow are welded to the valve stem to provide steady operation and to eliminate valve stem vibration caused by the valve insert movement.

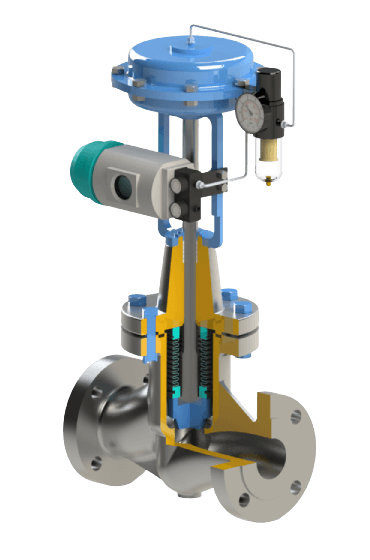

Bellow Sealed Globe Valve features a unique design that incorporates a non-rotating stem, which not only reduces the risk of bellow torsion but also significantly enhances the valve's cycle life. It is engineered to withstand extreme temperature ranges, from -190 °C to 350 °C, and is available in various sizes and pressure classes, accommodating diverse operational needs.

One of the standout features of this valve is its hermetic sealing technology, delivering zero emissions and ensuring environmental compliance. The robust construction provides maximum reliability, while the advanced stem and gland seal designs prevent leakage and ensure safe operation under line pressure.

With options for manual and actuated operation, including diaphragm, electric, gear, and cylindrical mechanisms, our Bellow Globe Valve is versatile and adaptable to any system requirements. Additionally, its minimal torque operation allows for efficient handling and reduces wear, resulting in lower maintenance costs over its lifecycle.

Choose our Bellow Sealed Globe Valve for its exceptional reliability, superior performance, and commitment to safety and sustainability. This valve not only meets but exceeds international standards, making it a smart choice for your critical applications.

Specifications | Features |

|---|---|

Type : Bellow Sealed Globe Valve End Connection: Flange (B16.5) / Butt Weld (B16.25) / Socket Weld (B-16.11) Size: 15 NB - 600 NB Class: #150 - #1500 Temperature Range: -190° C to 350 ° C MOC: Carbon Steel / Stainless Steel / Alloy Design Standard: MSS SP-117 / API 623 Cycle Life: 3000 - 5000 - 10000 Cycle Face to Face: ASME B16.10 Rev 2009 Operation: Manual & Actuated (Diaphragm / Electric / Gear / Cylindrical) Fire safe design: API 6FA Testing: API 598 Rev 2009 / ISO 15848 Documents: BS/EN 10204-3.1 REV 2019 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Bellow Seal Globe Valve?

- How does it work?

It uses a flexible metallic bellows to seal the valve stem, expanding or contracting to open or close the valve while maintaining a hermetic seal.

- What are the main applications ?

Used in chemical processing, oil and gas, pharmaceuticals, power generation, nuclear, and cryogenics for handling hazardous, high-temperature, or cryogenic media.

- What are the benefits of using one?

Benefits include superior leak prevention, enhanced safety, durability in extreme conditions, reduced maintenance, and increased service life.

- What materials are used in their construction?

Typically made from stainless steel, carbon steel, alloy steel, and special materials like Hastelloy or Inconel, with bellows made from high-grade stainless steel or corrosion-resistant alloys.

- How do I choose the right one for my application?

Consider the type of media, operating conditions, flow rate, industry standards, and appropriate materials and design features.

- Can they be repaired?

Yes, but repairs should be done by qualified professionals or the manufacturer to ensure integrity and performance.

- What maintenance is required?

Minimal maintenance is needed, with regular inspections and adherence to the manufacturer’s guidelines for optimal performance.

- Are they available in different designs?

Yes, available in straight, angle, and Y-pattern designs, with options for manual, pneumatic, or electric actuation.

- Why is Freture the best place to buy from?

Governed by standards like API, ASME, ANSI, DIN, and ISO for safety, quality, and performance.

Industries where Bellow Sealed Globe Valve is Used

Chemical Processing

Pharmaceutical Industry

Petrochemical Plants

Oil & Gas Refineries

Power Generation

Applications of Bellow Sealed Globe Valve:

- Chemical Processing: Handles corrosive and toxic chemicals.

- Oil and Gas: Prevents leaks in pipelines and refineries.

- Pharmaceuticals: Ensures contamination-free processes.

- Power Generation: Manages steam and high-temperature fluids.

- Nuclear Industry: Controls radioactive fluids and gases.

- Cryogenics: Maintains integrity in low-temperature applications.