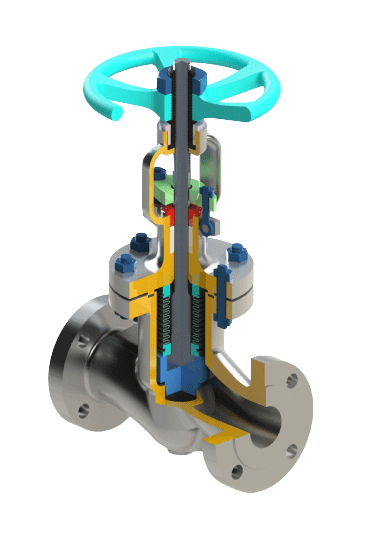

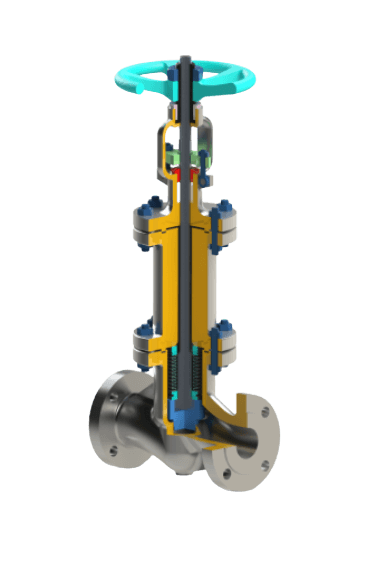

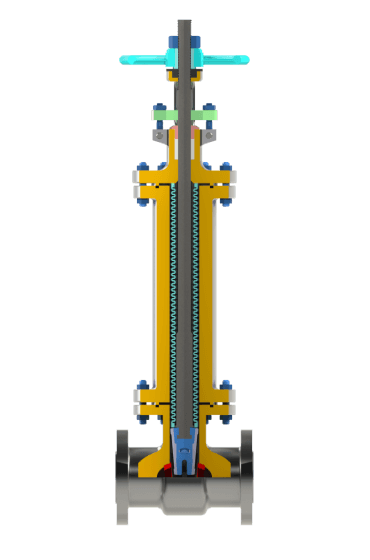

It is a type of Gate Valve designed with a metallic bellows to provide a hermetic seal, preventing any leakage from the valve stem. This design is particularly useful in applications where preventing leakage of hazardous or toxic substances is critical.

Bellow Seal Gate Valve

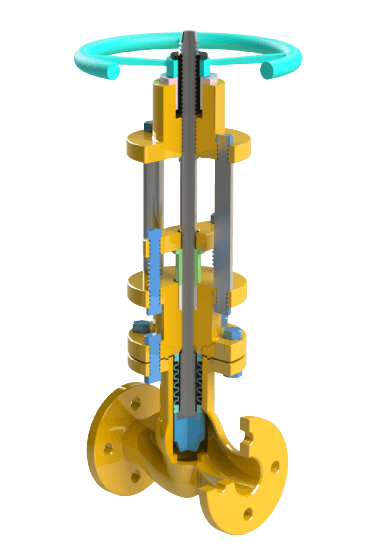

It is a construction that is a kind of Std. API 6D Extended Stem Gate Valve that seals the valve stem components using bellow.

We are a leading Bellow Sealed Gate Valve manufacturer in Mumbai, India. In the world of fluid control, precision engineering and reliable performance are paramount. Freture Techno, a distinguished name in valve manufacturing, proudly presents its Bellow Seal Gate Valves, setting new standards in fluid control excellence. They are meticulously crafted to offer impeccable sealing, superior performance, and unmatched durability, making them the preferred choice for a wide range of industries. With innovative bellow seal technology at their core, Ensure leak-free operations, safeguarding against fluid leakage and environmental contamination. Whether you seek precision, reliability, or versatility, Exemplify the perfect blend of engineering innovation and unwavering commitment to customer satisfaction. Explore a world of fluid control possibilities with Freture Techno, where precision truly meets performance.

Bellow Sealed Gate Valve API 600: Ensuring Leak-Free Performance

They are meticulously engineered to provide impeccable sealing and superior performance. Here's why they are the preferred choice:

- Robust Construction: Crafted from high-quality materials, it is built to withstand challenging industrial environments, ensuring long-term durability.

- Leak-Free Design: The innovative bellow seal technology guarantees a leak-free operation, preventing any fluid leakage or environmental contamination.

- Unidirectional Flow: Engineered for unidirectional flow, ensure precise fluid control while minimizing the risk of backflow.

- Low Maintenance: With minimal moving parts and a design that prioritizes ease of maintenance, It reduces downtime and operating costs.

- Wide Range of Applications: Ideal for various industries, including chemical, petrochemical, pharmaceuticals, and more, Adapt to diverse fluid control needs.

Why Choose Freture Techno?

At Freture Techno, we offer more than just exceptional valves:

- Quality Assurance: Adhere to stringent quality standards, guaranteeing reliability and consistency.

- Expertise: With years of experience in valve manufacturing, we possess the expertise to meet the most demanding requirements.

- Global Presence: Serving clients worldwide, we ensure access to top-quality, no matter where your operations are located.

- Dedicated Support: Our customer support team is committed to assisting you at every stage, from valve selection to post-installation service.

- Competitive Pricing: We offer competitive pricing without compromising on product quality, making cost-effective choice for your fluid control needs.

Choose Freture Techno for your Bellow Sealed Gate Valve requirements, and experience a blend of cutting-edge technology and unwavering commitment to customer satisfaction. Contact us today to discover how our valves can elevate your fluid control systems.

Specifications | Features |

|---|---|

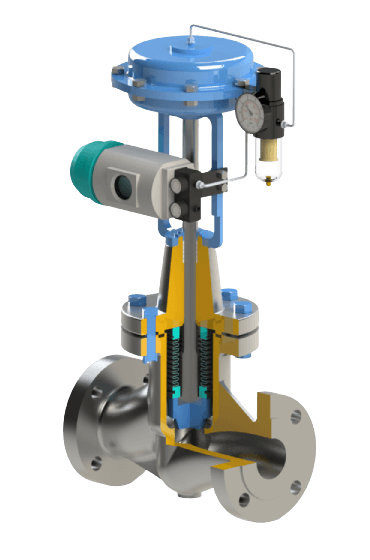

Type : Bellow Seal Gate Valve End Connection: Flange (B16.5) / Butt Weld (B16.25) / Socket Weld (B-16.11) Size: 15 NB - 600 NB Class: #150 - #900 Temperature Range: -190° C to 350 ° C MOC: Carbon Steel / Stainless Steel / Alloy Design Standard: API 6D / API 600 / API 594 Cycle Life: 3000 - 5000 - 10000 cycles Face to Face: ASME B16.10 Rev 2009 Operation: Manual & Actuated (Diaphragm / Electric / Gear / Cylindrical) Fire Safe Design: API 6FA Testing: API 598 Rev 2009 / ISO 15848 Documents: BS/EN 10204-3.1 REV 2019 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Bellow Seal Gate Valve?

- How does it work?

The bellow in the seal gate valve expands and contracts with the movement of the valve stem, creating a tight seal that prevents fluid from leaking. This expansion and contraction allow the valve to open and close while maintaining a hermetic seal.

- What are the main applications?

They are commonly used in industries where leakage of fluids, especially hazardous or toxic ones, cannot be tolerated. This includes chemical processing, nuclear power plants, pharmaceuticals, and petrochemical industries.

- What are the benefits of using one?

Leak-free performance: The bellows design ensures a hermetic seal, preventing leaks. Long service life: Reduced stem wear and corrosion lead to a longer operational life. Maintenance reduction: With minimal leakage and wear, the need for frequent maintenance is decreased. Safety: Ideal for handling toxic, hazardous, or high-purity fluids, ensuring safety and environmental compliance.

- What materials are used in their construction?

They are typically made from materials compatible with the fluids they will handle. Common materials include stainless steel, alloy steels, and high-grade carbon steel. The bellows themselves are often made from stainless steel or other corrosion-resistant alloys.

- How do I choose the right one for my application?

When selecting this Valve, consider factors such as: Fluid type and properties: Ensure material compatibility. Pressure and temperature ratings: Choose a valve that can withstand the operational conditions. Size and flow requirements: Select a valve that matches your system’s size and flow needs. End connections: Ensure the valve connections are compatible with your piping system.

- Can they be repaired?

Yes, these valves can often be repaired. However, due to their specialized design, it is usually recommended to have them serviced by professionals with experience in handling and repairing such valves to ensure integrity and performance are maintained.

- What maintenance is required?

It require minimal maintenance compared to conventional gate valves. Regular inspection for signs of wear or damage, especially to the bellows, is essential. Lubrication of the stem and checking the operation for smooth performance are also recommended.

- Are they available in different designs?

Yes, they come in various designs to suit different applications. This includes different types of bellows (such as multi-ply or single-ply), various end connections (flanged, welded, threaded), and different actuation methods (manual, pneumatic, electric).

- Why is Freture the best place to buy from?

Bellows Seal Gate valves are manufactured according to various international standards to ensure quality and safety. Common standards include ASME B16.34, API 600, DIN, and BS standards, which specify requirements for design, materials, testing, and performance.

If you have any other questions or need further details, feel free to ask!

Industries where Bellow Seal Gate Valve is Used

Oil and Gas Rifineries Industry

Natural Gas Industry

Synthetic & Textile

Paper and Pulp

Chemical & Petro-Chemical

Applications of Bellow Seal Gate Valve

- Chemical and Petrochemical: Prevent leakage of hazardous chemicals.

- Pharmaceutical: Ensure sterile, contaminant-free environments.

- Oil and Gas: Handle high-pressure, high-temperature fluids safely.

- Power Generation: Maintain efficiency and safety in power plants.

- Cryogenics: Ensure tight seals at extremely low temperatures.