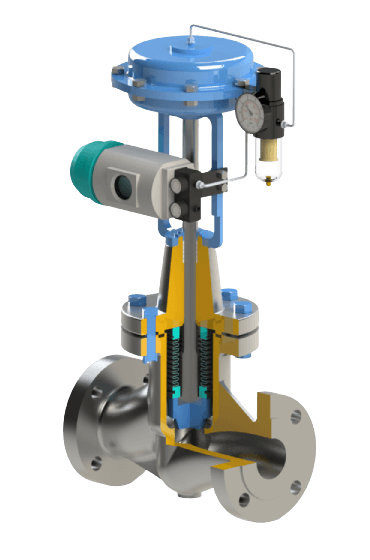

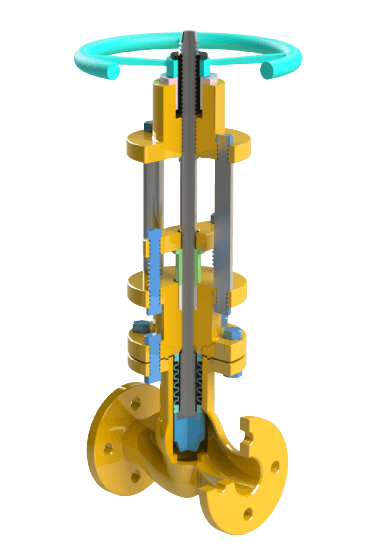

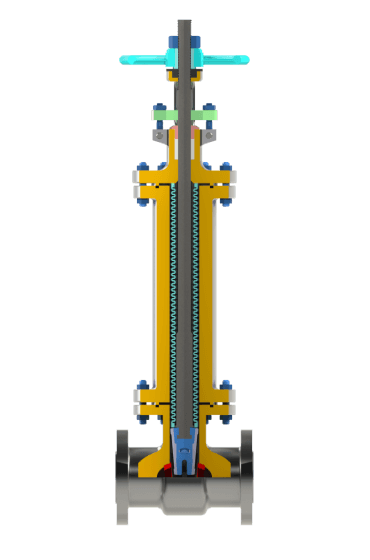

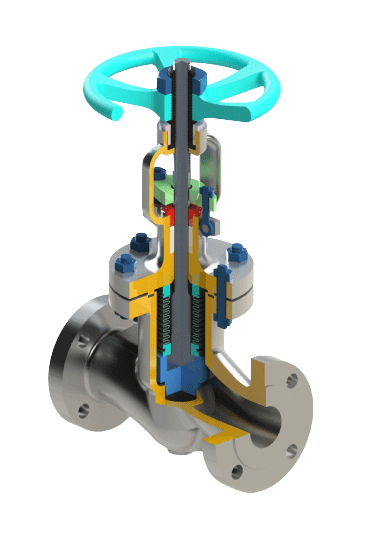

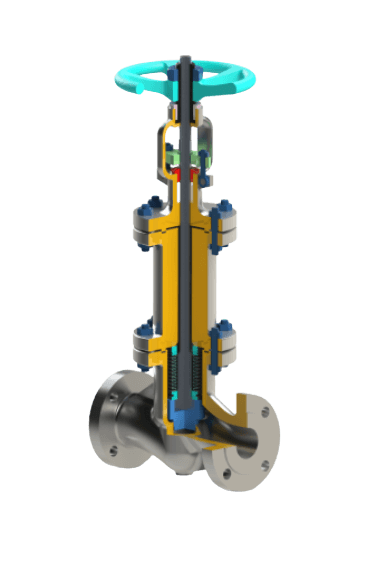

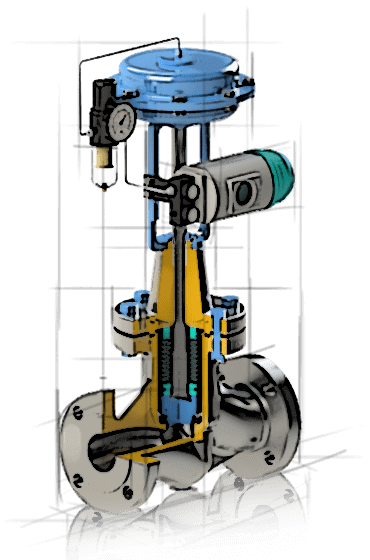

A Bellow Seal Valve is a type of valve designed with a metal bellows to provide a leak-proof seal around the valve stem, preventing fluid leakage and ensuring safe handling of hazardous substances. This type includes gate, globe, and control valves.

Bellow Sealed Valves

It ensure reliable, leak-free performance in demanding industrial environments.

At Freture Techno Pvt. Ltd., we take pride in being a leading manufacturer and supplier of Bellow Sealed Valves in Mumbai, India.

Freture Bellow Sealed Valves incorporate a formed multi-ply bellow that is welded to the stem and bottom of the bonnet, forming a hermetic seal or impermeable barrier.

Bellow are available in a wide variety of materials and can be used in practically any corrosive chemical application, reliable and high-quality Bellow Sealed Valves. With a strong commitment to customer satisfaction and product excellence, Freture Techno has established itself as a trusted provider in the industry. We will explore the key features and benefits of Freture Techno's Bellow Sealed Valves, highlighting why they are the ideal choice for your fluid control needs.

Innovative Designs For Improved Performance

Superior Quality and Durability: At Freture Techno, quality is of the utmost importance. We manufactured Bellow Valves using premium materials that ensure durability and long-lasting performance. These valves undergo rigorous testing and quality checks to meet international standards and provide reliable operation even in demanding environments.

Zero-Leakage Design: They are designed to provide a zero-leakage solution, ensuring the safety of personnel and the integrity of the system. The incorporation of a flexible metal Bellow eliminates the possibility of fluid or gas leakage through the Valve stem, making it an ideal choice for applications involving hazardous or corrosive substances.

Custom Manufacturing For Industrial Needs

Understanding that different industries have unique requirements, Freture Techno offers customizable solutions to meet specific needs. We work closely with customers to understand their application demands and provide tailored Bellow Sealed Valves that deliver optimal performance and efficiency.

Reliable Solutions For Critical Applications

Wide Range of Applications: including chemical processing, oil and gas, pharmaceuticals, and more. These Valves excel in critical processes where leak-free operation is essential. Whether it's controlling the flow of aggressive chemicals or maintaining sterile conditions in pharmaceutical manufacturing, Freture Techno's Bellow Seal Valves offer the reliability and performance required.

Expert Technical Support: Freture Techno goes beyond just supplying Bellow Sealed Valves. We have a team of experienced professionals who provide expert technical support and guidance throughout the selection and installation processes. Whether you have questions about Valve specifications, installation procedures, or maintenance requirements, the knowledgeable staff at Freture Techno is always ready to assist you.

Competitive Pricing and Timely Delivery: We understand the importance of cost-effectiveness and timely delivery. We offer competitive pricing without compromising on quality, ensuring that customers receive the best value for their investment. With a streamlined production process and efficient logistics, Freture Techno ensures on-time delivery, minimizing downtime, and maximizing operational efficiency.

Bellow Valves For Process Control in Manufacturing

When it comes to Bellow Seal Valve manufacturers and suppliers in India, Freture Techno stands out as a trusted partner. With superior quality, zero-leakage design, customizable solutions, a wide range of applications, expert technical support, and competitive pricing, Freture Techno is the go-to choice for all your Bellow Valve needs. We have a range of bellow valves, such as Bellow Seal Gate Valve, Bellow Seal Globe Valve, Bellow Seal Euro-Chlor Valve, and Ext. Steam Bellow Seal Valve. Experience peace of mind and reliable performance by choosing Freture Techno as your trusted Bellow Sealed Valves manufacturer in Mumbai, India.

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Bellow Seal Valve?

- How does it work?

A Bellow Seal Valve operates by using a metallic bellows to isolate the process fluid from the external environment. When the valve is actuated, the bellows expand or contract, allowing the valve to open or close while maintaining a tight seal, preventing any leakage.

- What are the main applications?

Bellow Seal Valves are used in industries where leakage prevention is crucial, such as chemical processing, petrochemicals, pharmaceuticals, and power generation. They are ideal for handling toxic, corrosive, or high-purity fluids.

- What are the benefits of using one?

- Zero leakage: The bellow design ensures there is no leakage along the valve stem.

- Longer lifespan: The bellows prevent corrosive or harmful fluids from coming into contact with the stem, extending the valve's operational life.

- High reliability: Ideal for critical applications where valve failure or leakage cannot be tolerated.

- What materials are used in their construction?

Bellow Seal Valves are typically made from materials such as Carbon Steel, Stainless Steel, and various Alloys. The choice of material depends on the application, including fluid type, operating pressure, and temperature./p>

- How do I choose the right one for my application?

Choosing the right Bellow Seal Valve involves considering factors like: Type of fluid Operating pressure and temperature Required flow capacity Compatibility with existing piping systems Compliance with industry standards and regulations Consulting with a valve specialist can help in selecting the appropriate valve for your needs.

- Can they be repaired?

Yes, Bellow Seal Valves can be repaired. The feasibility and cost-effectiveness of repairs depend on the extent of wear and damage. Regular maintenance and inspections can help identify issues early and extend the valve's service life.

- What maintenance is required?

Maintenance for Bellow Seal Valves includes regular inspections for wear or damage, lubrication of moving parts, and periodic testing to ensure proper operation. Adhering to the manufacturer's maintenance guidelines is essential for optimal performance and longevity.

- Are they available in different designs?

Yes, Bellow Seal Valves are available in various designs to meet specific application requirements. This includes different types such as gate, globe, and control valves, with various end connections, pressure ratings, and materials of construction. Custom designs may also be available.

Industries where Bellow Sealed Valve is used

Chemical Maufacturing

Oil and Gas Industry

Power Generation

Petrochemicals Industry

Refineries

Applications

- Leak Prevention: Ensures a hermetic seal to prevent fluid leaks.

- Hazardous Media : Safely handle toxic or reactive substances.

- High-Temperature Use : Withstands thermal expansion in high heat.

- Cryogenic Services : Maintains tight seals at very low temperatures.

- Low Maintenance : Reduces maintenance by eliminating packing leaks.