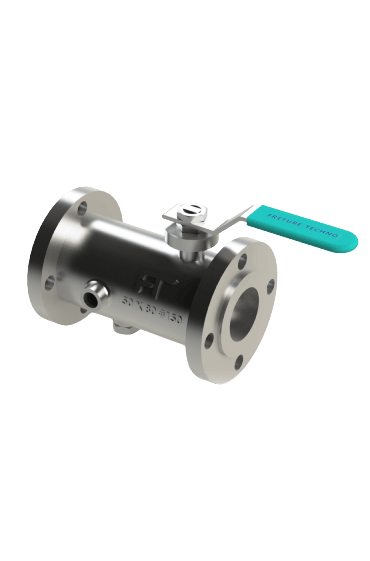

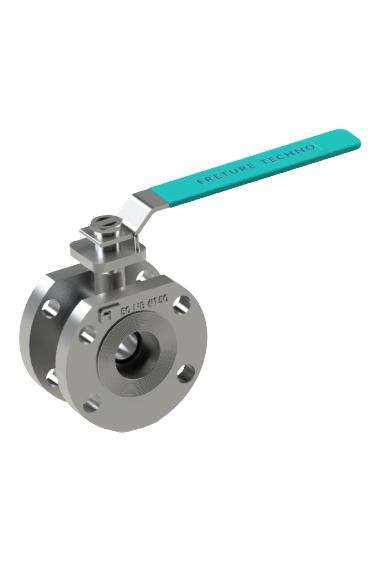

A trunnion mounted ball valve is a type of industrial valve that utilizes a fixed pivot point, known as a trunnion, to support the ball. This design enhances the valve's stability and allows it to handle higher pressures and larger sizes compared to floating ball valves.

Trunnion Mounted Ball Valves

API 6D Trunnion Mounted Ball Valve is a quarter-turn valve.

Freture Techno is a leading Trunnion Mounted Ball Valve manufacturer in Mumbai, India. When it comes to fluid control solutions, the Trunnion Ball Valve stands as a hallmark of precision engineering and efficient performance. At Freture Techno, we take pride in offering top-of-the-line Ball Valves, meticulously designed to meet the most demanding industrial requirements.

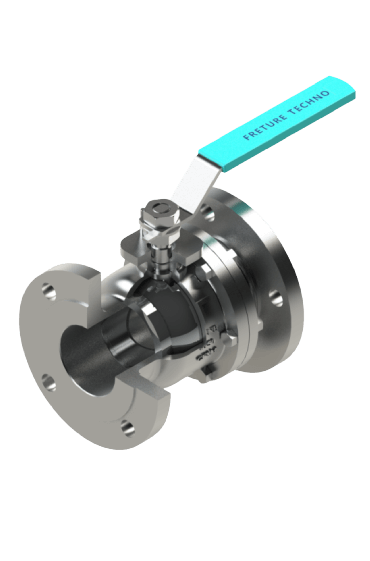

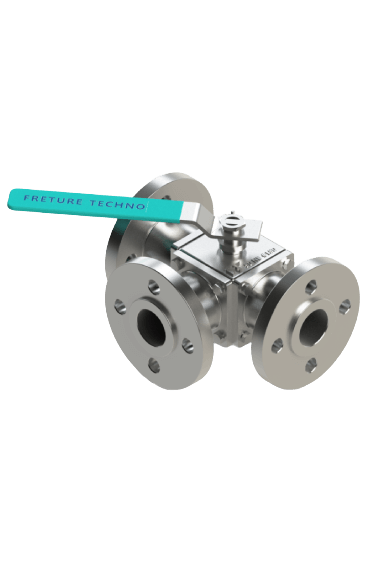

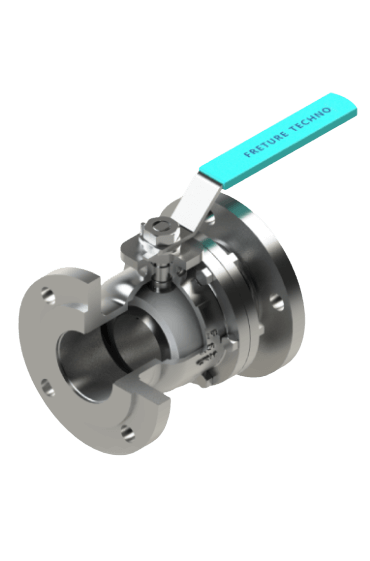

In a floating ball valve, the ball floats depending on the pressure. Whereas in a Two piece / Three Piece Trunnion Mounted Ball Valve, the ball is held in place by the stem of one pipe and the shaft of the other. The ball doesn’t float.

Flaoting Trunnion Mounted Ball Valve Features:

- Robust Construction: These are built to last, crafted from high-quality materials to withstand the harshest operating conditions.

- Efficient Flow Control: These valves provide precise control over fluid flow, minimizing pressure drop and ensuring leak-free operation.

- Unidirectional Sealing: Engineered for unidirectional flow, they prevent backflow, enhancing safety and system integrity.

- Versatility: Suitable for a wide range of applications across industries, including oil and gas, petrochemicals, power generation, and more.

- Low Maintenance: With a design that minimizes wear and tear, our valves are low-maintenance, reducing downtime and operational costs.

Why Choose Freture Techno?

At Freture Techno, we go beyond delivering products; we provide solutions. Here's why we are your ideal partner for Trunnion Mounted Ball Valves:

- Quality Assurance: Our valves adhere to international standards and undergo rigorous testing to ensure reliability and performance.

- Expertise: With years of experience in fluid control solutions, we have the knowledge and skill to meet your specific needs.

- Global Reach: We serve clients not only locally but also globally, offering access to premium Ball Valves wherever your operations are located.

- Exceptional Support: Count on our dedicated customer support team for assistance, from product selection to post-installation service.

- Competitive Pricing: We offer competitive pricing without compromising on product quality, making our Ball Valves a cost-effective choice.

Choose Freture Techno for your Ball Valve requirements and experience excellence in fluid control. Contact us today to discover how Ball valves can elevate your industrial operations.

Description | Features |

|---|---|

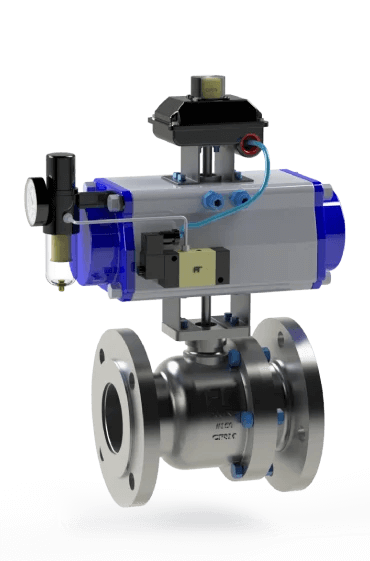

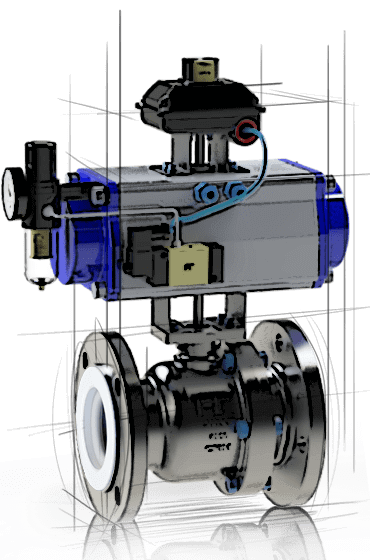

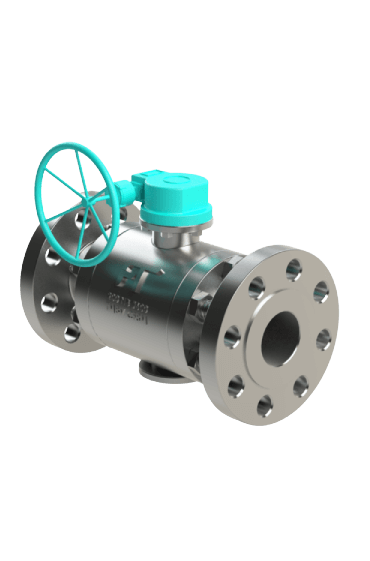

TYPE: Two Piece / Three Piece Trunnion Mounted Size: 15NB - 300NB End Connection: Flange / Buttweld/ Socket Weld / screwed Pressure Rating: 150# - 2500# Temperature Range: -7Deg C to 280 Deg C Body Materials: Stainless Steel / Carbon Steel / Alloys Design Standard: API 6D / ISO 17292 / ASME B16.34 / API 607 End Connection Std.: ASME B16.5 / ASME B16.25 Operation: Manual & Actuated (Rack & Pinion / Scotch Yoke / Electric) Gear Operated Face to Face: ASME B16.10 Rev 2009 Operation: Manual & Actuated (Rack & Pinion / Scotch Yoke / Electric) Gear Operated Fire safe design: API-607 Rev 2010 Testing: API 598 Rev 2009 Sour Service: NACE MOR 0175 Rev 2009 Documents: BS/EN 10204-3.1 REV 2004 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a trunnion mounted ball valve?

- How does it work?

Trunnion Mounted Ball Valves operate by using a fixed ball to control the flow of fluid through the valve. The ball is held in place by trunnion bearings, allowing it to rotate and open or close the valve.

- What are the main applications?

Trunnion Mounted Ball Valves are commonly used in high-pressure and high-temperature applications, such as oil and gas pipelines, petrochemical plants, power plants, and refining processes.

- What are the benefits of using one?

The benefits of using Trunnion Mounted Ball Valves include superior sealing performance, high-pressure and high-temperature capabilities, reduced operating torque, and increased durability and reliability.

- What materials are used in their construction?

Trunnion Mounted Ball Valves are typically constructed from materials such as carbon steel, stainless steel, duplex steel, and various alloys, depending on the specific application requirements.

- How do I choose the right one for my application?

When selecting a Trunnion Mounted Ball Valve, consider factors such as pressure rating, temperature range, fluid type, valve size, end connections, and environmental conditions to ensure compatibility with your application.

- Can they be repaired?

Yes, Trunnion Mounted Ball Valves can be repaired. Common repairs may include replacing worn seals, bearings, or other components to restore the valve's functionality.

- What maintenance is required?

Regular maintenance of Trunnion Mounted Ball Valves typically includes inspection, lubrication of moving parts, and replacement of worn or damaged components as needed to ensure optimal performance and reliability.

- Are they available in different designs?

Yes, Trunnion Mounted Ball Valves are available in various designs to suit different applications, including full bore and reduced bore configurations, as well as different seat and seal materials to accommodate specific operating conditions.

- Why is Freture the best place to buy from?

Freture is the preferred choice for purchasing Trunnion Mounted Ball Valves due to our commitment to quality, precision engineering, extensive industry experience, and dedication to customer satisfaction. We offer a wide range of high-quality valves, expert technical support, and competitive pricing, ensuring that our customers receive reliable solutions tailored to their needs.

Industries where Trunnion Ball Valve is Used

Oil and Gas Industry

Petrochemicals

Power Generations

Chemical Processing

Pulp and Paper Industry

Applications of Trunnion Ball Valve

- Pipeline Flow Control: Efficiently regulates fluid flow in pipelines.

- High-Pressure Applications: Ideal for reliable performance under high-pressure conditions.

- Critical Process Control: Essential for precise fluid management in critical processes.

- Tank and Vessel Isolation: Ensures secure shut-off and prevents backflow in tanks and vessels.

- Emergency Shutdown Systems: Enable quick and secure valve closure during critical situations.