It is a type of valve equipped with metal-to-metal seating surfaces, providing excellent sealing performance and durability in high-temperature and abrasive applications.

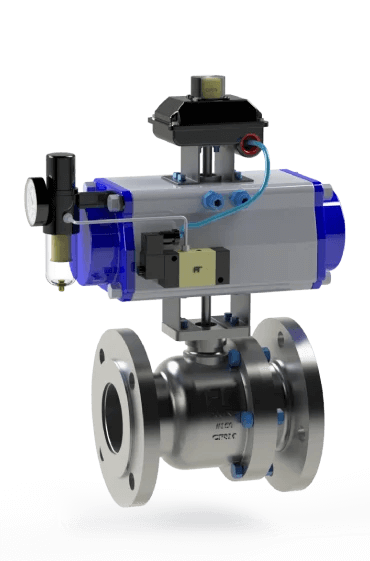

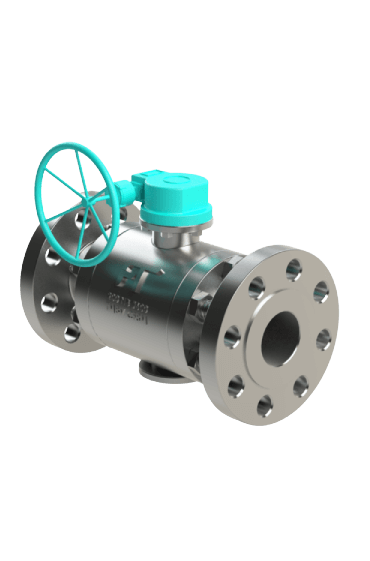

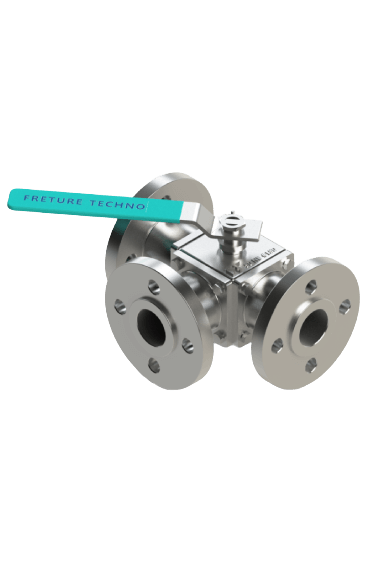

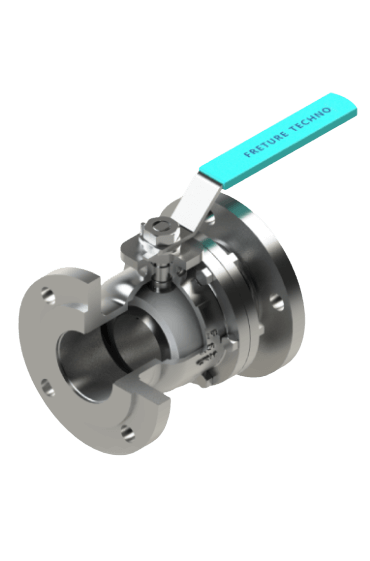

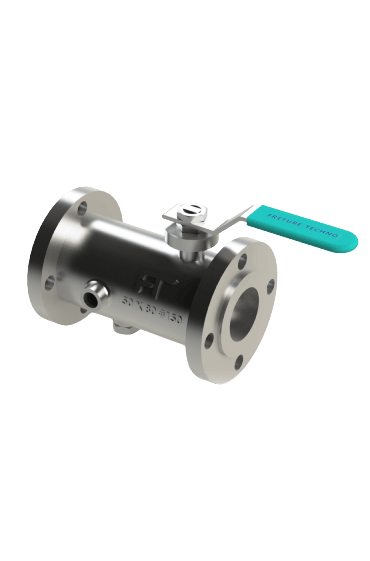

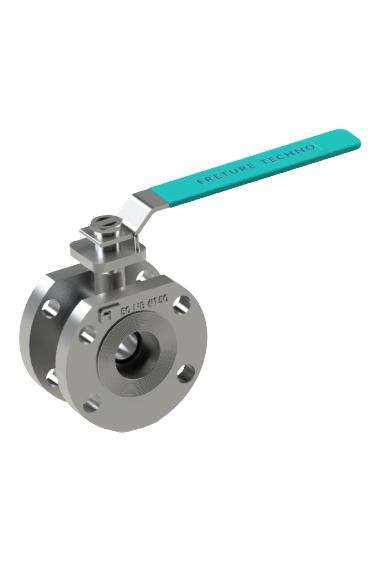

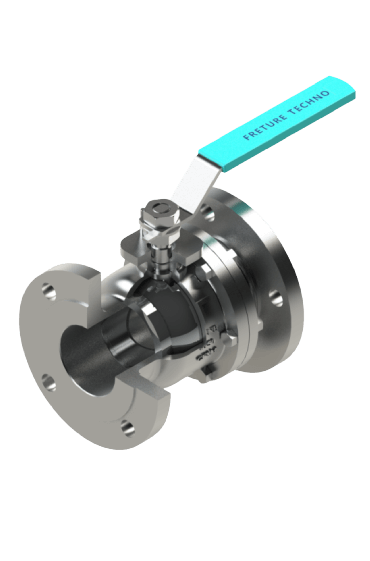

Metal Seated Ball Valve

If durability and efficiency is what you’re looking for, Metal Seated Ball Valves will be ideal for you.

Freture Techno is a leading Metal Seated Ball Valve manufacturer in Mumbai, India. This Ball Valve is made up of sturdy stainless steel metal seats with high tensile strength and balls coated with carbide. It works well in extremely harsh temperatures and pressure. It also functions flawlessly in systems where abrasives and corrosives are involved.

The design of this Ball Valve is such that it provides maximum sealing capacity. Featuring a robust metal-to-metal seal, our metal-seated ball valves provide exceptional performance and longevity, reducing maintenance costs and downtime. With precision engineering and stringent quality control,

High-Quality Ball Valves for Leak-Proof Flow Control Solutions

These Ball valves guarantee leak-proof operation and excellent flow control. They are available in various sizes and pressure ratings to meet diverse application needs. Whether you require standard or customized solutions, we are committed to delivering high-quality, reliable metal seated ball valves that exceed your expectations. Trust us for your critical flow control needs.

Why Choose?

Ball valves are engineered for harsh environments involving abrasion, corrosion, high pressure, and extreme temperatures. Their robust design makes them ideal for handling slurry, steam, gas, and solid-laden media—where soft-seated valves often fail. Known for their durability and reliable sealing, these valves are essential in demanding applications across industries such as oil and gas, petrochemical, power generation, and others.

Whether you require standard specifications or customized configurations, we deliver long-term reliability, safety, and performance in the most challenging conditions. Backed by strict quality control and industry certifications, our valves are trusted by professionals worldwide for critical flow control applications. Contact us today to discuss your project requirements and discover the right valve solution for your industry.

With advanced engineering, high-grade materials, and precision manufacturing, These ball valves are built to exceed industry standards. From design to delivery, we ensure every valve performs flawlessly under extreme service conditions. Partner with us for dependable solutions that optimize process efficiency and reduce downtime across your operations.

Description | Features |

|---|---|

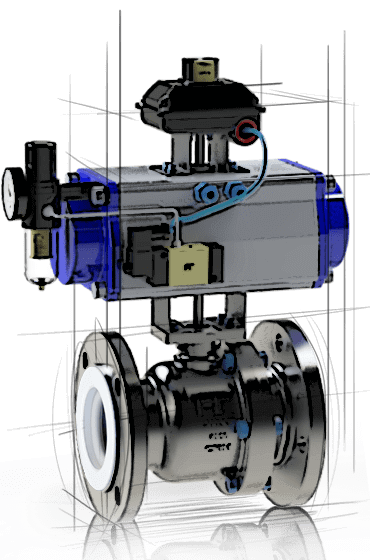

TYPE: Metal Seated Port: Full & Regular (Reduced) Bore Size: 15 NB to 300 NB Pressure Rating: 150# - 2500# Temperature Range: 35 Deg C to 538 Deg C (Soft Seated) Body Materials: Stainless Steel / Carbon Steel / Alloys Design Standard: API 6D rev 23; ISO 17292 rev 2004 End Flanges: ASME B16.5 2013 Face to Face Dimension: ASME B16.10 Rev 2009 Fire safe design: API-607 Rev 2010 Operation: Manual & Actuated (Rack & Pinion / Scotch Yoke / Electric) Gear Operated Testing: API 598 Rev 2009 Sour Service: NACE MOR 0175 Rev 2009 Documents: BS/EN 10204-3.1 REV 2004 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Metal Seated Ball Valve?

- How does it work?

It operates by using a metal ball with a matching metal seat. When the valve is closed, the ball rotates to create a tight seal against the seat, preventing fluid from flowing through the valve.

- What are the main applications?

Main applications include high-temperature processes in industries such as oil and gas, petrochemicals, power generation, refining, and mining.

- What are the benefits of using one?

Benefits include high-temperature resistance, excellent sealing performance, resistance to abrasion and wear, and longer service life compared to soft-seated valves.

- What materials are used in their construction?

These valves are typically constructed from materials such as stainless steel, carbon steel, alloy steel, and other high-strength metals to withstand extreme conditions.

- How do I choose the right one for my application?

Choose based on factors such as temperature, pressure, fluid type, and the severity of operating conditions to ensure compatibility with your specific application requirements.

- Can they be repaired?

Yes, these Ball Valves can be repaired by replacing the metal seating components and other worn or damaged parts as needed.

- What maintenance is required?

Regular maintenance includes inspection, cleaning, and lubrication of moving parts to ensure smooth operation and prevent corrosion or damage.

- Are they available in different designs?

Yes, these Ball Valves are available in various designs, including floating ball and trunnion mounted configurations, to suit different application needs.

- Why is Freture the best place to buy from?

Freture offers high-quality Metal Seated Ball Valves, backed by expert engineering, extensive industry experience, and a commitment to customer satisfaction. Our products are reliable, competitively priced, and tailored to meet the specific needs of your applications.

Industries where these Ball Valve is Used

Oil and Gas Industry

Petrochemical Industry

Power Generation Industry

Refining Industry

Pulp and Paper Industry

Application

High-Temperature Environments: Perfect for industries like oil and gas.

Abrasive Fluid Handling: Ideal for Mining Operations.

Severe Service Conditions: Reliable in Petrochemical Plants.

High-Pressure Applications: Suitable for Power Generation Plants.

Critical Fluid Control: Essential in the refining industry.