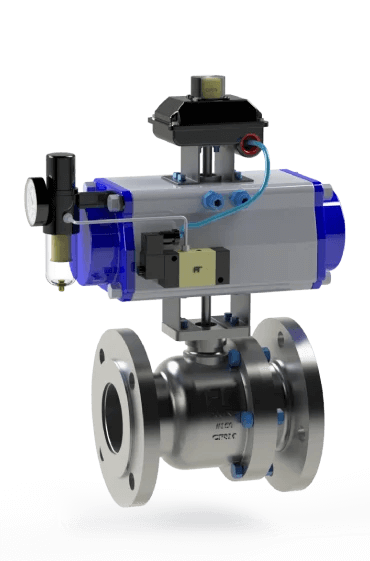

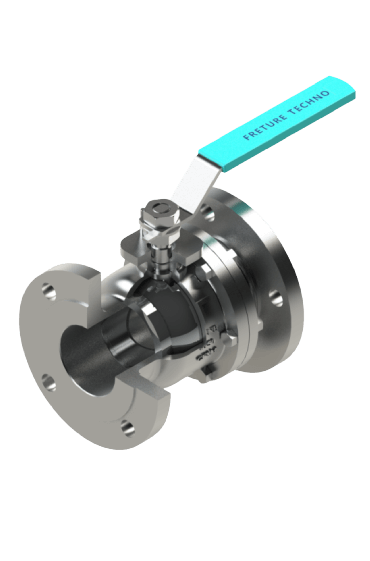

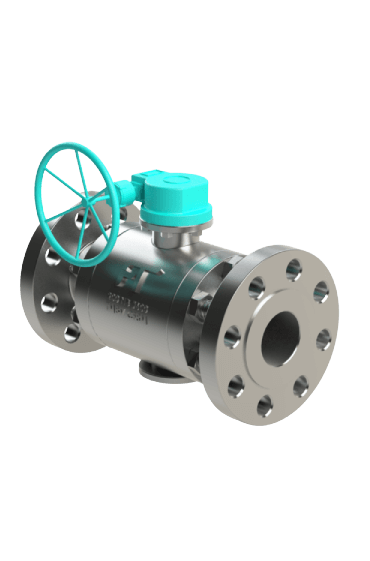

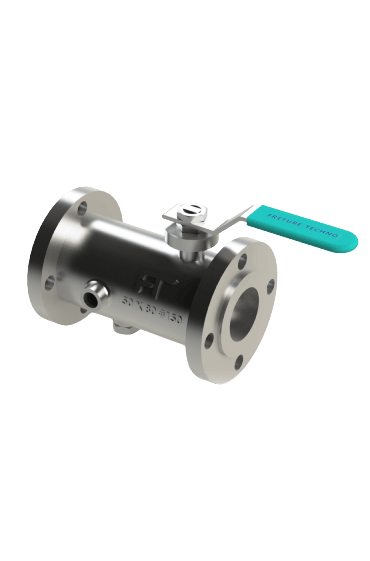

Jacketed Ball Valves are specialized flow control devices designed for applications where maintaining a consistent temperature of the process fluid is crucial. These valves feature an outer jacket that surrounds the valve body, allowing for the circulation of a heating or cooling medium to regulate the fluid's temperature.

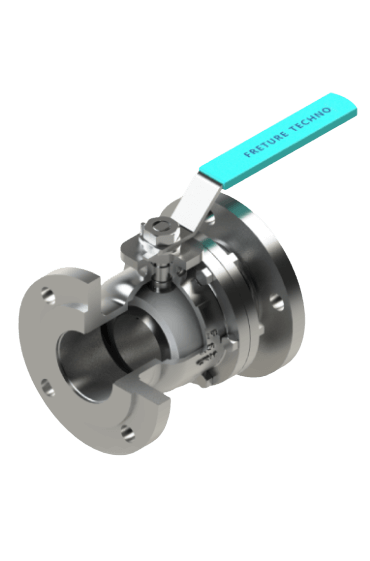

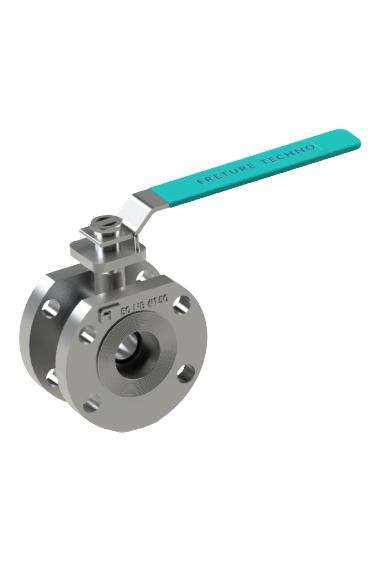

Jacketed Ball Valve

Jacketed Ball Valves are designed in Single-Piece Welded Jacket creation for Standard Bore valves.

Freture Techno is a leading jacketed ball valve manufacturer in Mumbai, India. The jacket extends from one flange to another and is typically oversize with head-to-head size of corresponding valve. The jacket is available in two-piece creation welded together. The jackets of the valves may be rated for warmth switch media stress of as much as 22 bars. In standard layout, the jacket is rated at 10.three bars.

The valve also can be utilized in FDA / sanitary applications. Jacketed Ball valves to address viscous substances or substances that solidify at ambient temperatures are to be used with steam or any other warmth switch media. Also to be had in #600 to #2500 pressure rating (Custom valve)

Description | Features |

|---|---|

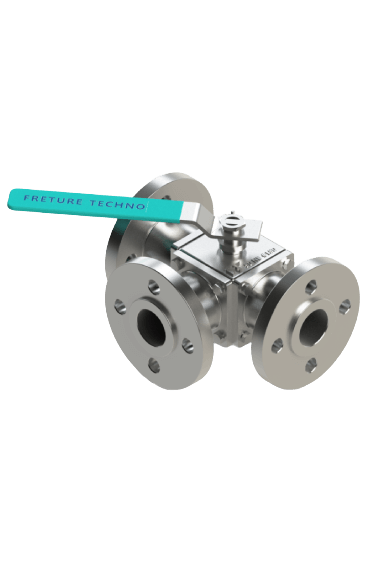

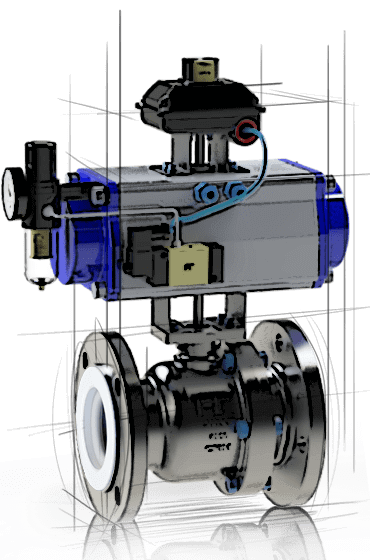

TYPE: Single Piece Flanged End Jacketed Ball Valve Port: Full Bore End Connection: Flange Size: 15 NB- 300 NB Class: 150# - 2500# Temperature Range: 35° C to 280°C Body Materials: Stainless Steel / Carbon Steel / Alloys Design Standard: API 6D / ISO 17292 / ASME B16.34 / API 607 Face to Face Dimension: ASME B16.10 Rev 2009 Operation: Manual & Actuated (Rack & Pinion / Scotch Yoke / Electric) Gear Operated Fire safe design: API-607 Rev 2010 Testing: API 598 Rev 2009 Sour Service: NACE MOR 0175 Rev 2009 Documents: BS/EN 10204-3.1 REV 2004 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What are Jacketed Ball Valves?

- How does it work?

Jacketed Ball Valves work by using a secondary outer casing (jacket) surrounding the valve body. This jacket allows for the circulation of a heating or cooling medium, maintaining the temperature of the fluid inside the valve.

- What are the main applications?

Jacketed Ball Valves are commonly used in industries such as chemical processing, pharmaceuticals, food and beverage, and oil and gas, where temperature-sensitive fluids need to be controlled and maintained at specific temperatures.

- What are the benefits of using one?

The benefits of using Jacketed Ball Valves include precise temperature control, prevention of fluid solidification or crystallization, protection against freezing, and the ability to handle viscous or sticky fluids.

- What materials are used in their construction?

Jacketed Ball Valves are typically constructed using materials such as stainless steel, carbon steel, or other alloys for the valve body, and the jacket is often made of the same or compatible material.

- How do I choose the right one for my application?

When selecting a Jacketed Ball Valve, consider factors such as the temperature range, pressure rating, fluid type, valve size, end connections, and compatibility with the specific application requirements to ensure optimal performance.

- Can they be repaired?

Yes, Jacketed Ball Valves can be repaired. Common repairs may include replacing worn seals, bearings, or other components to restore the valve's functionality.

- What maintenance is required?

Regular maintenance of Jacketed Ball Valves typically includes inspection, cleaning, and lubrication of moving parts to ensure smooth operation and prevent corrosion or damage.

- Are they available in different designs?

Yes, Jacketed Ball Valves are available in various designs, including two-way, three-way, and multi-port configurations, as well as different end connections and actuation options to suit different application requirements.

- Why is Freture the best place to buy from?

Freture is the preferred choice for purchasing Jacketed Ball Valves due to our commitment to quality, extensive industry experience, and dedication to customer satisfaction. We offer a wide range of high-quality valves, expert technical support, and competitive pricing, ensuring that our customers receive reliable solutions tailored to their needs.

Industries where a Ball Valve is Used

Chemical Processing

Pharmacuticals

Petrochemical Industry

Food and Beverage

Oil and Gas Industry

Applications of Jacketed Ball Valve

- Chemical Processing: Controls corrosive fluids in manufacturing.

- Pharmaceutical Industry: Regulates high-purity compounds precisely.

- Food and Beverage Production: Handles food-grade materials at optimal temperature.

- Oil and Gas Transmission: Manages high-pressure fluids in pipelines.

- Bitumen and Asphalt Handling: Controls flow in road construction materials.

- Polymer and Plastic Processing: Ensures temperature control during molding.