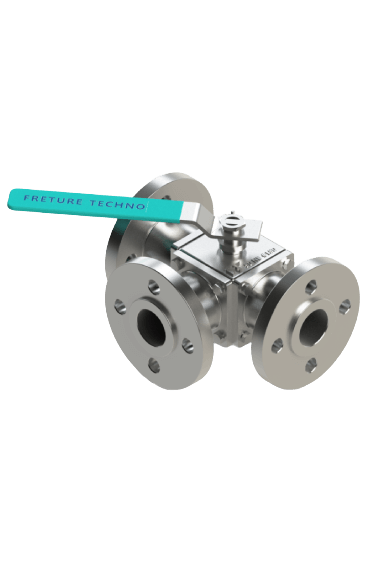

A 3 Way T Port Floating Ball Valve is a type of valve that allows fluid flow to be directed through three different ports arranged in a "T" configuration, enabling versatile flow paths.

3 Way Ball Valve

Improve efficiency. Save space and costs. A 3 Way T-port Ball Valve is often used as a replacement for two separate valves.

We are a leading manufacturer of 3 Way Ball Valves, specializing in high-quality solutions for complex flow control applications. Our 3 Way Ball Valves offer superior durability and efficiency, designed to handle a wide range of industrial fluids, including corrosive chemicals and high-temperature gases. Each 3 Way Ball Valve is meticulously engineered for seamless operation, ensuring minimal pressure drop and excellent sealing performance.

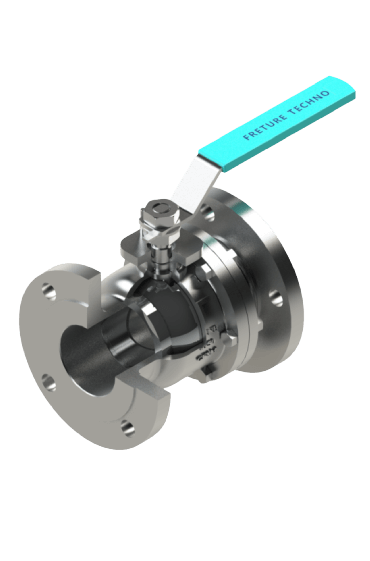

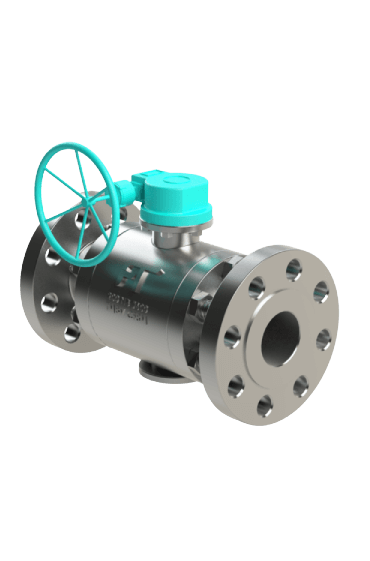

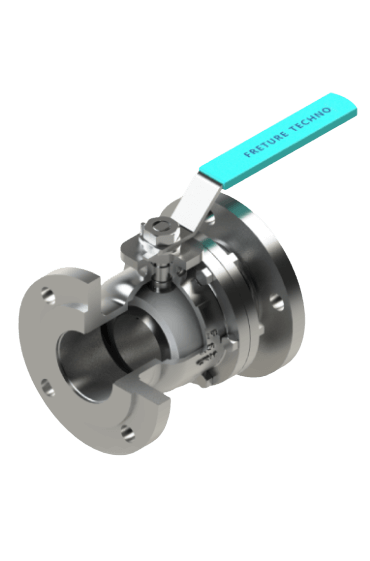

3 Way Ball Valves feature robust construction from premium materials such as stainless steel and carbon steel, providing exceptional resistance to wear and corrosion. The compact design of our 3 Way Ball Valve allows for easy installation and maintenance, making it an ideal choice for industries like chemical processing, petrochemical, pharmaceuticals, and food & beverage.

With our commitment to quality and innovation, our 3 Way Ball Valve are rigorously tested to meet stringent international standards. Trust us for reliable and efficient 3 Way Ball Valves tailored to your specific needs.

Description | Features |

|---|---|

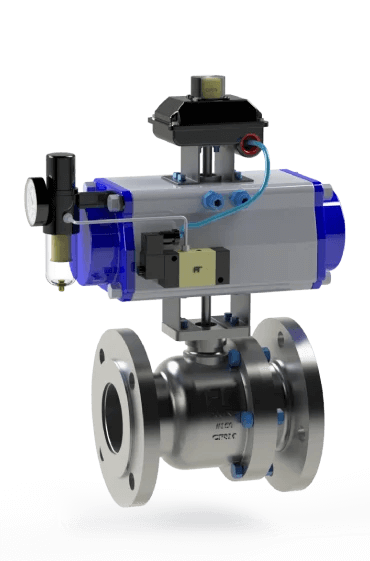

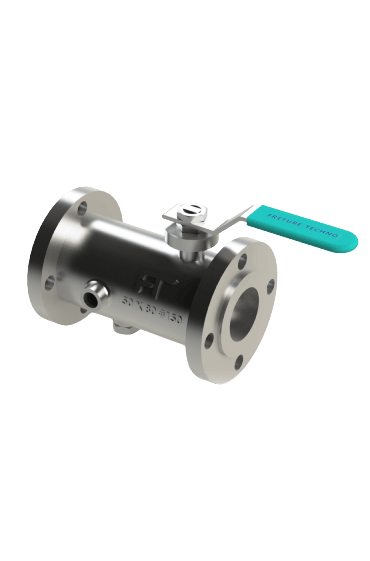

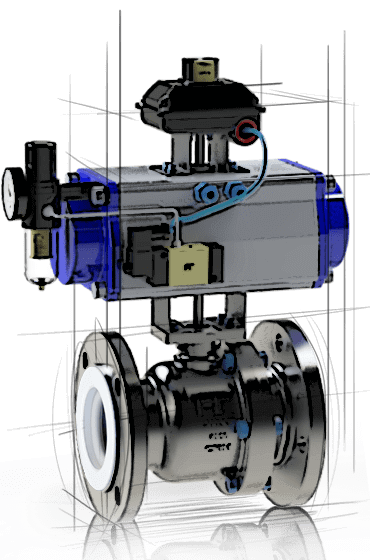

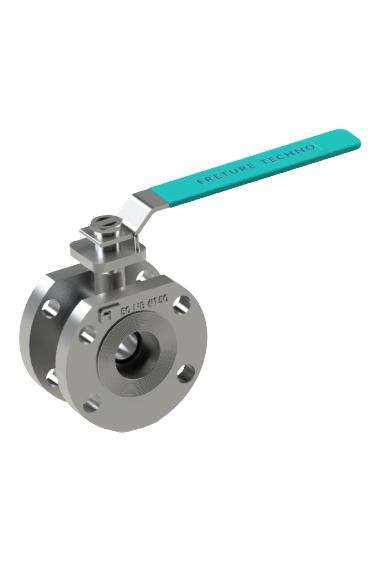

TYPE: 3 way T port Floating Ball Valve Port: Full Bore End Connection: Flange ( ASME B16.5 ) Size: 15 NB to 100 NB Class: 150# - 2500# Temperature Range: 35°C to 280°C (Soft Seated) Body Materials: Stainless Steel / Carbon Steel / Alloys Design Standard: API 6D rev 23; ISO 17292 rev 2004 Face to Face Dimension: ASME B16.10 Operation: Manual & Actuated (Rack & Pinion / Scotch Yoke / Electric) Gear Operated Fire safe design: API-607 Rev 2010 Testing: API 598 Rev 2009 Sour Service: NACE MOR 0175 Rev 2009 Documents: BS/EN 10204-3.1 REV 2004 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a 3 Way T Port Floating Ball Valve?

- How does it work?

It works by rotating the ball within the valve body, aligning the T-shaped port to direct flow between different paths, enabling mixing or diverting of the fluid.

- What are the main applications?

Main applications include fluid mixing, flow diversion, and distribution in industries such as chemical processing, HVAC systems, water treatment, and oil and gas.

- What are the benefits of using one?

Benefits include versatile flow control, reduced need for multiple valves, compact design, and efficient switching between flow paths.

- What materials are used in their construction?

These valves are typically made from materials such as stainless steel, carbon steel, and various alloys, with seals made from PTFE or other suitable polymers.

- How do I choose the right one for my application?

Choose based on factors like fluid type, pressure, temperature, valve size, and compatibility with your specific application needs.

- Can they be repaired?

Yes, 3 Way T Port Floating Ball Valves can be repaired by replacing worn or damaged seals and other components.

- What maintenance is required?

Regular maintenance includes inspection, lubrication of moving parts, and replacement of seals to ensure optimal performance.

- Are they available in different designs?

Yes, they are available in various designs, including different port configurations, end connections, and actuation options.

- Why is Freture the best place to buy from?

Freture offers high-quality 3 Way T Port Floating Ball Valves, backed by expert engineering, extensive industry experience, and a commitment to customer satisfaction, providing reliable and tailored solutions for your needs.

Industries where 3 Way T Port Floating Ball Valve is Used

Chemical Processing

HVAC Systems

Water Treatment Industry

Pharmaceutical Industry

Oil and Gas Industry

Application of 3 Way Ball Valve

- Flow Diversion: Directs fluid flow between different process lines.

- Fluid Mixing: Combines fluids from two different sources into one.

- Distribution Control: Manages fluid distribution to multiple outlets.

- Tank Switching: Alternates flow between multiple storage tanks.

- System Isolation: Isolates parts of a system for maintenance or repair.