It is a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of liquids or gases through it.

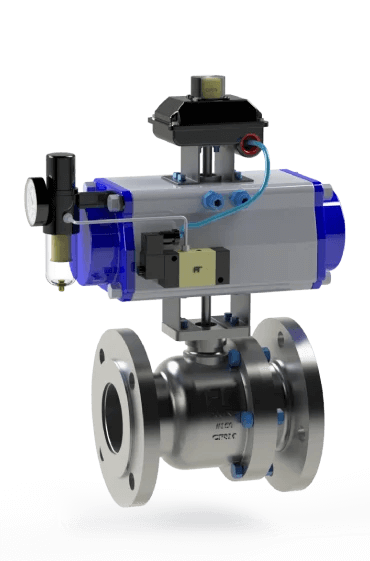

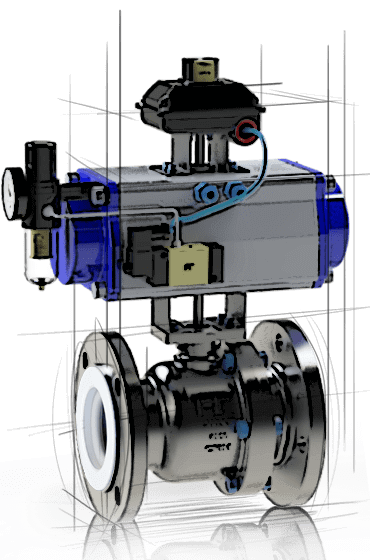

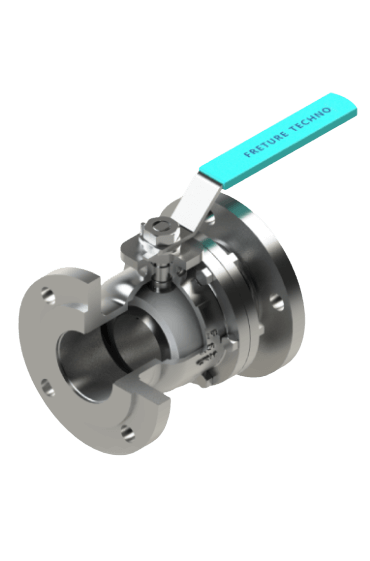

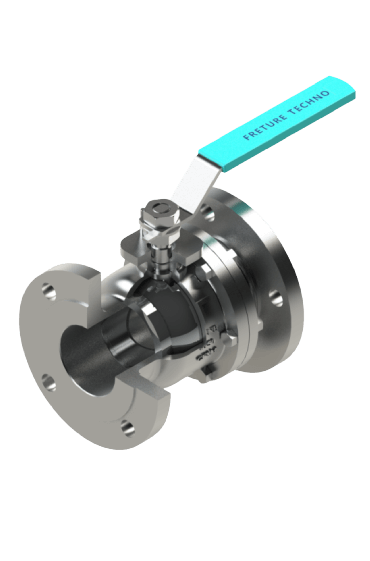

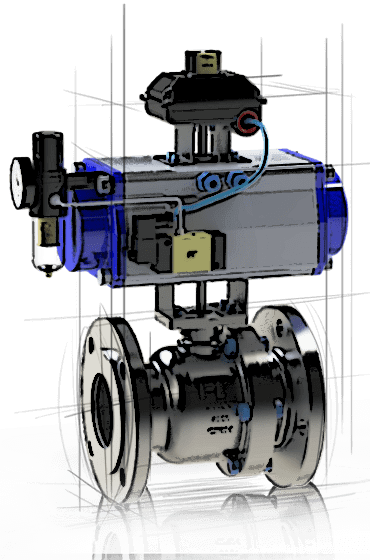

Ball Valves

It is extremely safe and reliable.

Freture is a leading Ball Valve manufacturers in Mumbai, India. They are a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to isolate and control Flow through it.

These are made with high-quality materials and are designed as per API / ASME / ISO / BS standards to withstand high pressures, temperatures, and corrosive applications. We offer a complete range of quarter turn ball valves with different specifications, such as full bore or reduced bore, Flanged Threaded - Butt Weld - Socket Weld, and various Seats Materials (Soft Seated & Metal Seated) to suit process requirements.

Ball Valves are Manual & Automated devices used in Process Piping, a utility to control & isolate the flow of fluids or gases through a pipe. They consist of a hollow ball or sphere with a hole in the middle, which is rotated using a lever or Actuator to control / Isolate the fluid flow.

When the lever or Actuator is turned, the ball inside the valve rotates, either allowing the fluid to flow through the Bore (Orifices) or blocking or Diverting it, depending on the ball's position. The valve can be opened fully, partially, or completely, offering precise control of the fluid flow.

They are commonly used because they are Easy to use, Quick Open & closed, durable, reliable, and require minimal maintenance. They also have a relatively low-pressure drop and can be used in various applications, from low to high-pressure systems.

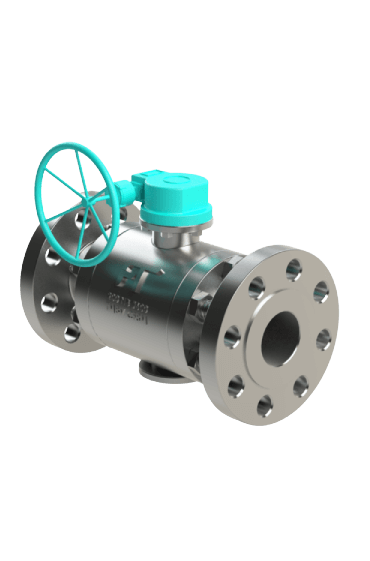

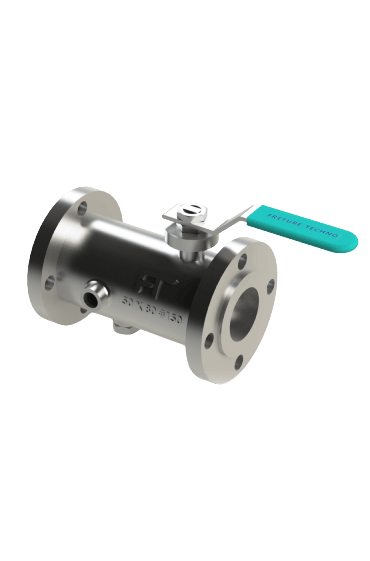

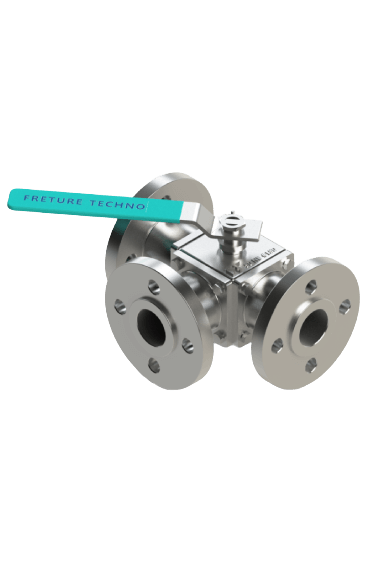

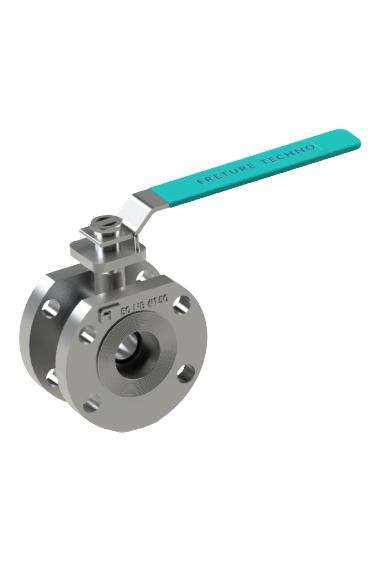

There are different types of Ball Valves available, including Floating & Trunnion Mounted Ball Valve full-port & reduced-port, top-entry & Side Entry, split-body & One Piece, and Two Way, three-way & Four Way Ball valves. These valve used depends on the application and the specific requirements of the system.

Types of Ball Valve

Full-Port : These valves have a full-sized opening, which means that the ball is the same size as the pipe. This results in minimal pressure drop and maximum flow capacity.

Reduced-Port : These valves have a smaller opening than the pipe size, which can result in increased pressure drop and reduced flow capacity. However, reduced-port Ball Valves are often used in applications where a smaller valve size is required.

Top-Entry: These valves are designed with a removable top cover, which makes them easier to service and maintain.

Split-Body: These valves have a two-piece body that allows for easier installation and maintenance.

Three-Way : These valves have three ports instead of two, which allows for more complex flow configurations. Three-way Ball Valves can be used for diverting or mixing fluids.

Trunnion-Mounted : These valves have a fixed trunnion at the top and bottom of the ball, which helps to reduce the torque required to operate the valve.

Floating: These valves have a Floating Ball that is held in place by the compression of the fluid. Floating Ball Valves are typically used in low-pressure applications.

Ball Valve Working

It work by using a hollow ball or sphere with a hole in the middle to control the flow of fluid or gas through a pipe. The ball inside the valve has a hole, or bore, through the center, which is aligned with the pipe when the valve is open.

When the valve is closed, the ball is rotated by a lever or handle so that the bore is perpendicular to the pipe, blocking the flow of fluid. When the valve is open, the ball is rotated so that the bore is aligned with the pipe, allowing fluid to flow through the valve. The ball is typically made of a hard material such as metal and is sealed against the valve body using a seal or gasket. The seal ensures that the valve is leak-proof and prevents the fluid from escaping the system.

They can be either full port or reduced port. Full port Ball Valves have a bore that is the same size as the pipe, which provides a low-pressure drop and high flow capacity. Reduced port Ball Valves have a smaller bore, which can result in increased pressure drop and reduced flow capacity.

They are commonly used because they are reliable, durable, and require minimal maintenance. They can be used in a wide range of applications, from low to high-pressure systems, and are suitable for use with both liquids and gases.

Features:

Durable Construction: They are typically constructed of materials that are resistant to corrosion and wear, such as stainless steel, brass, or bronze. This makes them durable and long-lasting, even in harsh environments.

Easy to Operate: They can be opened or closed quickly and easily using a lever or handle. This makes them ideal for applications where rapid flow control is required.

Tight Shutoff: They provide a tight shutoff when closed, which prevents the leakage of fluids or gases from the system. This is essential in applications where leakage could be dangerous or costly.

Low Torque: They typically require less torque to operate than other types of valves, which means that they can be operated using smaller actuators or handles.

Versatile: They can be used in a wide range of applications, from low to high-pressure systems and with both liquids and gases.

Minimal Maintenance: They require minimal maintenance, as they have few moving parts and do not require lubrication.

Wide Range of Sizes: They are available in a wide range of sizes, from small valves for residential plumbing applications to large valves for industrial processes.

Various Configurations: They can be configured in different ways, such as with full port or reduced port options, top-entry or side-entry design, and different types of end connections.

The industry where these valves used

They are widely used in various industries such as oil and gas, chemical, power generation, and water treatment. They have gained a reputation for reliability, durability, and excellent performance. They are used in many industries where flow control of fluids or gases is required. Some of the industries where these valves are commonly used include:

Oil and Gas: They are used extensively in the oil and gas industry for controlling the flow of oil and gas through pipelines, tanks, and other equipment.

Water and Wastewater Treatment: They are used in water and wastewater treatment plants to control the flow of water, chemicals, and other fluids through treatment processes.

Chemical and Petrochemical: They are used in chemical and petrochemical plants for controlling the flow of chemicals, gases, and other fluids through the manufacturing process.

Power Generation: They are used in power plants to control the flow of steam, water, and other fluids through turbines, boilers, and other equipment.

HVAC and Plumbing: They are commonly used in heating, ventilation, and air conditioning systems, as well as in residential and commercial plumbing applications.

Pharmaceutical and Biotech: They are used in pharmaceutical and biotech applications for controlling the flow of fluids and gases through various stages of production and packaging.

Food and Beverage: They are used in food and beverage processing plants for controlling the flow of fluids, such as water, juice, and other liquids, through the manufacturing process.

Looking for a Trusted Ball Valve Manufacturer in India?

Whether you need a custom-engineered floating ball valve, a fire-safe trunnion-mounted design, or high-pressure forged ball valves, Freture Techno Pvt. Ltd. delivers. We are proud to be one of the most respected Ball valve manufacturers in Mumbai, India, serving clients across domestic and international markets

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Ball Valve?

- How does it work?

It operates by rotating a spherical disc (the ball) inside the valve body. When the handle is turned perpendicular to the pipe, the valve is closed, and when it's parallel, the valve is open, allowing fluid to flow through.

- What are the main applications?

It is used in various industries such as oil and gas, chemical processing, water and wastewater treatment, HVAC systems, and residential plumbing. It is suitable for applications requiring efficient shut-off and control of flow.

- What are the benefits of using one?

Benefits include reliable sealing, quick operation, minimal pressure drop, excellent flow control, durability, and suitability for a wide range of temperatures and pressures.

- What materials are used in their construction?

It can be made from a variety of materials including stainless steel, brass, bronze, cast iron, and various plastics such as PVC, CPVC, and PTFE, with the choice depending on the application's requirements.

- How do I choose the right one for my application?

Consider factors such as the type of fluid, pressure and temperature conditions, flow rate, pipe size, end connections, and the specific requirements of your system to select the appropriate Ball Valve.

- Can they be repaired?

Yes, It can be repaired, typically by replacing the worn or damaged components such as the seals, seats, or ball. However, this depends on the extent of damage and the valve's design.

- What maintenance is required?

Regular inspection and lubrication of moving parts are essential for maintaining optimal performance. Additionally, periodic testing for leaks and checking for any signs of wear or corrosion is recommended.

- Are they available in different designs?

Yes, It come in various designs including two-way, three-way, and multi-port configurations, as well as different end connections such as threaded, flanged, and welded.

- Why is Freture the best place to buy Ball Valves from?

Freture offers high-quality Ball Valves made from superior materials, a wide selection of designs to meet diverse needs, expert support for optimal valve selection, competitive pricing, and excellent after-sales support and warranty services.

Industries where Ball Valve is Used

Oil and Gas Industry

Chemical Processing

Wastewater Management

HVAC

Petrochemical Industry

Applications of Ball Valve:

- Isolation: They are commonly used for on/off control and isolation of fluid flow in pipelines.

- Flow Control: They are ideal for precise flow control due to their quarter-turn operation, making them suitable for throttling applications.

- High Pressure and Temperature: They are suitable for high-pressure and high-temperature applications, including in oil and gas pipelines and steam systems.

- Versatile Usage: Widely employed in various industries such as oil and gas, chemical processing, water treatment, and HVAC.

- Quick Operation: They offer quick and reliable operation, making them suitable for emergency shut-off and critical processes.