A Limit Switch Box is a device used for monitoring the position of valves in industrial settings. It provides feedback on the open and closed positions of valves, ensuring precise control and monitoring of critical processes.

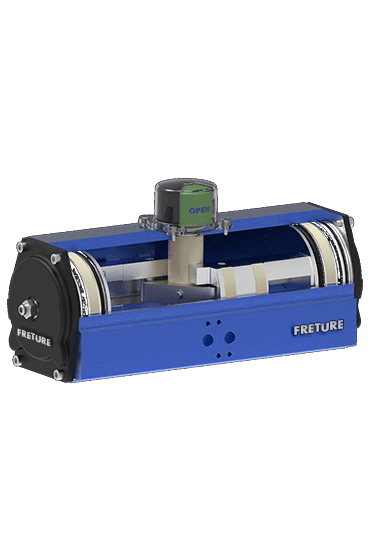

Limit Switch Box

It is an easy and precise cam set with zero requirements for a setting tool.

We are a leading manufacturer of Valve Limit Switch Box in Mumbai, India. Limit Switch has a unique and user-friendly design and is one of its kind in the industry. It fits best for quarter-turn and applications in extreme environments. The design avoids any wrong assembly of the box onto the valve, ensuring a fail-safe system. Additionally, the limit switch comes with UV and corrosion resistance, plus an inner ABS indicator.

With a focus on quality and performance, our Limit Switch Boxes ensure precise and repeatable switching, guaranteeing optimal control and safety in industrial processes. Designed to withstand harsh operating conditions, limit switch for valves offer long-lasting durability and consistent performance. Trust Freture Techno as your preferred partner for top-quality limit switch box for pneumatic actuator, delivering unparalleled reliability and performance.

Description | Features |

|---|---|

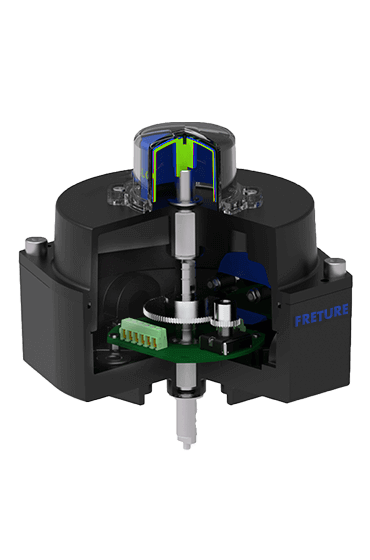

Switch Type : Mechanical / Flat Inductive / Cylindrical / Slot Inductive Inductive Switch Model : Honeywell/Crouzet/IFM/Turck/Pepperl+Fuchs Cable entry sizes : 1/2" NPT, 3/4" Cable entries : 2(max 4) Temperature Range : -20°C to +125°C Body Materials : ALUMINIUM PRESSURE DIE CAST Communication Protocols : HART / Mod Bus Profibus Etc Voltage Rating : 24V DC Monitoring Signal : 4-20mA analog signal Weatherproof: IP65 as standard / IP67 available Certification : IP 66/IP 68 / CE marking / Ex d/ RoHs | Modular Construction : Rugged PCB design ensures durability with Customization / Modifications. Multiple Actuators: Integration with various types of actuators and sizes. Compact Design: Space-saving, easy integration. Visual Indicators: LED indicators for quick status checks. Longetivity: corrosioin free with minimal maintenance Build Industrial Compatibility : Consistent power supply In every Industry. Monitoring : Allows monitoring of valve position via analog signals. Zero Down Time : Easy and Mulitple access terminal points for use. Weatherproof: Resistant to dust, moisture, and other environmental factors. |

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Limit Switch Box?

- How does it work?

It works by detecting the position of the valve actuator. When the actuator reaches a specific position, it triggers the limit switch inside the box, sending a signal to the control system to indicate the valve's status.

- What are the main applications?

They are widely used in various industries such as oil and gas, chemical processing, water treatment, power generation, and pharmaceuticals. They are applied in valve automation systems to ensure accurate positioning and control.

- What are the benefits of using one?

The benefits of using a Limit Switch Box include precise valve position monitoring, enhanced process control, improved safety, reduced downtime, and increased operational efficiency.

- What materials are used in their construction?

They are typically constructed from durable materials such as stainless steel, aluminum, and high-strength plastics. These materials ensure reliability and longevity even in harsh industrial environments.

- How do I choose the right one for my application?

Choosing the right Limit Switch Box involves considering factors such as the type of valve, environmental conditions, required signal output, and compatibility with the control system. Our technical experts can assist in selecting the most suitable option for your specific application needs.

- Can they be repaired?

Yes, It can often be repaired. Maintenance and repair may involve replacing faulty components, adjusting settings, and ensuring proper calibration to restore functionality.

- What maintenance is required?

Regular maintenance of Limit Switch Boxes typically includes inspection, cleaning, and lubrication of moving parts. It's essential to ensure proper functioning and extend the lifespan of the device.

- Are they available in different designs?

Yes, Limit Switch Boxes are available in various designs to accommodate different valve types and installation requirements. These designs may include different enclosure types, mounting options, and electrical configurations.

- Why is Freture the best place to buy from?

Freture is the best place to buy Limit Switch Boxes due to our commitment to providing high-quality products, expert technical support, competitive pricing, and exceptional customer service. Our Limit Switch Boxes are designed and manufactured to the highest industry standards, ensuring reliability, durability, and performance in diverse industrial applications.

Industries where Limit switch Box is Used

Oil and Gas Industry

Chemical Processing Industry

Water and Wastewater Treatment Industry

Power Generation Industry

Pharmaceutical Industry

Application of Limit Switch Box

Valve Position Monitoring: They are used to monitor the open and closed positions of valves in various industrial applications, ensuring accurate valve position feedback.

Process Control: They play a crucial role in process control by providing signals for valve actuation, allowing for precise control over fluid flow and pressure regulation.

Safety Systems: They are integrated into safety systems to detect and signal the position of critical valves, facilitating timely responses during emergency shutdowns or abnormal operating conditions.

Automation Systems: They are essential components of automation systems, providing feedback to control panels for automated valve operation, reducing the need for manual intervention and enhancing operational efficiency.

Fault Detection: They are utilized for fault detection in valve operation, alerting operators to any malfunctions or deviations from the expected valve positions, thereby ensuring smooth and reliable industrial processes.