Lined tee are pipe fittings with an internal lining, typically made from materials like PTFE (Polytetrafluoroethylene) or PFA (Perfluoroalkoxy), designed to protect the underlying metal from corrosion and chemical attack. They are used in systems where the conveyed fluids are highly corrosive or where high purity is required.

PTFE Lined Tee Manufacturer

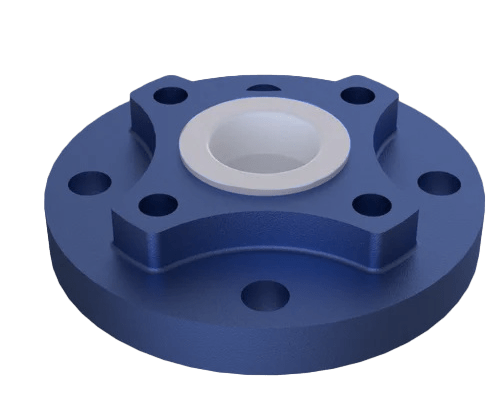

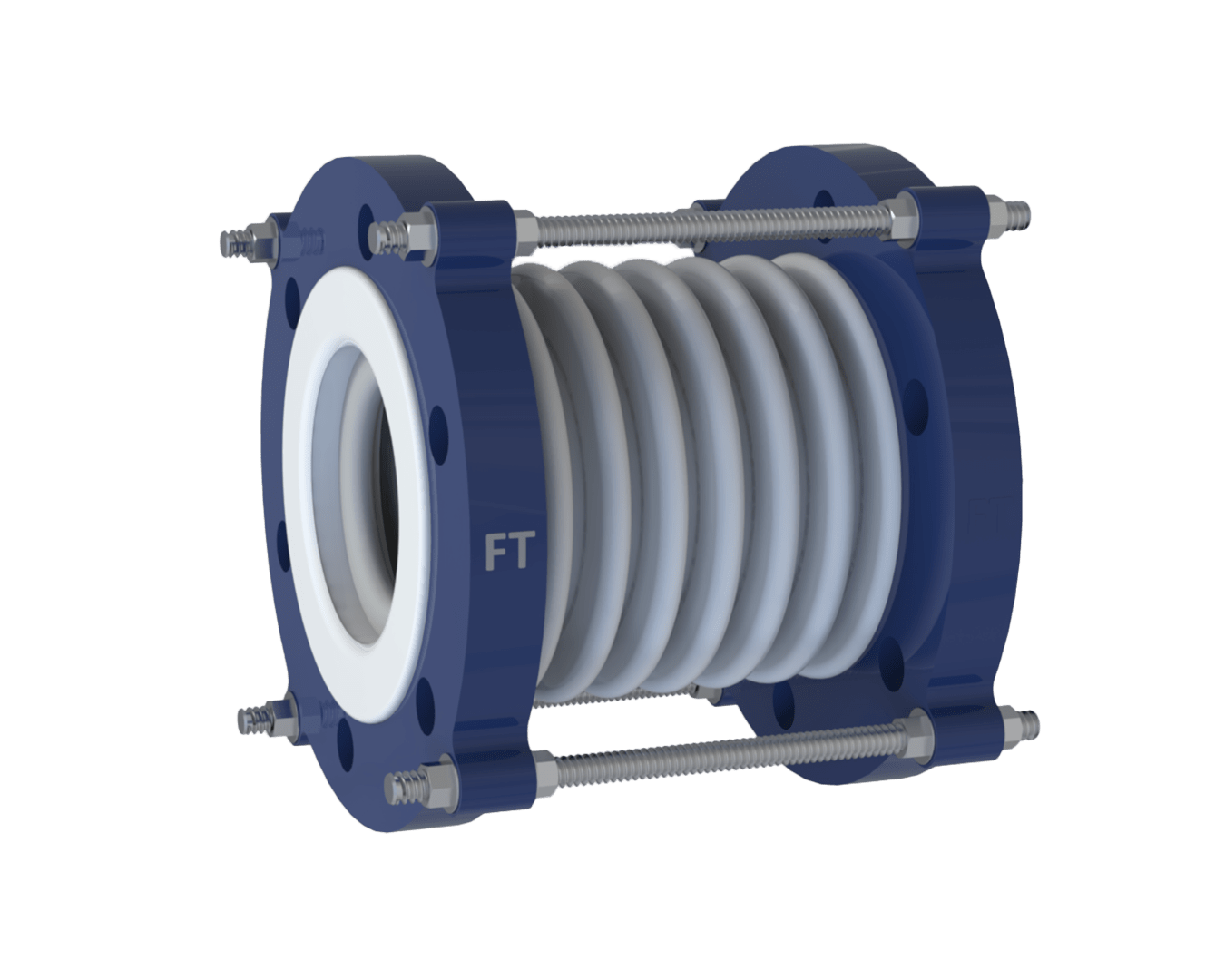

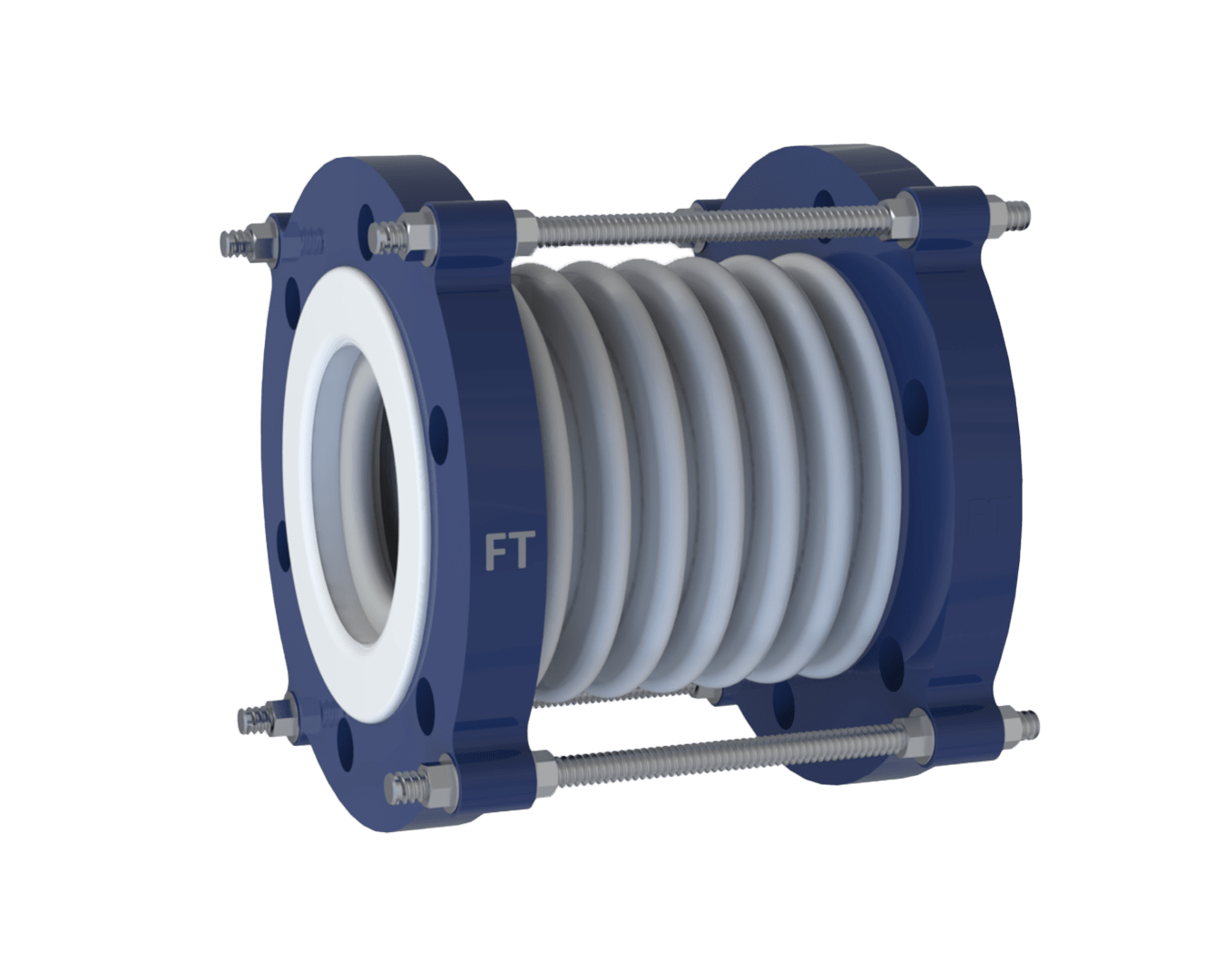

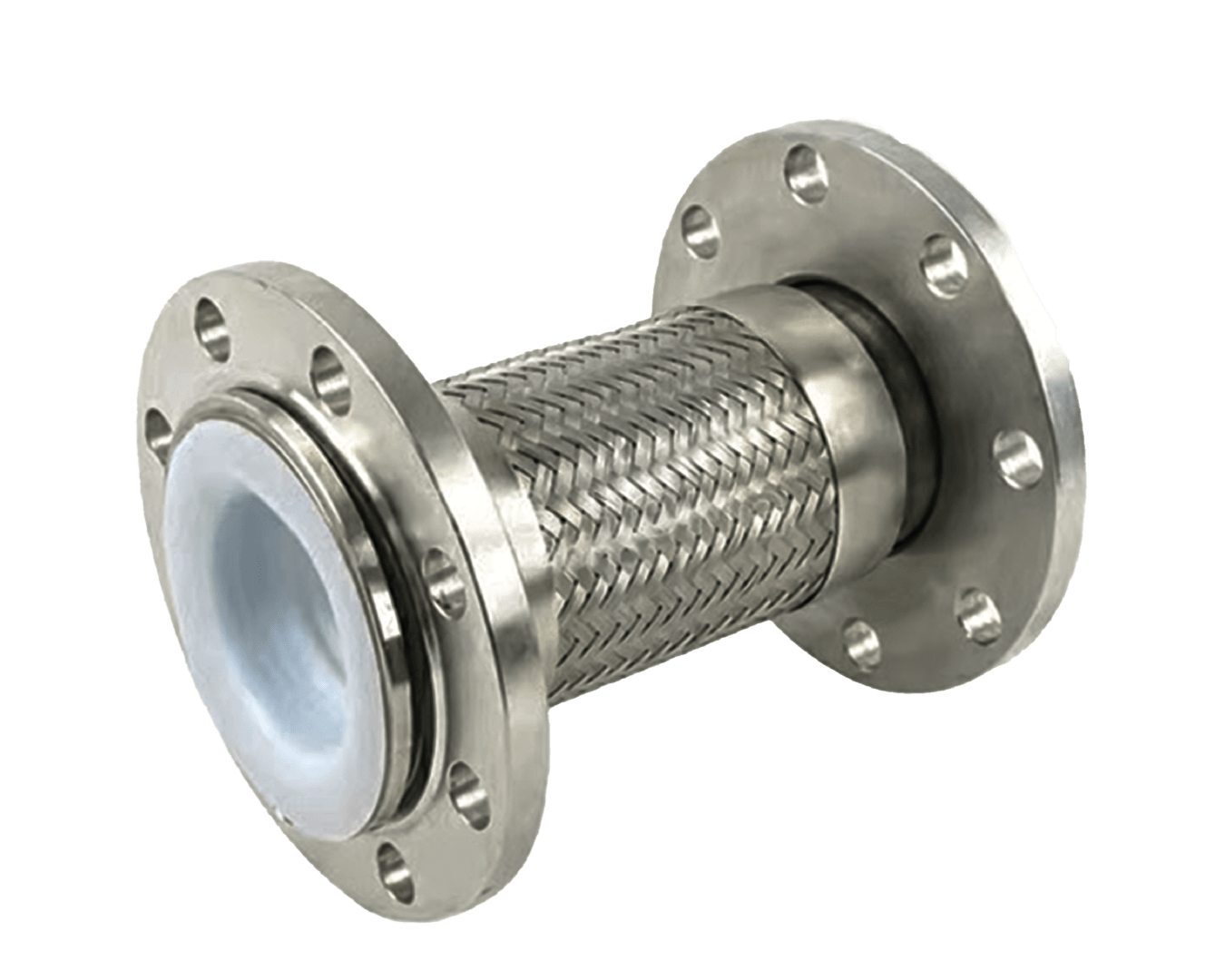

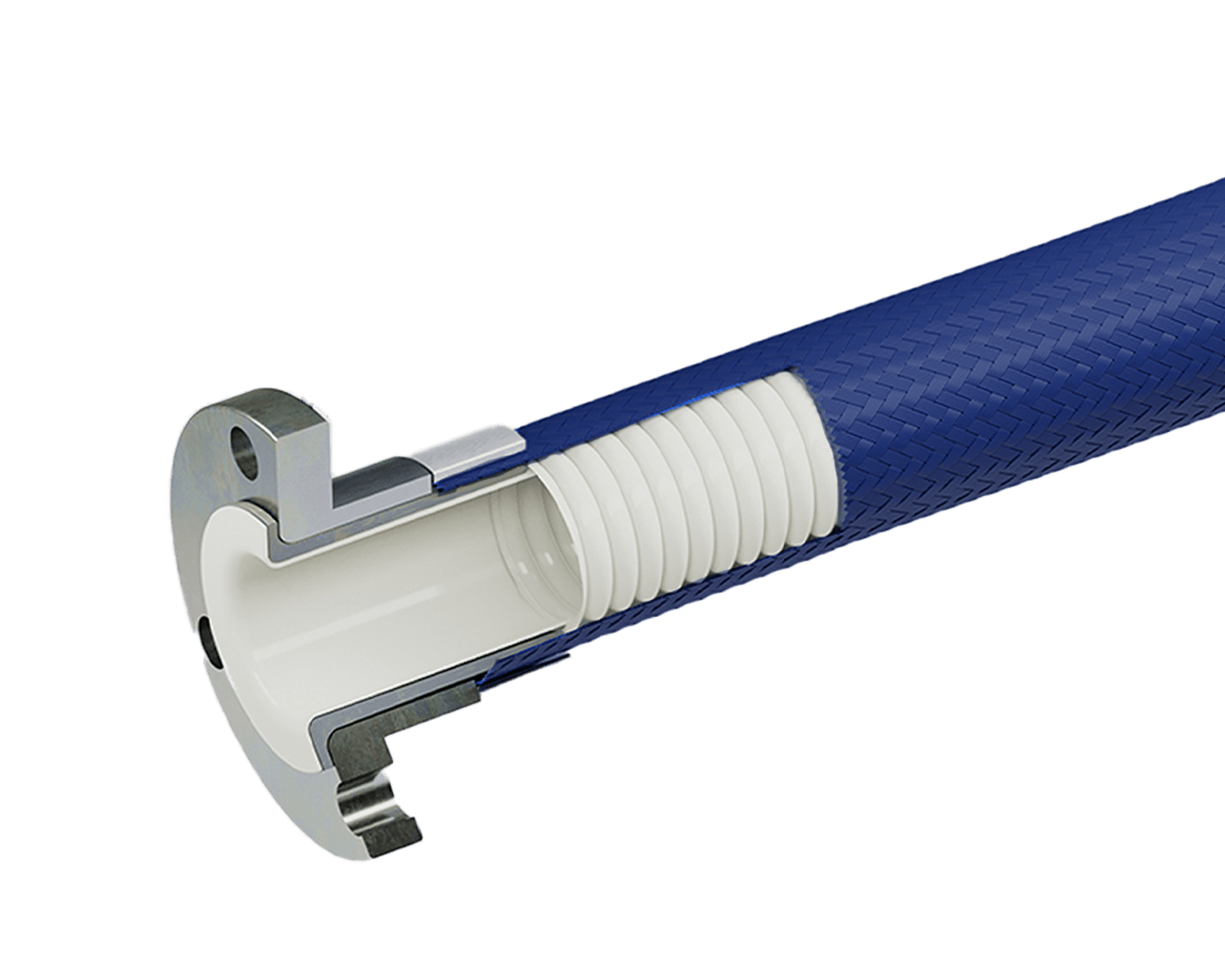

A PTFE Lined Tee is a specialized pipe fitting designed to connect three sections of piping, facilitating the distribution or redirection of fluids within industrial systems. Its internal lining, made from materials like polytetrafluoroethylene (PTFE), provides a smooth, corrosion-resistant surface that enhances flow efficiency and protects the SS tee from aggressive chemicals.these are Available in different Types & sizes, including Equal tees, reducing tee, and PTFE Lined Instrument tee, each serving specific functions in fluid distribution systems for all possible connections. This makes it indispensable in industries such as petrochemicals, pharmaceuticals, and food processing, where maintaining the purity of substances and ensuring system longevity are paramount.

The working mechanism of a Teflon Lined Tee involves channeling fluids through its main run and branch outlets. Commonly used materials include carbon steel, SS 316L (stainless steel), and various alloys, which are then lined with corrosion-resistant materials like PTFE, PFA, or FEP. This smooth design minimizes the risk of contamination and corrosion, thereby reducing maintenance requirements and prolonging the lifespan of the piping system.The non-conductive properties of the PTFE also provide electrical insulation, making it suitable for applications involving conductive fluids Best suit for Semiconductor industry.

Incorporating PFA / FEP / PTFE lined tees into industrial piping systems offers key benefits. Equal tees ensure uniform flow distribution, reducing tees connect pipes of varying sizes, and instrument tees provide secure points for instrumentation. The anti-leak properties of the PTFE lining reduce leaks and system failures, enhancing safety. With an extended lifespan, these require fewer replacements, minimizing waste and supporting sustainable practices. By optimizing flow efficiency and reducing maintenance, PTFE lined tee contribute to cost-effective and eco-friendly operations.

Specifications | Features |

|---|---|

Type: Lined Equal Tee, Lined Reducing Tee, Lined Instrument Tee Design Standards: ASME B16.5, DIN EN 1092 Size Range: 25 NBto 300 NB End Connections: Flanged ASME B16.5, ANSI B16.42 M.O.C.: Steel Fabrication (ASTM A234 Gr. WPB), Ductile Iron (GGG40.3 / ASTM A395), Cast Steel (ASTM A216 Gr. WCB), Stainless Steel (ASTM A312 TP304 / 316, SCH.-40) Lining Material: PTFE (ASTM D4895), PFA (ASTM D 3307), FEP (ASTM D 2116), PVDF (ASTM D 3322), PP (ASTM D 4101) Lining Thickness:3 mm to 6 mm Conductivity: 0.20 to 0.6 W/mK Coefficient Of Friction : 0.05 to 0.10 Hydraulic Test: 29 Kg/cm² Spark Test: 20 K.V.D.C

|

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What are PTFE lined tee, and why is it used in piping systems?

- How do Lined Tee compare to the standard in terms of cost and performance?

Lined PTFE tees are generally more expensive than Metal ones such as MS / CS / SS tees due to the cost of the lining materials and the manufacturing process. However, their enhanced durability and resistance to corrosion can lead to cost savings over time by reducing maintenance and replacement needs.

- How do Unequal / Reducing tee differ from Equal tee in lined piping systems?

Lined Reducing tees have one inlet and two outlets of different sizes, allowing for a branch connection with varying pipe diameters. In contrast, equal tees have three outlets of the same size, forming a 90-degree branch connection.

- What materials are commonly used for lining tees, and what are their properties?

Common lining materials include PTFE and PFA. PTFE lining offers excellent chemical resistance and high-temperature stability, while PFA provides similar chemical resistance with enhanced flexibility, making it suitable for tubing applications.

- How is a PTFE tee installed in a piping system?

Installation involves connecting the lined PTFE tee to adjacent pipes using flanged or welded joints, depending on the system design. It's crucial to ensure that the lining is not damaged during installation to maintain its protective properties.

- How do lined Equal tee enhance the lifespan of piping systems?

The Teflon lining acts as a barrier, preventing direct contact between the corrosive fluid and the metal substrate. This significantly reduces the risk of corrosion, erosion, and chemical degradation, thereby extending the service life of the piping system.

Industries where PTFE Tee is Used

Chemical Processing Industry

Water Treatment Industry

Power Generation Industry

Pharmaceutical Industry

Food & Beverage Industry

Application

- Acid Handling: Used in piping systems that transport concentrated acids, preventing corrosion and extending the lifespan of the infrastructure.

- Solvent Transfer: They facilitate the safe transfer of organic solvents, ensuring that the piping system remains intact and free from chemical degradation.

- Pharmaceutical Manufacturing: Utilized in the production of pharmaceutical compounds, where purity and resistance to chemical reactions are critical.

- Chemical Injection Points: facilitate the injection of chemicals into steam lines, preventing corrosion and scaling within the system.

- Flue Gas Desulfurization: They are used in systems that treat flue gases, handling aggressive chemicals without compromising the piping infrastructure.

- Cooling Tower Systems: Integral in the distribution of water within cooling towers, ensuring efficient heat exchange and system longevity.

- Active Ingredient Synthesis: Used in the synthesis of active pharmaceutical ingredients (APIs), where they handle corrosive chemicals without compromising the system.