Lined Reducing Flange typically features linings made from teflon materials such as PTFE, FEP, PFA or PVDF. The choice of lining material depends on factors like chemical compatibility, temperature, and pressure requirements.

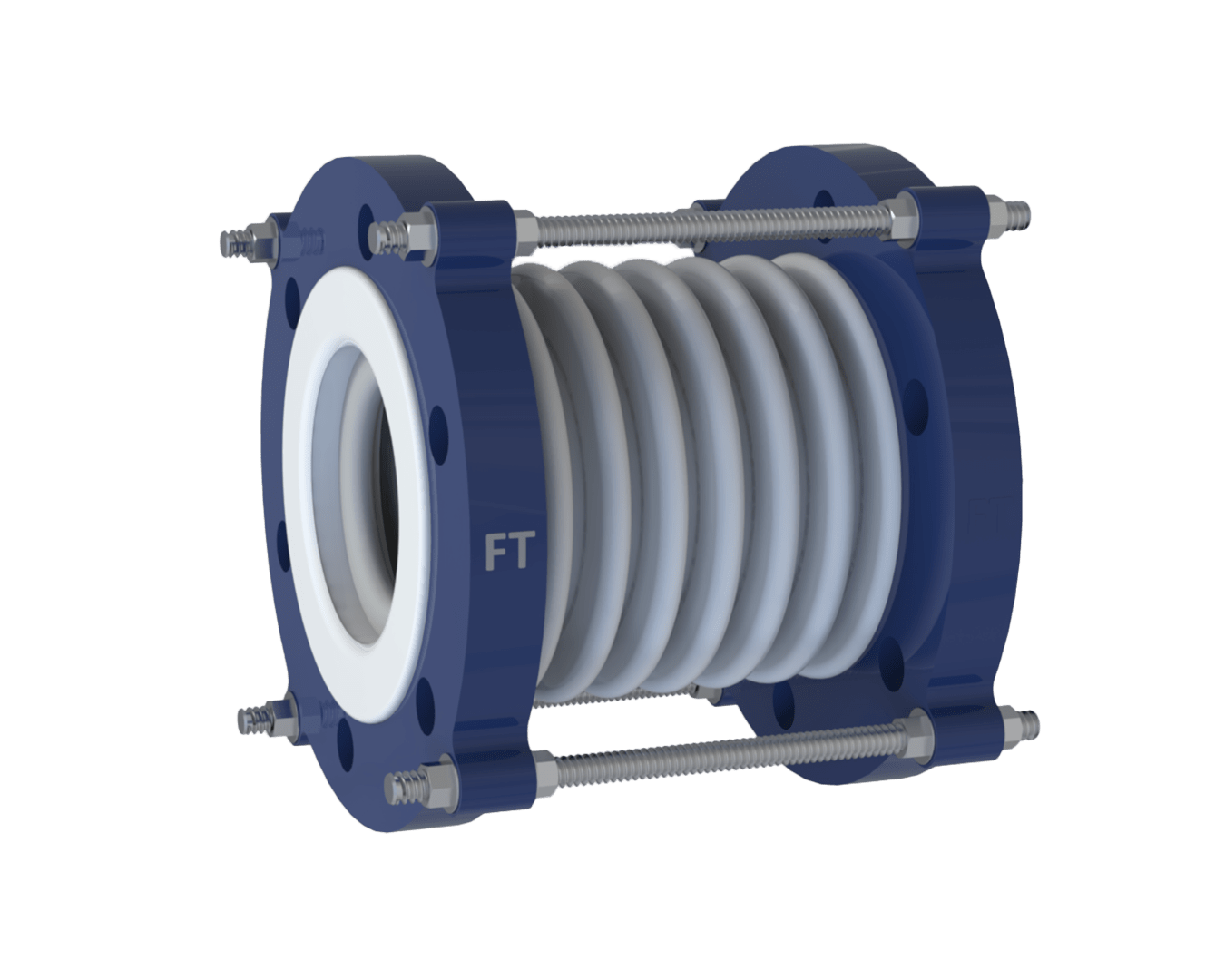

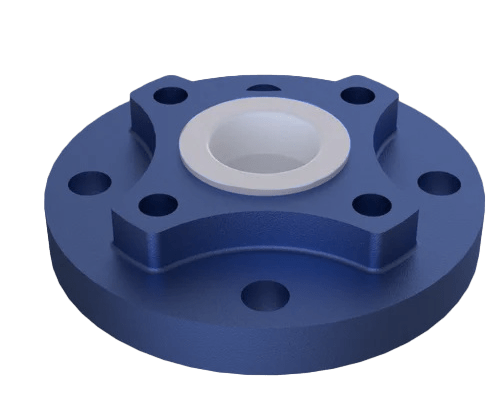

PFA / PTFE Lined Reducing Flange

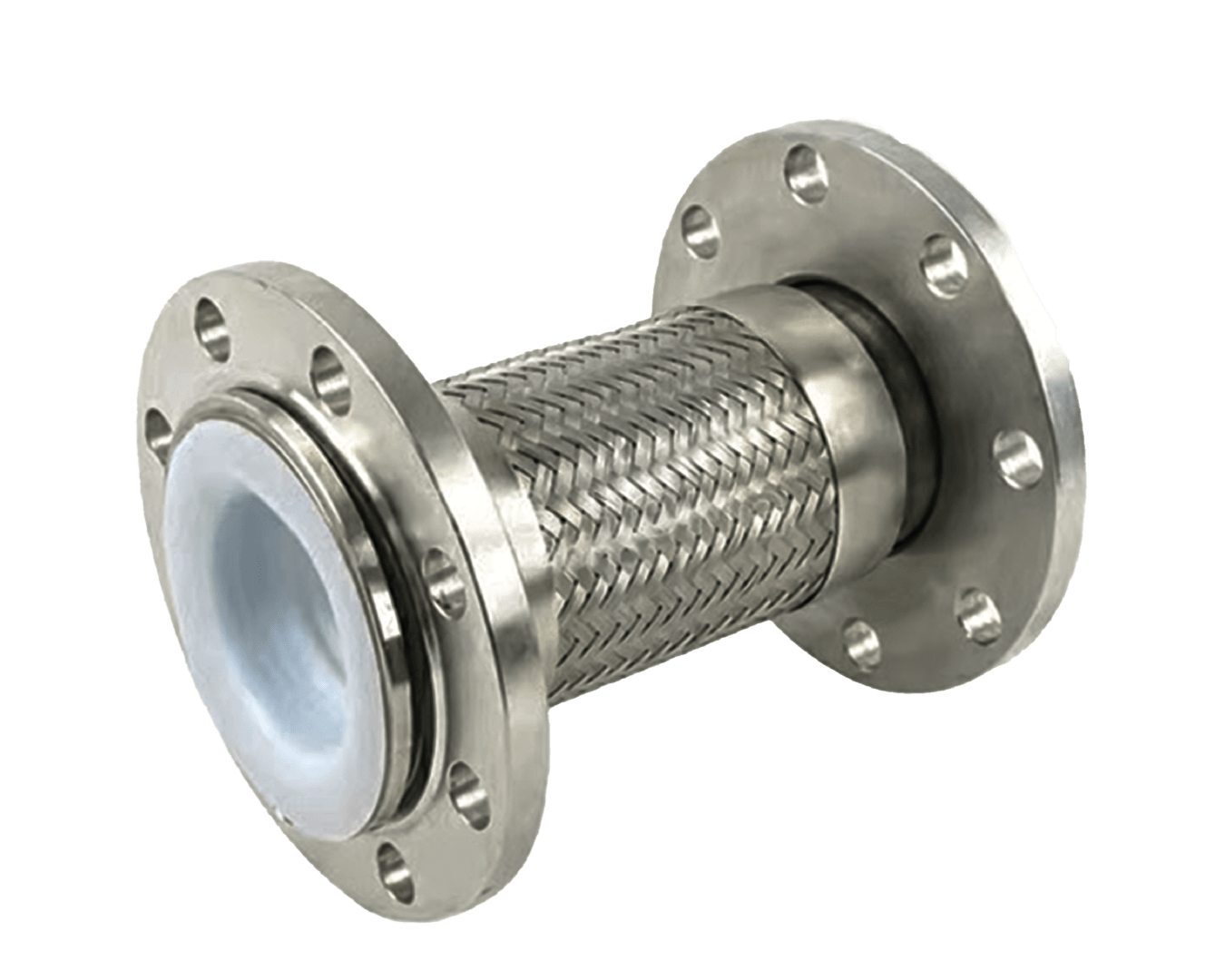

Freture Techno's PFA / PTFE Lined Reducing Flange are meticulously Manufactured to facilitate seamless transitions between pipes of varying diameters carrying Harsh Media without corrosion and leak. By maintaining a consistent flow path, Reducer flanges minimize turbulence and pressure loss, ensuring peak system performance. Available in concentric and eccentric designs, they offer precise control over the reduction process, accommodating specific pipeline configurations in industries such as chemical processing, pharmaceuticals, Food & beverages and power generation, where the safe transport of corrosive substances is critical.

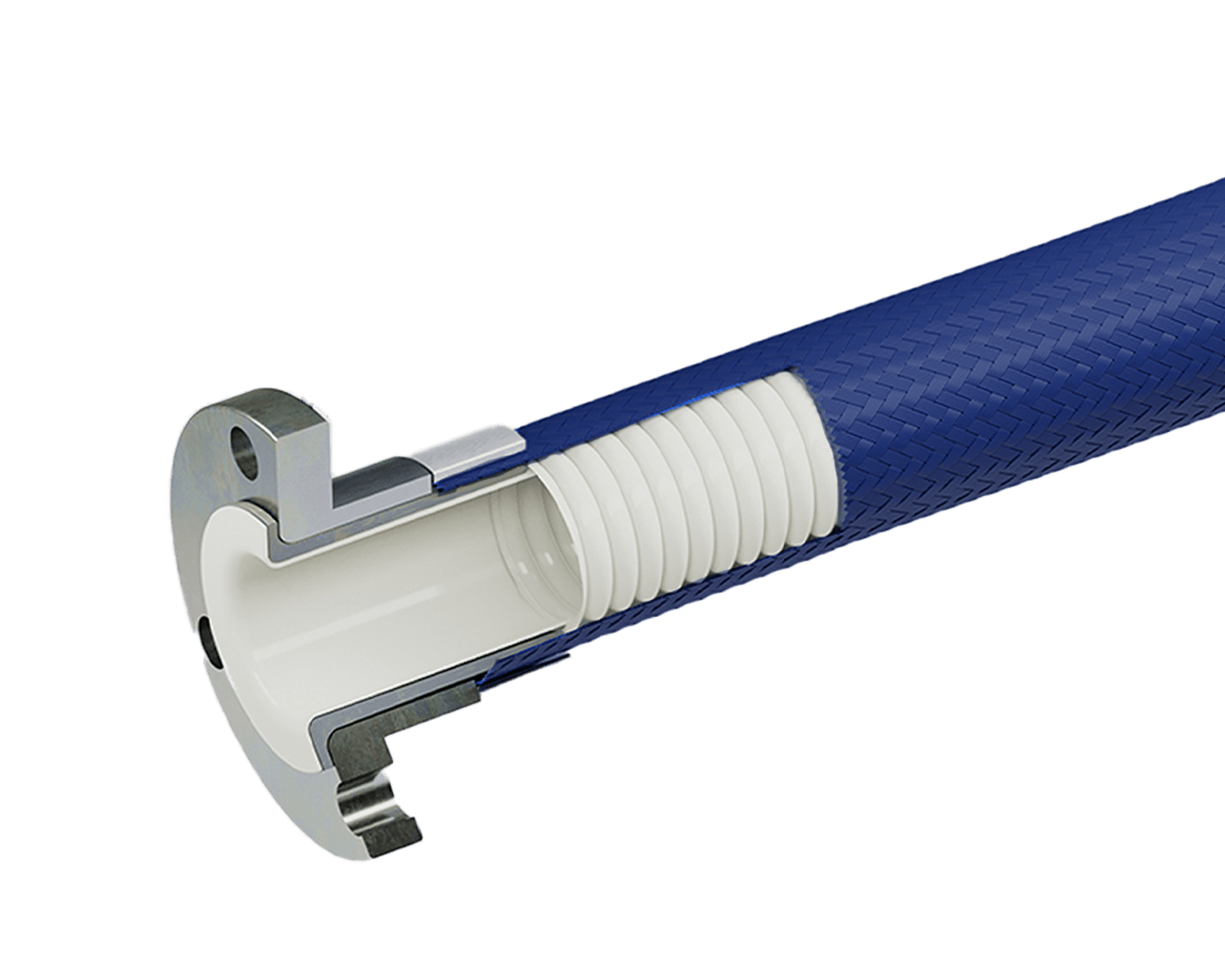

A standout feature of this Teflon Lined Reducing Flange is their high-quality linings, crafted from materials such as PTFE / FEP / PVDF / PFA. These linings serve as robust barriers against aggressive chemicals, protecting the flange's corrosive metal body and connected equipment from corrosion. With a lining thickness of 3.5 mm (6.0 mm overall), they are built for durability and consistent performance, even in extreme environments. The smooth interior surface provided by the linings reduces friction, enabling efficient flow and contributing to energy savings and lower operational costs.

In industries like pharmaceuticals and chemical processing, where handling corrosive substances is routine, these PFA / PTFE Lined Reducing Flange is indispensable. Their chemical resistance ensures system integrity, while the non-stick properties prevent material buildup, reducing maintenance requirements. By extending the lifespan of equipment and lowering long-term maintenance expenses, Lined flanged Reducer contributes to sustainability by minimizing resource consumption and waste generation, aligning with environmental and economic goals.

Specifications | Features |

|---|---|

Size Range: 15NB to 300NB (custom sizes available) Temperature: -29°C to 200°C Types: Lined Reducing Flange Flange Standard: ANSI B16.5 / B16.42 Material: ASTM A234 Gr. WPB, DI A395, SS304, SS316 Flange Material: ASTM A105 (N), IS 2062, ASTM A351 Gr. CF8 & CF8M Lining Standard: ASTM F1545 Lining: Moulded FEP, PFA Lining Options: PTFE (ASTM D4895), PFA (ASTM D 3307), FEP (ASTM D 2116), PVDF (ASTM D 3322), PP (ASTM D 4101) Lining Thickness: Minimum 3.5 mm / 6.0 mm overall (±1.0 mm tolerance) Lining Spark Test: 20 KVDC after lining

|

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What materials are commonly used for the lining in PTFE Lined Reducing Flange?

- How do I select the appropriate lining material for my application?

Selecting the right lining material involves evaluating the chemical properties of the fluids being transported, operating temperatures, and system pressure. Consulting with manufacturers or material compatibility charts can aid in making an informed decision.

- Is this Teflon PTFE Lined Reducing Flange compatible with different flange standards?

Yes, PTFE flange can be manufactured to comply with various standards, including ASA 150#, ASA 300#, DIN, and JIS 10K, ensuring compatibility with different piping systems.

- How does the lining thickness affect the performance of reducing flange?

Lining thickness, typically ranging from 3 to 6 mm, plays a vital role in providing corrosion resistance and durability. Adequate thickness ensures a longer service life and better protection against aggressive media.

- What quality control measures are essential in the manufacturing of reducing flange?

Key quality control measures include verifying resin conformity to ASTM standards, conducting hydraulic tests (e.g., at 29 Kg/cm² after lining), and performing spark tests (e.g., at 15 KV D.C after lining) to detect lining defects.

- What are the common challenges in sourcing high-quality PTFE Lined Reducing Flange?

Challenges include ensuring dimensional accuracy, verifying material quality, and confirming that the flanges meet industry standards. Partnering with reputable manufacturers who adhere to stringent quality control processes can mitigate these issues. Freture is one of the highest quality flange manufacturers known for their Stringent products and expert service.

- How do lined reducing flange contribute to cost savings in piping systems?

By providing a reliable method to connect pipes of differing sizes with corrosion-resistant linings, PTFE reducing flange minimises the need for additional fittings and maintenance, leading to reduced installation and operational costs.

Industries where Lined Reducing Flange is Used

Pharmaceutical Industry

Chemical Industry

Food and Beverage Industry

Water Treatment Plants

Power Generation Industry

Application

- Acid Processing Lines: Connecting pipes of varying sizes in systems transporting strong acids like sulfuric or hydrochloric acid.

- Caustic Soda Production: Integrating different diameter pipes in the production process of sodium hydroxide, ensuring safe and efficient flow.

- Flue Gas Desulfurization Units: Joining pipes in systems that remove sulfur dioxide from exhaust gases.

- Chemical Dosing Lines: Connecting pipes of different sizes that add coagulants and disinfectants to water.

- Purified Water Systems: Connecting pipes of different sizes in systems supplying high-purity water for drug formulation.

- Beverage Production Lines: Connecting pipes of varying sizes in the processing and bottling of drinks like juices and soft drinks.