PTFE lining offers exceptional resistance to corrosion, chemicals, and wear to both the Concentric And Eccentric Reducer. It provides a smooth, non-stick surface that prevents scale buildup, reduces friction, and ensures a longer lifespan of the equipment, making it ideal for handling aggressive fluids in critical applications.

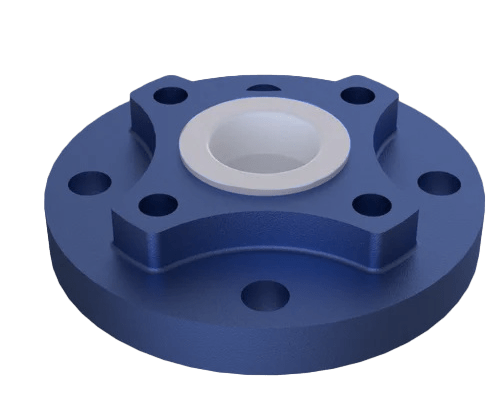

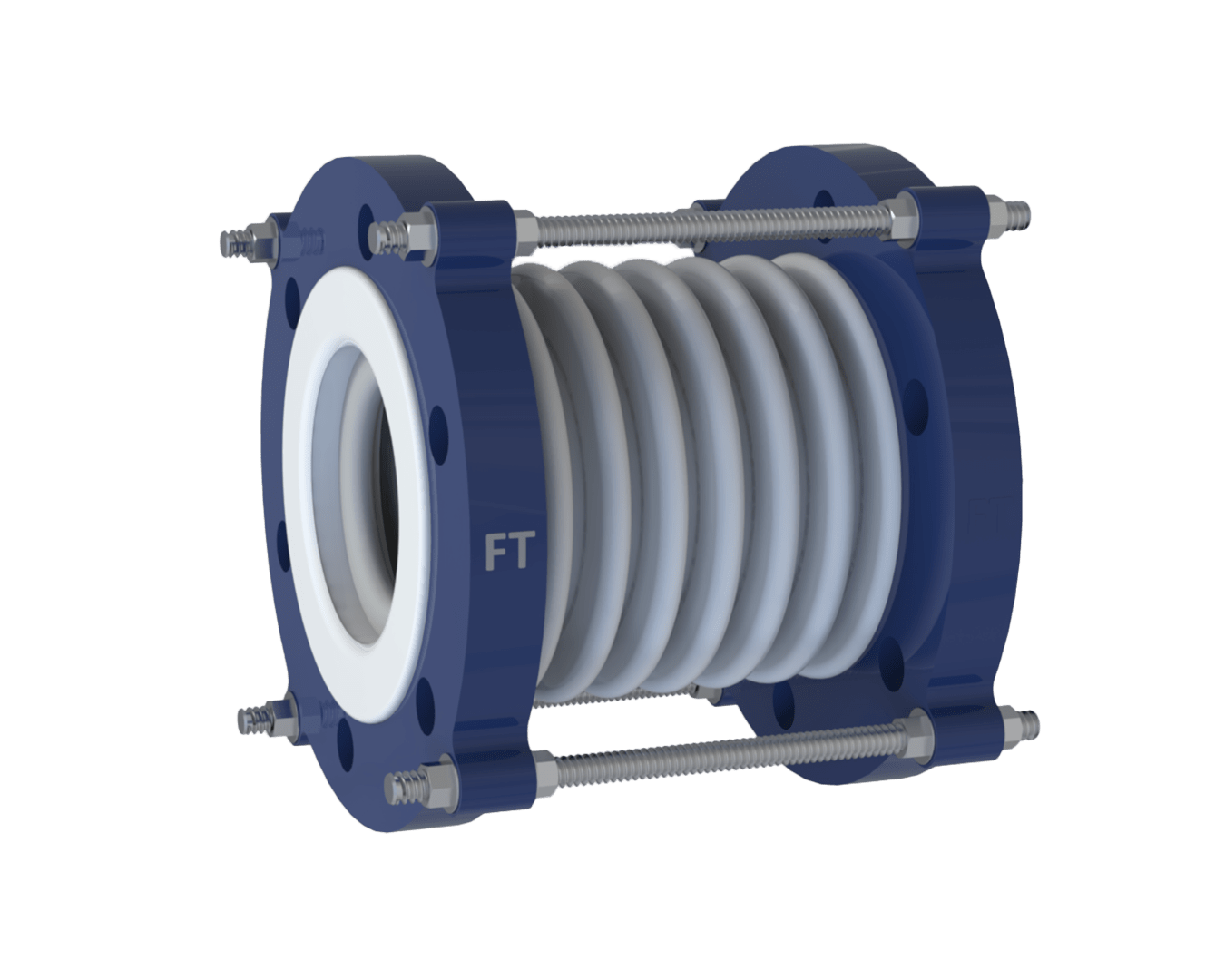

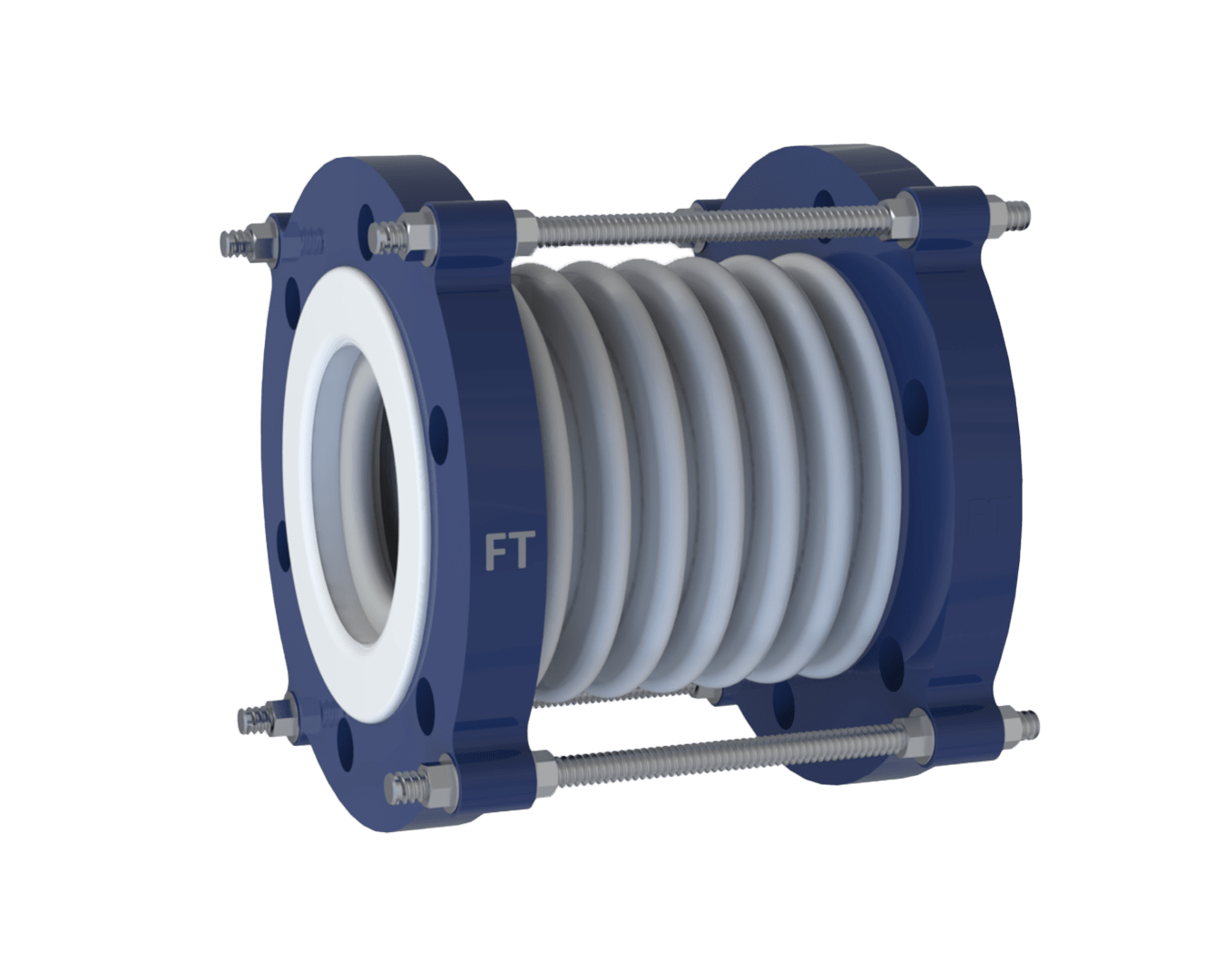

PFA / PTFE Lined Concentric Reducer

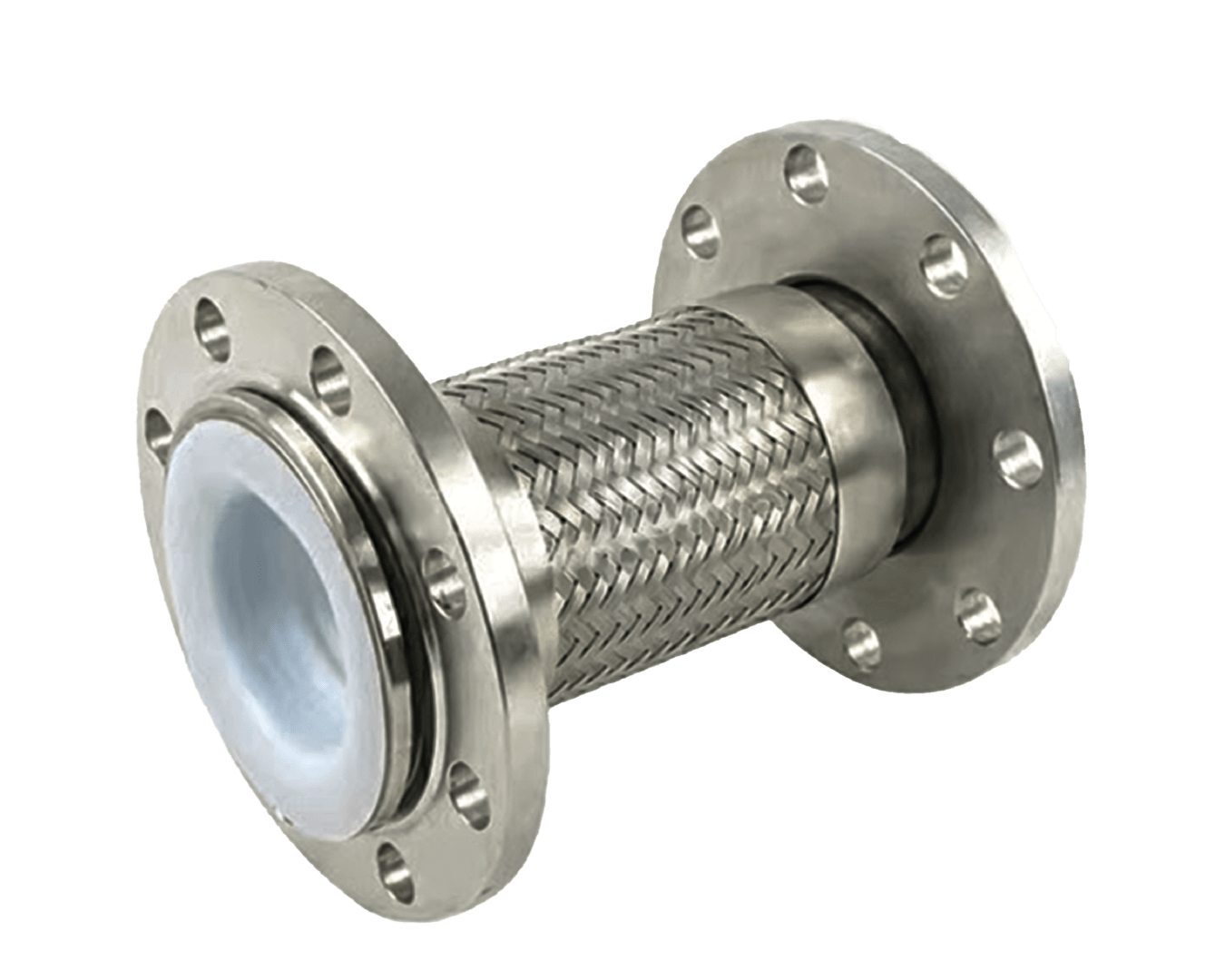

Freture’s PTFE / PFA Lined Concentric and Eccentric Reducer are manufactured in Mumbai, India.These Reducers are designed to reduce the pipe size (15 mm to 300 mm) smoothly while maintaining flow efficiency and reducing system pressure. The Teflon Lining material selection for the fluorocarbon lining is based on the specific operating conditions of the fluid, ensuring compatibility and superior protection. These Reducers are available in both eccentric and concentric types, catering to diverse requirements. Ideal for high chemical and mechanical resistance, especially in industries such as pharmaceuticals, chemicals, and water treatment.

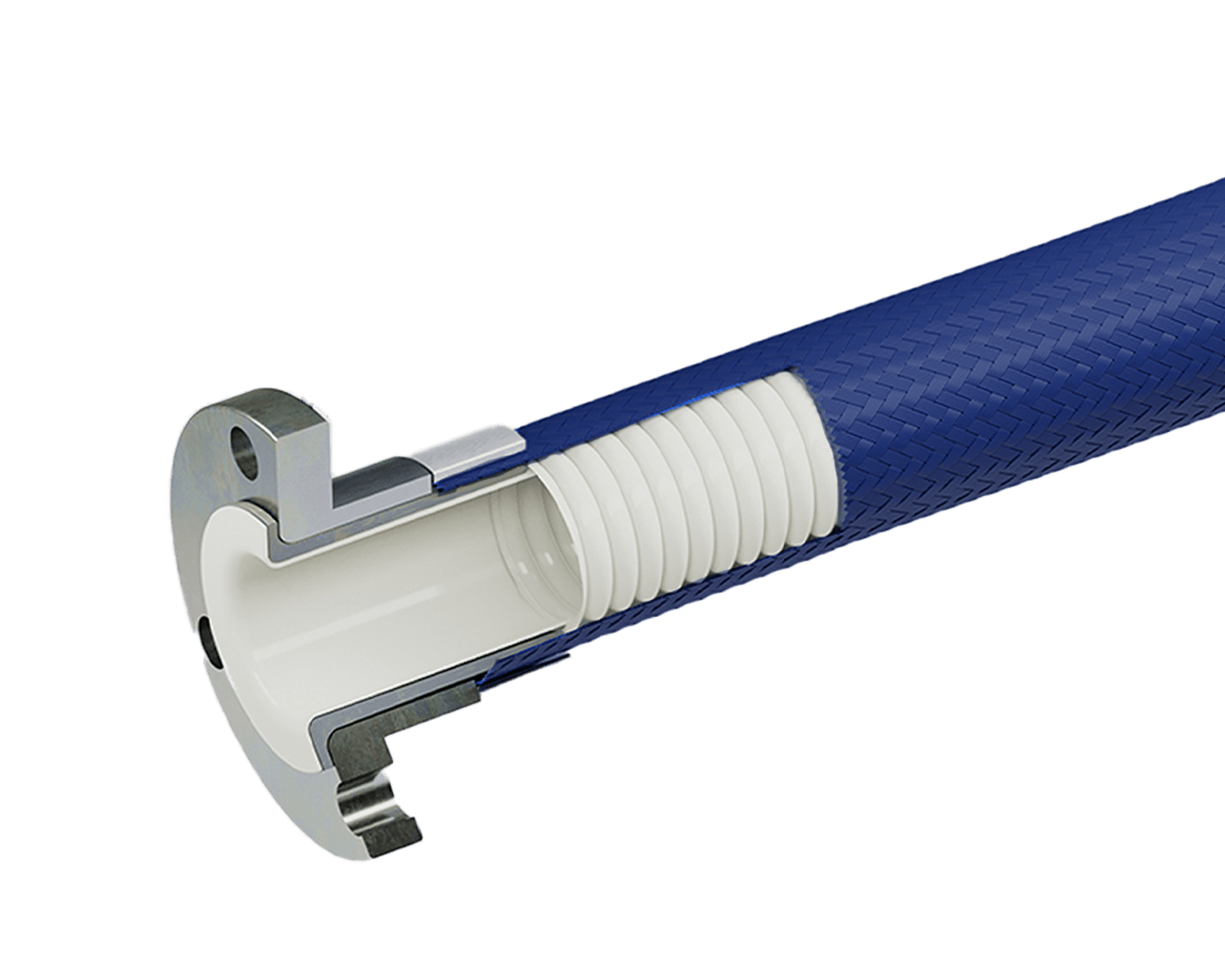

PTFE / PFA Lined Reducer comes with PTFE or PFA lining over high-quality materials such as Ductile Iron, Cast Steel, and SS 304/ SS 316 to handle high pressure and temperature. PFA / PTFE Reducers offer exceptional performance across a wide range of applications, providing reliable protection against corrosion zero pressure drop due to less friction while transitioning between different pipe sizes. The 3 mm to 6 mm thick PTFE lining guarantees that these Reducers withstand harsh chemical environments and offer longevity in even the most demanding conditions. The leak-free design of lined tees is achieved through precise manufacturing processes that ensure a seamless bond between the lining and the base material, preventing leaks and enhancing the overall reliability of the piping system.

Lined Concentric Reducers are flanged at each end and are primarily used in vertical piping systems. Lined Eccentric Reducers, flanged in the same way, are made for use in horizontal piping, where the flat section through the reducer helps to prevent pooling of liquid in the piping. This design ensures efficient fluid handling, even in varying pressure and flow conditions. Whether used with Different Pipe, combined Reducers, or reducing flanges, these PTFE Reducers provide smooth transition, optimizing flow efficiency and minimizing pressure loss. Moreover, the long-lasting nature of PTFE Lined Concentric Reducer reduces the need for frequent replacements, leading to fewer materials used and less waste generation.

Specifications | Features |

|---|---|

Design Standards: ASME B16.5, DIN EN 1092 Size Range: 25 mm to 300 mm Type: Lined Concentric Reducer, Lined Eccentric Reducer Temperature Range: -30°C to +230°C Construction Material: Steel Fabrication (ASTM A234 Gr. WPB), Ductile Iron (GGG40.3 / ASTM A395), Cast Steel (ASTM A216 Gr. WCB), Stainless Steel (ASTM A312 TP304 / 316, SCH.-40) End Connections: ASME B16.5, ANSI B16.42 Flange Drillings: DIN 2632/2633 Lining Material: PTFE (ASTM D4895), PFA (ASTM D 3307), FEP (ASTM D 2116), PVDF (ASTM D 3322), PP (ASTM D 4101) Lining Thickness: 3 mm to 5 mm Coefficient Of Friction : 0.05 to 0.10 Spark Test: 15 K.V.D.C Conductivity: 0.20 to 0.6 W/mK

|

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is the advantage of PTFE lining on Concentric Reducer?

- Why is the thickness of the lining important?

Lining thickness ensures effective protection against chemical corrosion and mechanical wear. A thicker lining increases durability, reduces the risk of damage from abrasive materials, and extends the life of the reducer, ensuring it can withstand harsh operating conditions without degradation.

- What is the difference between a concentric and eccentric Lined Reducer?

A PTFE Lined concentric reducer has a central, symmetrical design for a smooth transition between pipe sizes, ideal for standard flow applications. An PTFE Lined eccentric reducer, on the other hand, is designed to maintain the same flow level where precise alignment of the pipe is critical, such as in horizontal pipelines.

- Can these PTFE reducers withstand high pressure and temperature, and how much?

Yes, PTFE Reducers can withstand pressures up to 29 Kg/cm² and temperatures up to 265°C, making them suitable for high-pressure, high-temperature applications in industries like oil and gas, chemicals, and pharmaceuticals.

- How do I know which lining material is right for my application?

Freture offers a range of lining options including PTFE , PFA, PVDF, and FEP. For highly corrosive environments, PTFE or PFA linings are recommended, while PVDF or FEP may be more suited for moderate chemical resistance. Our technical exeprts can assist in selecting the best option for your needs based on your operating conditions.

- What maintenance considerations are associated with PTFE / PFA lined reducers?

While PTFE/PFA linings offer excellent durability, regular inspections are essential to detect potential issues like permeation or mechanical damage. Proper storage and handling, such as keeping end boards in place until installation, prevent damage to the linings.

Industries where PTFE Lined Concentric Reducer is Used

Pharmaceutical Industry

Chemical Industry

Food Processing Industry

Oil & Gas Industry

Pulp & Paper Industry

Applications

- Sterilization Systems: Maintains integrity and prevents chemical damage in high-temperature environments.

- Refinery Pipelines: Protects against chemical and thermal damage during the refining process.

- Chemical Transfer Lines: Protects from corrosion and contamination when handling reactive chemicals.

- Food Ingredient Transfer: Used to convey sensitive food materials without compromising their integrity or flavor.

- Sludge and Wastewater Transfer: Used to transfer wastewater and sludge without degrading the materials.