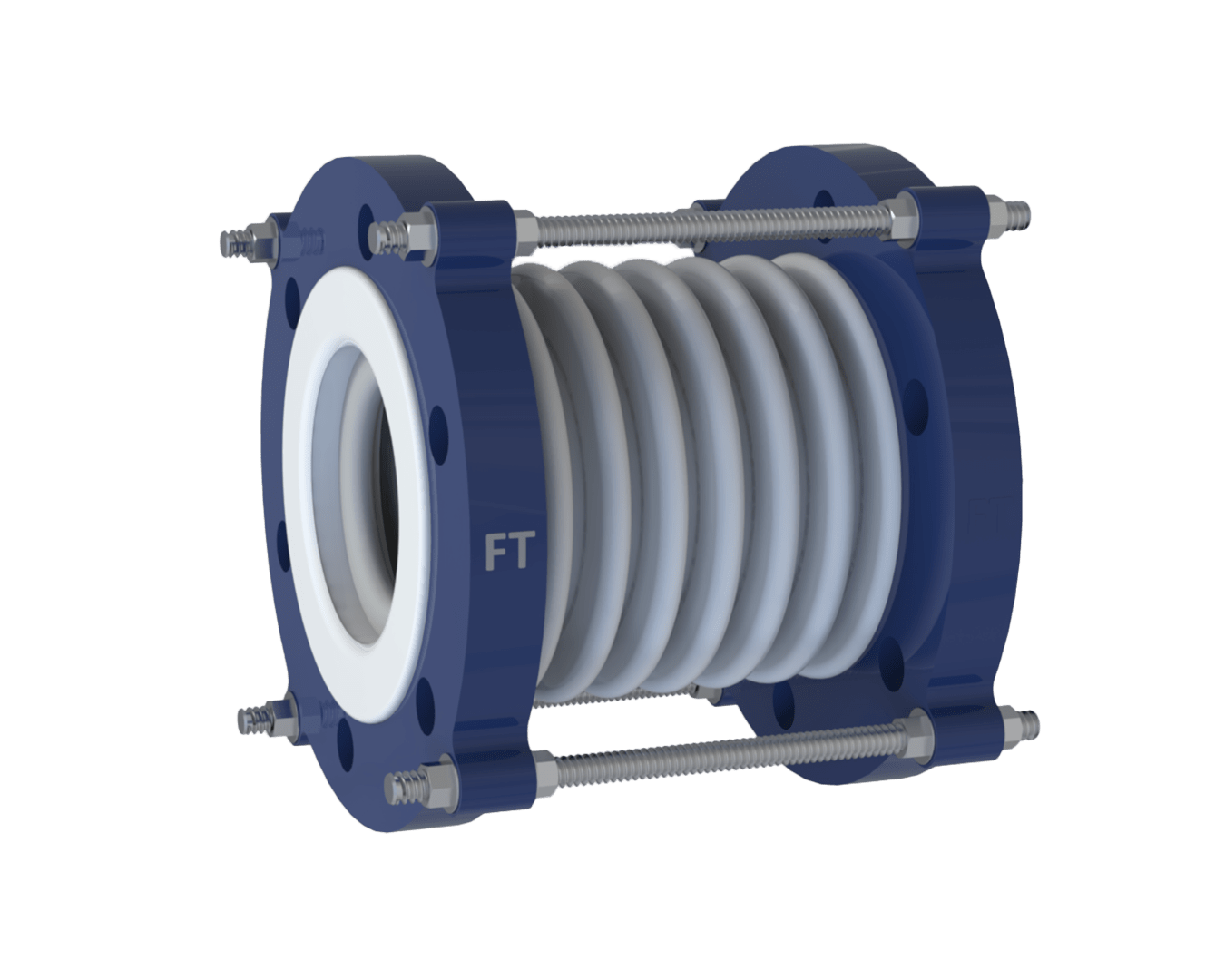

It is a flexible connector used in piping systems to absorb movements and vibrations. It features an expansion bellow structure lined with Polytetrafluoroethylene (PTFE), providing a leak-free seal and resistance to corrosive substances.

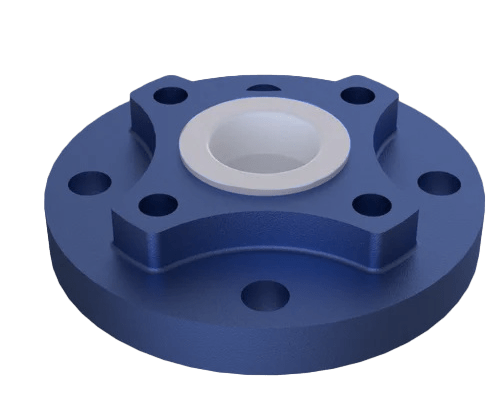

PTFE Lined Expansion Joint

We are leading Lined Expansion Joint Manufacturer in India. A PTFE lined expansion joint, also known as a PTFE expansion Bellow, is a specialized component in corrosion resistant piping systems designed to absorb movements, vibrations, and sudden shocks, accommodating thermal expansion and contraction while maintaining a leak-free seal. These joints are particularly designed for industries such as oil and gas, refineries, chemical processing, power generation, and petrochemicals, where high variations in temperature and movement are common during the transport of corrosive media.

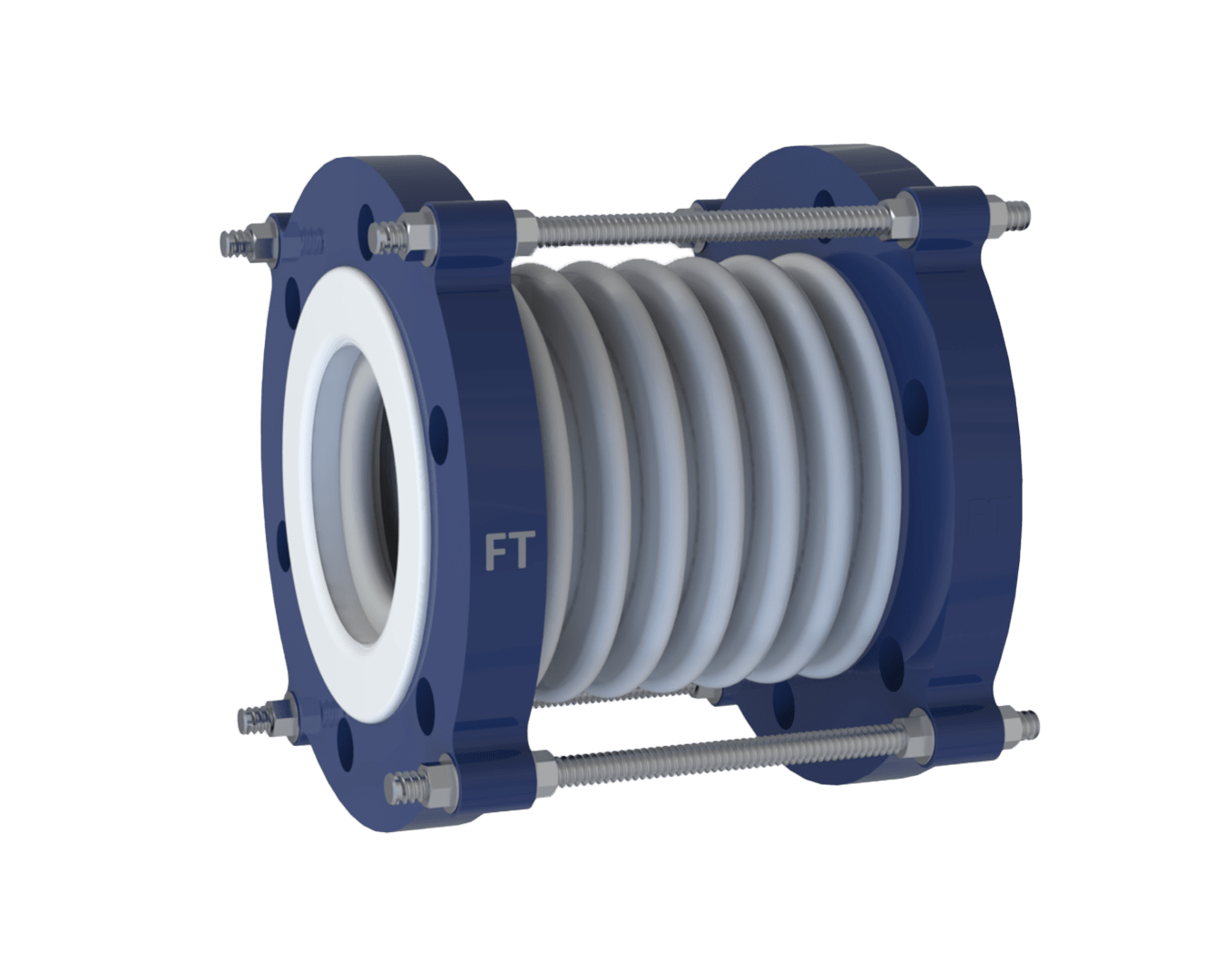

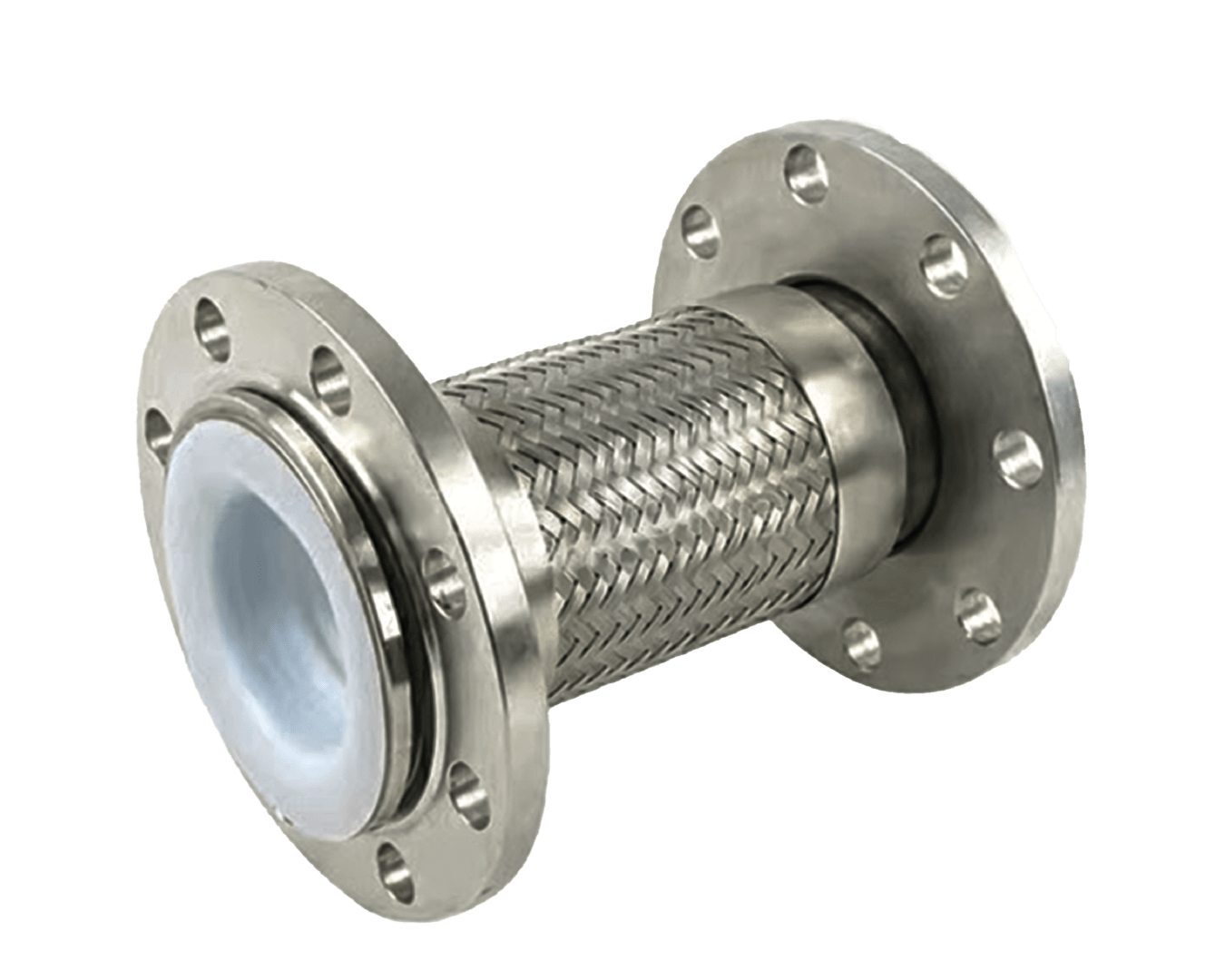

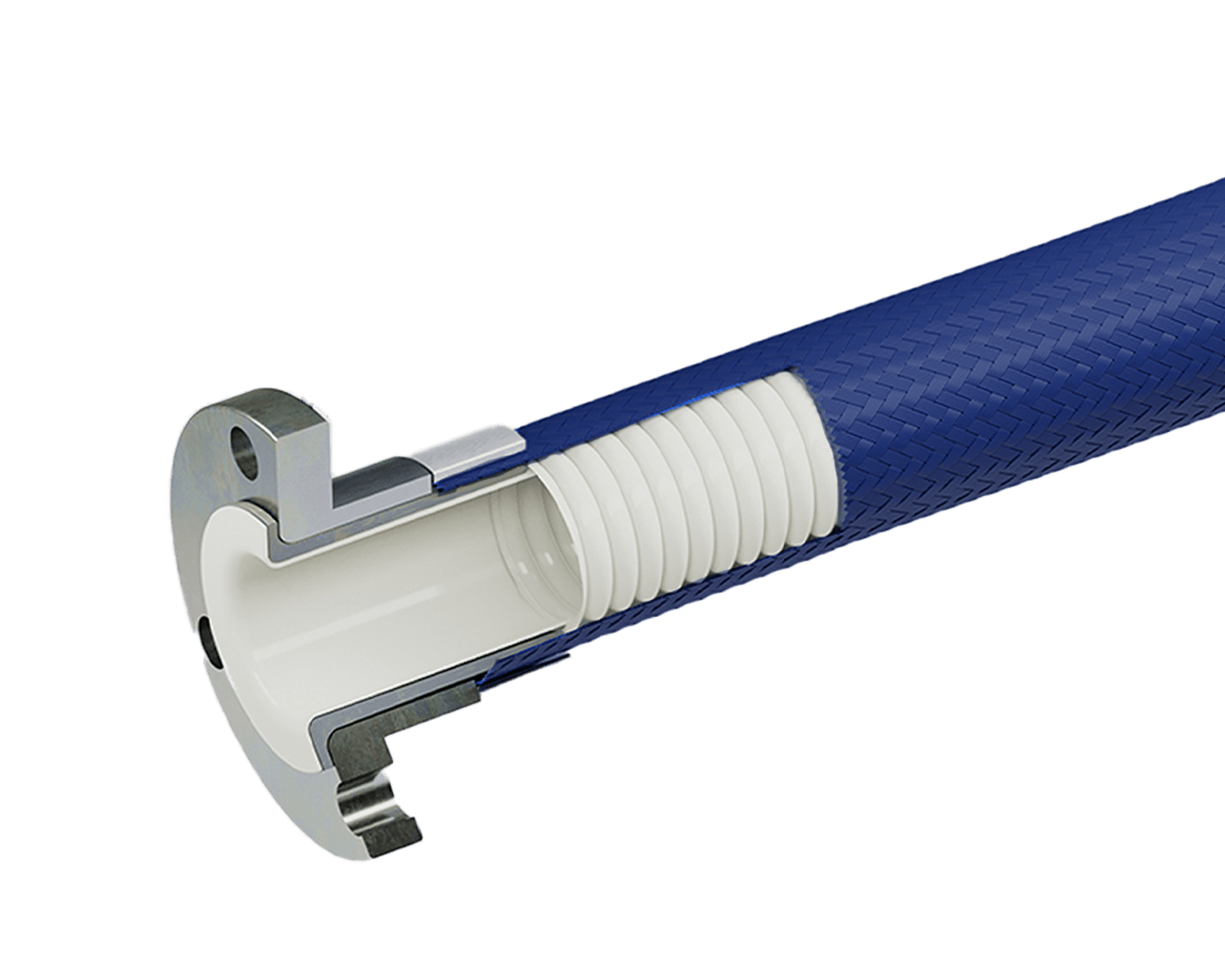

The PTFE expansion joint utilizes expansion bellows technology, typically made from materials like stainless steel outer shells with a 3 mm thick Teflon lining inside. They consist of a series of convolutions 2, 3, or 5 that allow for flexibility, enabling them to expand and contract within a certain range, ensuring the stability and integrity of the pipeline. The internal lining of PTFE enhances the bellows resistance to corrosive substances, thereby extending the lifespan of the expansion joint. Additionally, the lining provides a smooth surface with a friction coefficient between 0.05 and 0.10, minimizing turbulence and pressure drop within the system. This combination of flexibility and corrosion resistance allows these joints to effectively prevent stress-related damages and leaks.

Teflon / PTFE lined expansion joints into your Chemical, pharmaceuticals, Oil & Gas, and chemical processing plants. The corrosion-resistant lining enhances durability, reducing maintenance frequency and extending the service life of the system. The convoluted PTFE design of the lined bellows reduces system stress and strain. While these expansion joints are normally installed horizontally, vertical and perpendicular installations are also possible with ANSI B16.5 standard Connection. Their ability to absorb movements and vibrations contributes to operational safety by minimizing the risk of pipeline failures and leaks.

Specifications | Features |

|---|---|

Design Standard: ASTM G31 Pressure Range: PN 10 to PN 40 Size Range: 25 mm to 300 mm Body M.O.C.: Ductile Iron (GGG40.3 / ASTM A395), Cast Steel (ASTM A216 Gr. WCB), Stainless Steel (ASTM A351 CF8, CF8M) Operating Temperature: -29°C to 200°C Coefficient Of Friction : 0.05 to 0.10 Convolution Options: 3, 4, 5 Bellow Material: PTFE, Rubber, Flared Flanges: 316 Stainless Steel, ANSI 150#, B16.5 Reinforcing Rings: 316 SS, 304 SS Hydraulic Test: 29.8 kg/cm² Spark Test: 15 K.V.D.C Conductivity: 0.20 to 0.6 W/mK |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a PTFE lined expansion joint?

- What types of PTFE joints / Bellow are available?

They come in various configurations, including unreinforced PTFE and PTFE-lined metal designs. They are available with different convolution Bellows options typically 2, 3, or 5 convolutions to accommodate specific movement requirements.

- Why are expansion joints important against piping failure?

By absorbing movements, vibrations, and thermal contraction, expansion joints reduce stress which can break the weak & misaligned piping system. This absorption prevents potential leaks or major accidents, thereby having them is crucial.

- Why These joints should be used for thermal expansion problems?

Thermal expansion in pipelines occurs when temperature fluctuations cause pipes to expand or contract, potentially leading to issues such as bowing, buckling, or even fractures if not properly managed. Expansion joints are designed to absorb these dimensional changes, accommodating movements thereby maintaining the integrity and functionality of the piping system.

- What are the advantages of using PTFE lining this?

They offer high resistance to corrosion and chemicals, thermal stability, and flexibility. This Prevents Piping Failures, Breaks & extends the service life of the piping system.

- What industries benefit from these joints?

Industries such as Oil & Gas, Pharmaceutical, Chemical & petrochemical As well as Off shore refineries.

- How are PTFE expansion joint installed?

They can be installed horizontally or vertically according to the need. This Installation involves connecting joints ANSI B16.5 flanges or other suitable connectors. Proper alignment and support are crucial to ensure optimal performance and prevent premature failure.

- Is Teflon lined expansion joint Valve suitable for high-pressure applications?

Yes, Combined technology of Metal Bellow with non reactive PTFE Lining makes it compatible to deal with high pressure applications and corrosion media all at once.

Industries where PTFE Lined Expansion Joint is Used

Chemical Processing Industry

Pharmaceutical Industry

Food and Beverage Industry

Power Generation Industry

Oil and Gas Industry

Applications

- High-Pressure Systems: They accommodate pressure fluctuations in chemical reactors, maintaining safety and efficiency.

- Temperature Regulation: These joints manage thermal expansion in heat exchangers, preventing stress and potential failures.

- Vibration Absorption: They absorb vibrations from pumps and compressors, reducing wear on piping systems.

- Flexibility in Piping Layouts: PTFE lined expansion joint allow for complex piping configurations, facilitating design flexibility.

- Corrosion Resistance: They prevent degradation from aggressive cleaning agents used in pharmaceutical manufacturing.