Lined cross are used in piping systems to manage multi-directional flow of corrosive or reactive fluids, ensuring reliable performance and long-term protection against chemical attacks.

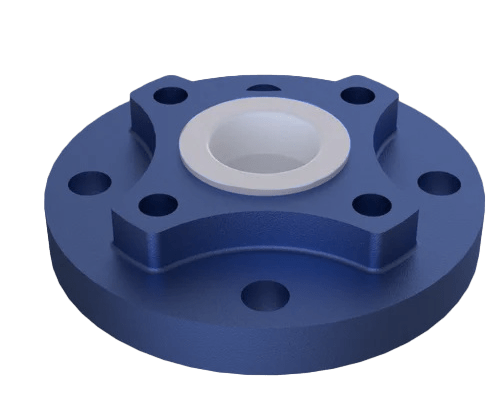

PTFE Lined Cross

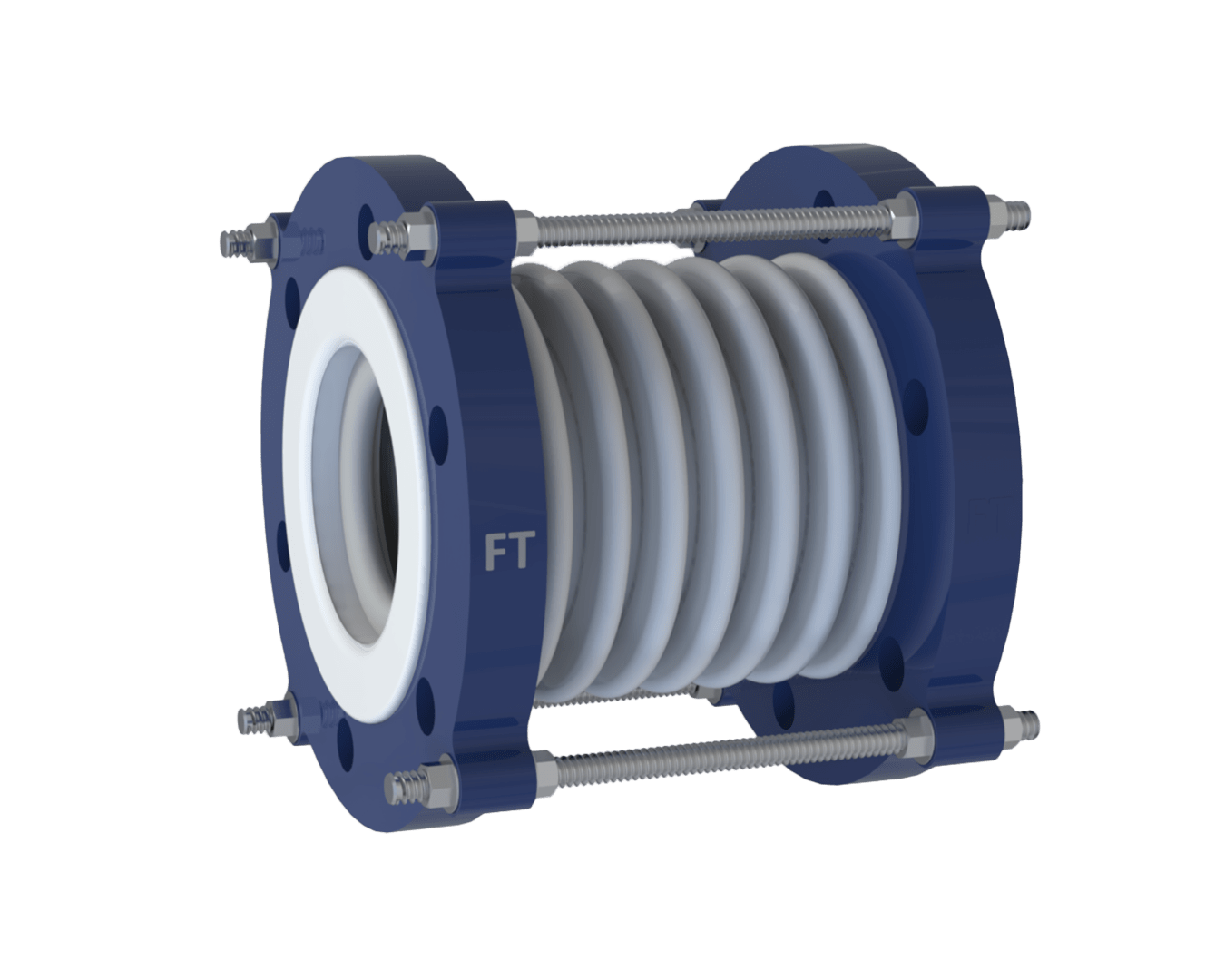

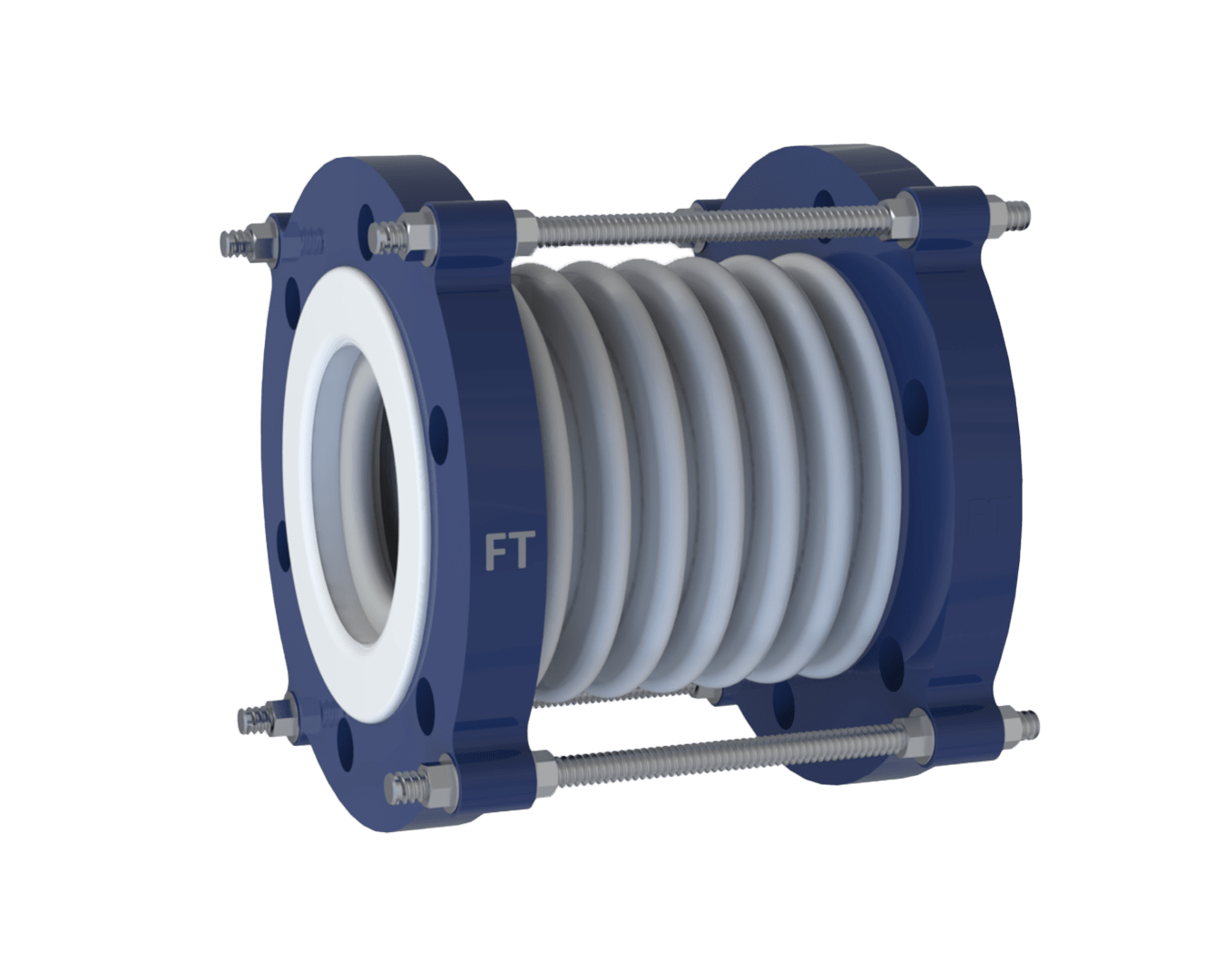

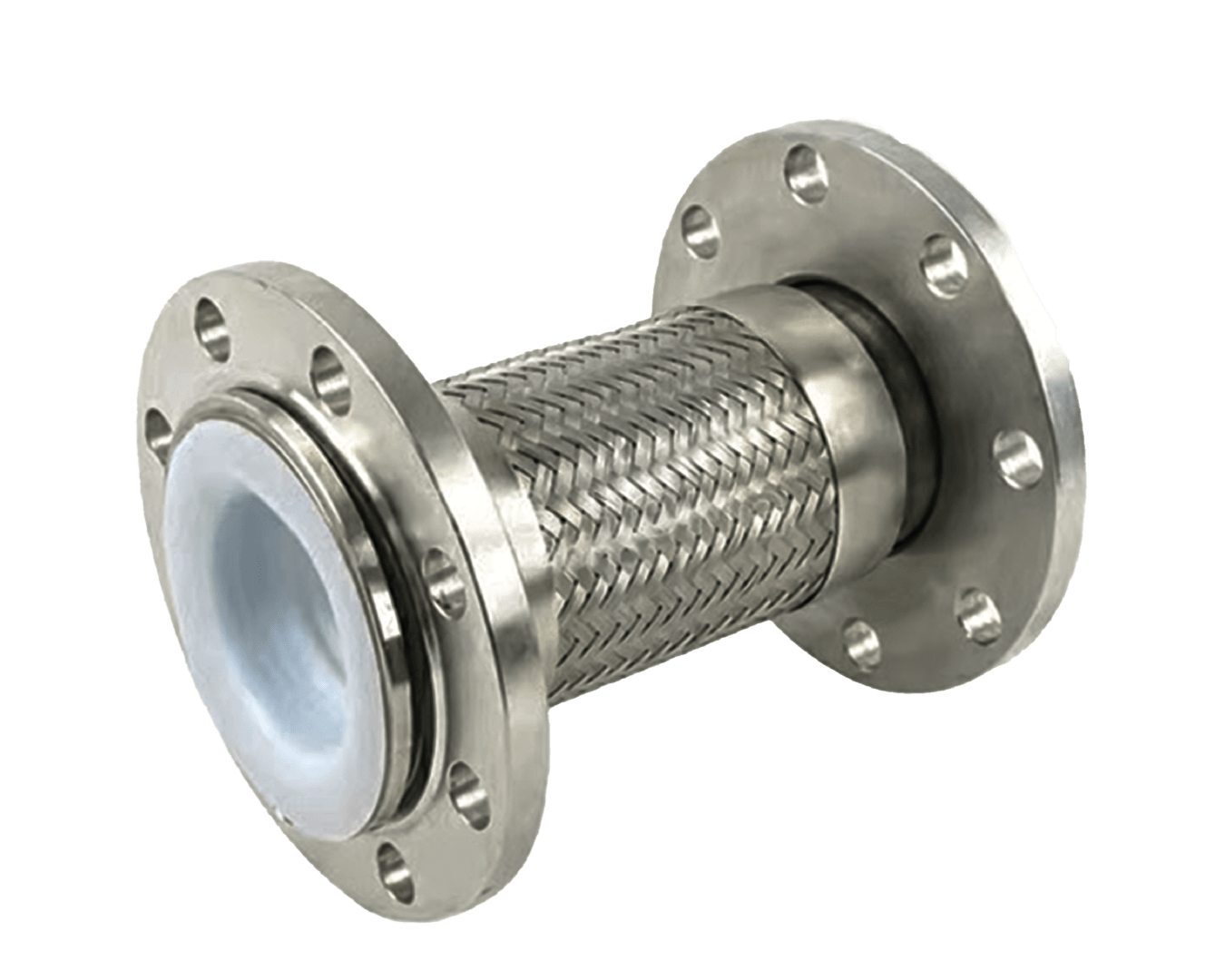

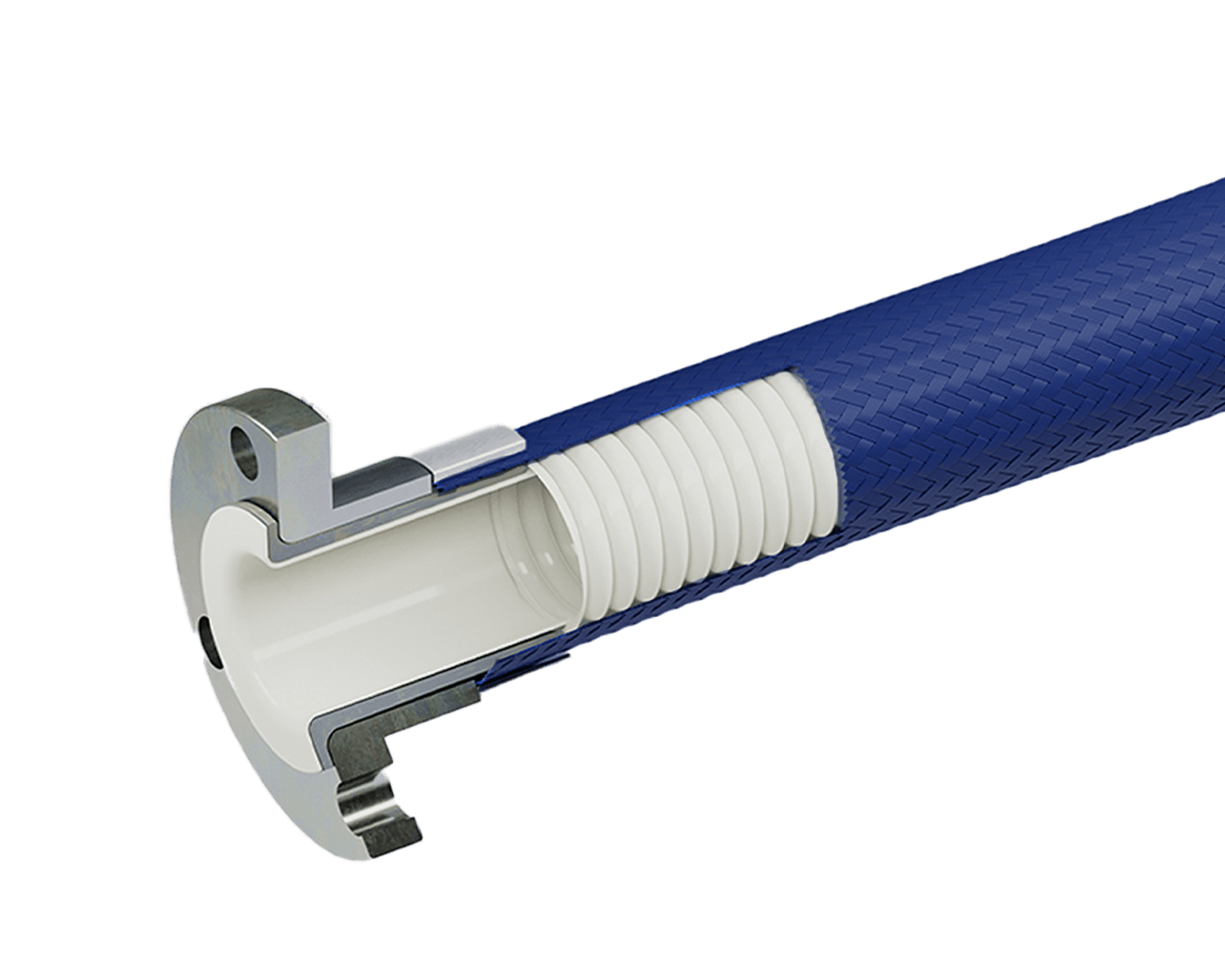

We are PTFE Lined Cross Pipe manufacturers in India. It is a specialized pipe fitting for complex piping networks where fluid is distributed or collected through four intersecting lines. PTFE Lined Cross is fully lined with high-performance fluoropolymers such as PTFE, PFA, FEP, or PVDF to provide an effective barrier against corrosive and abrasive media. Constructed with robust materials like ductile iron or carbon steel, the fitting ensures leak-proof connections and minimizes contamination, making it essential in industries like chemical processing, pharmaceuticals, and petrochemicals.

Technically, lined cross fittings are engineered to meet stringent industrial standards. They are available in various sizes, rated for pressures up to 150# (10-15 PN), and perform efficiently from sub-freezing temperatures up to 200°C. With a uniform lining thickness of 3 mm to 6 mm, these fittings maintain excellent adhesion and durability, conforming to face-to-face dimensions specified by ANSI B16.10 and DIN 3202. Rigorous hydraulic and spark testing further confirms their operational safety and structural integrity.

Incorporating PTFE Lined Cross fittings into your system offers significant benefits, including enhanced performance and sustainability. Their fully lined design eliminates direct metal-to-fluid contact, preventing corrosion and reducing maintenance needs, which translates into lower downtime and operating costs. Additionally, the cross configuration ensures balanced fluid distribution with minimized pressure drops, supporting efficient flow and a safer working environment while contributing to sustainable industrial practices.

Specifications | Features |

|---|---|

Size Range: 25 mm to 300 mm Types: Equal, Unequal, Reducing End Connection: ASME B16.5, ANSI B16.42 (Fixed or Loose) Material: Ductile Iron (GGG40.3 / ASTM A395), Cast Steel (ASTM A216), SS 304 (ASTM A351 Gr. CF8), SS 316 (ASTM A351 Gr. CF8M) Flanges: IS 2062 Plates, ASTM A105, CF8 (SS304), CF8M (SS316) Pressure:DIN PN10/16, 150#, 300# Lining Options: PTFE (ASTM D 1457), PVDF (ASTM D 3222), PFA (ASTM D 3418), FEP (ASTM D 2116), HDPE Lining Thickness: 3.5 mm to 6.0 mm Conductivity:0.20 to 0.6 W/mK Coefficient Of Friction : 0.05 to 0.10 Lining Spark Test: 20 KVDC Hydraulic Test: 29 Kg/Cm²

|

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is the primary purpose of a FEP / PFA/ PTFE Lined Cross?

- Which industries commonly use FEP/ PFA / PTFE Lined Cross?

These lined cross are widely used in industries like chemical processing, oil and gas, petrochemicals, pharmaceuticals, food and beverage, and water treatment.

- Why are PFA, FEP, and PTFE preferred as Lining materials?

These polymers provide excellent resistance to a wide range of corrosive chemicals, high temperatures, and pressures while ensuring non-reactive and contamination-free operation.

- What types of fluids can be handled with a Lined Cross?

PFA / FEP / PTFE lined cross can handle acids, alkalis, solvents, gases, and other aggressive or high-purity fluids without risk of degradation or leakage.

- Can these Lined Cross be used in food and pharmaceutical applications?

Yes, the non-reactive and contamination-free properties of the lining make them ideal for handling high-purity fluids in sensitive industries like food and pharmaceuticals.

- What makes Lined Cross a cost-effective solution for industries?

Their durability, corrosion resistance, minimal maintenance, and compatibility with harsh operating environments reduce operational costs and downtime, ensuring a high return on investment.

Industries where Lined Cross is Used

Chemical Processing Industry

Pharmaceutical Industry

Food and Beverage Industry

Power Generation Industry

Oil and Gas Industry

Applications

- Neutralization Pipelines: These fittings facilitate the safe blending of chemicals during neutralization processes, ensuring leak-free and contamination-free connections.

- Crude Oil Processing: In refineries, these fittings manage the flow of crude oil and intermediate products while resisting corrosive elements inherent in the process.

- Acid Distribution in Refining: They are used to distribute sulfuric acid and other corrosive catalysts reliably throughout the refining process.

- Pesticide and Fertilizer Manufacturing: They are essential in agrochemical plants where strong acids, bases, and solvents are handled, ensuring safe and efficient chemical transfer.

- Battery Manufacturing Plants: These fittings are used in battery production lines to handle electrolytes and aggressive chemical mixtures, offering resistance to corrosion and maintaining process integrity.