A PTFE Bellows is designed for long-lasting performance due to its resistance to corrosion, wear, and harsh conditions. With proper installation and maintenance, it can last for many years, reducing the need for frequent replacements.

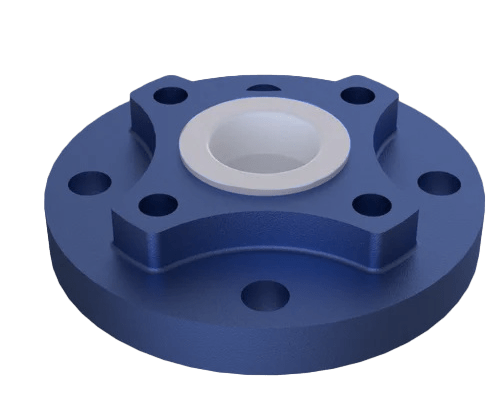

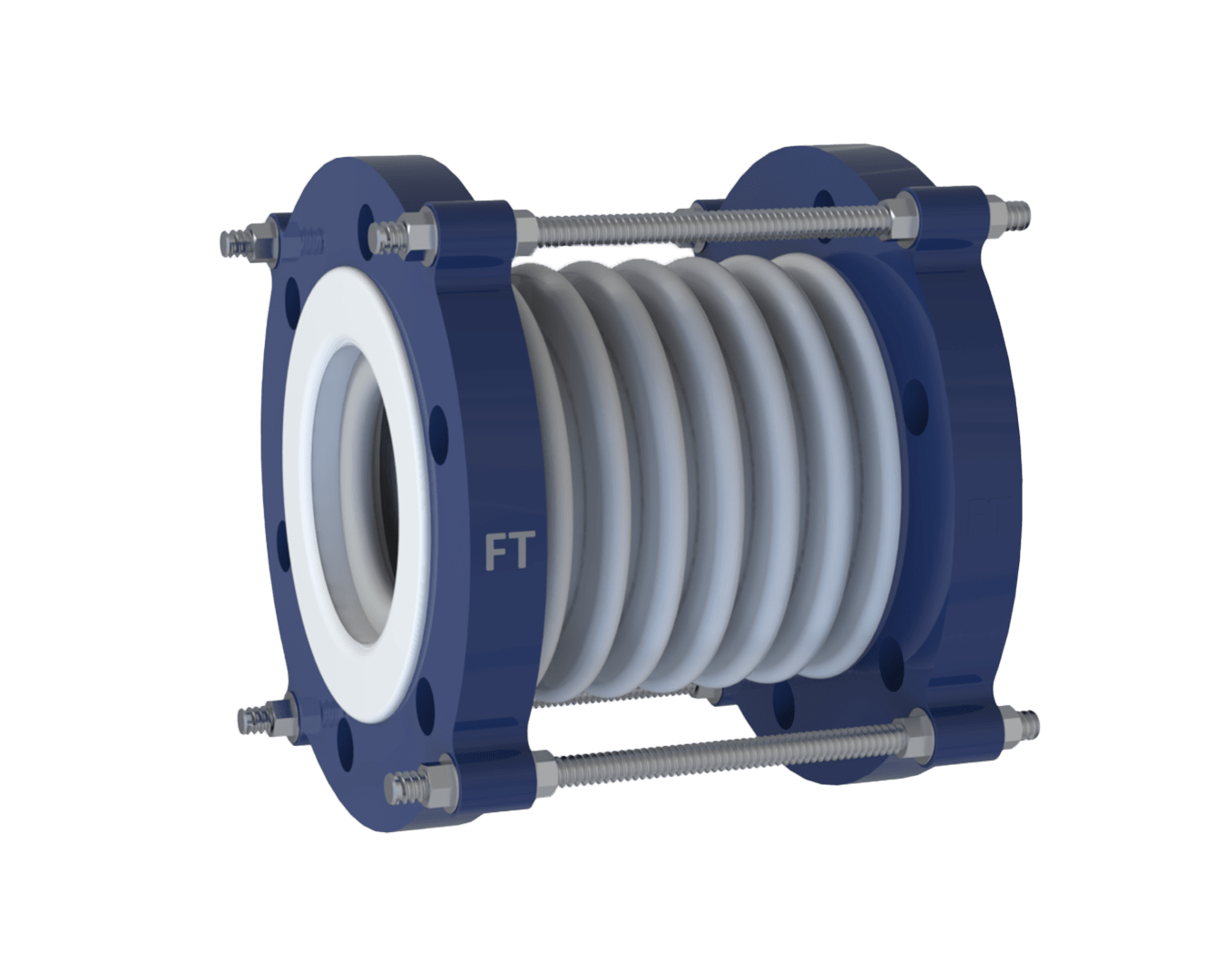

PTFE Bellows

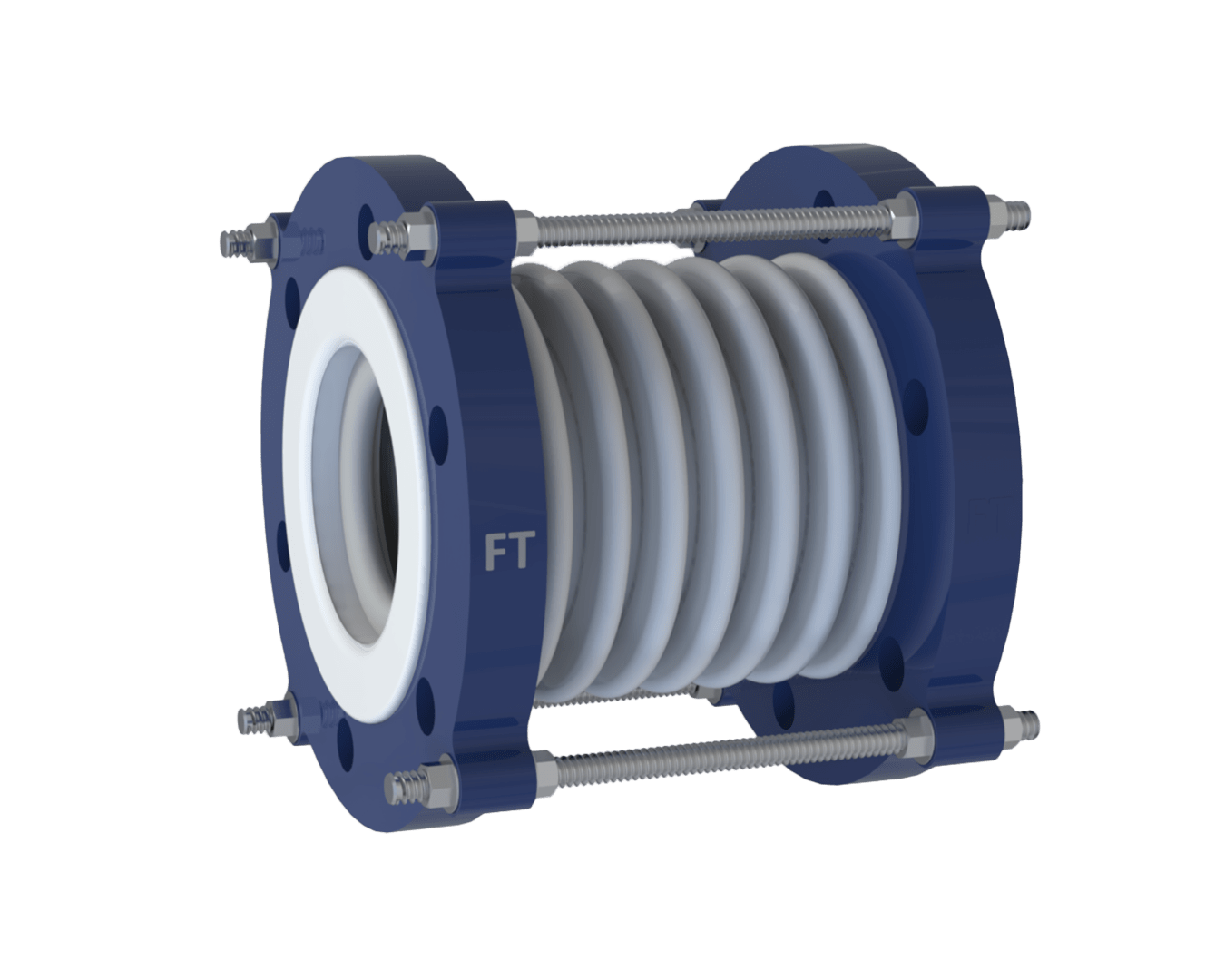

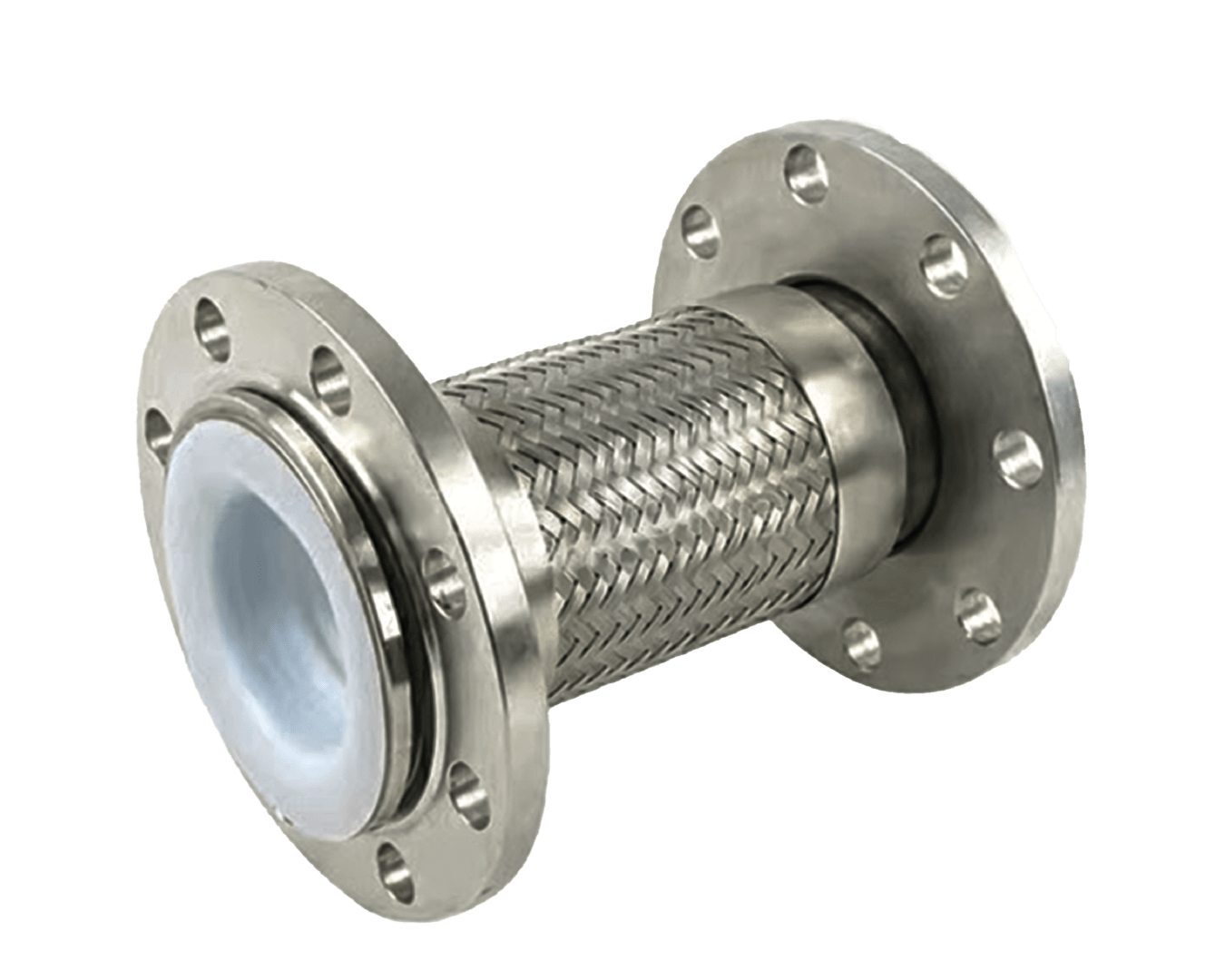

We are the leading PTFE Lined Bellows Manufacturer & Supplier in Mumbai, India. Teflon / PTFE Bellows is engineered to deliver unmatched flexibility, chemical resistance, and thermal stability in demanding industrial environments. Ideal for applications in chemical processing, pharmaceuticals, food production, and automotive systems, our PTFE expansion joint withstands extreme temperatures (-100°F to 500°F) and corrosive media. Its non-stick, low-friction surface ensures minimal maintenance and extended service life, making it a cost-effective solution for sealing, vibration absorption, and pressure compensation. Whether you need a standard or custom-designed bellow, our product meets rigorous industry standards for safety and performance.

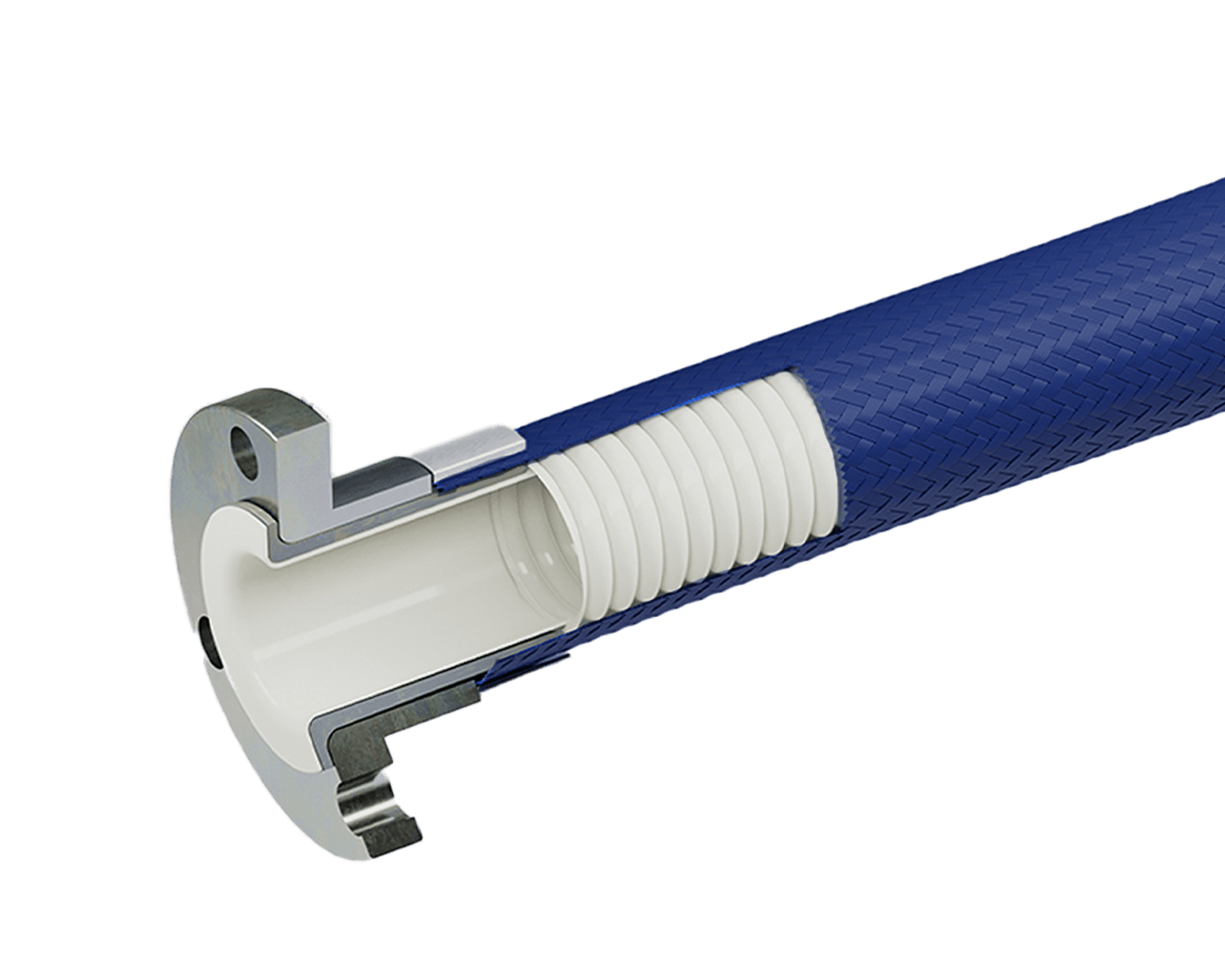

Designed to absorb lateral, angular, and axial movements, the Teflon / PTFE Bellows safeguards fragile equipment like glass-lined reactors and plastic vessels while minimizing vibration transfer in Teflon lined piping systems. Including a heavy-duty model for DN25–DN150, this versatile expansion joint handles shocks, linear expansion, and compression with precision. The high-grade PTFE expansion bellow construction ensures dimensional stability and low compression rates, while its maintenance-free design reduces lifecycle costs in corrosive or high-temperature environments.

Manufactured to exacting standards, the PTFE Expansion Bellows is available in all virgin and filled PTFE grades, with custom configurations tailored to unique industrial needs. Engineered for reliability in extreme conditions, this vibration-dampening Bellow protects sensitive equipment and ensures safe media transfer in critical pipelines. With exceptional chemical compatibility, extended service life, and adaptability to custom specifications, the PTFE Bellows is the go-to choice for industries demanding durable, corrosion-resistant pipeline solutions. Trusted globally, it optimizes operational safety and efficiency in chemical processing, power generation, and high-purity applications.

Specifications | Features |

|---|---|

Design Standard: ASTM G31 Pressure Range: PN 10 to PN 40 Size Range: 25 mm to 300 mm Operating Temperature: -29°C to 200°C Coefficient Of Friction : 0.05 to 0.10 Convolution Options: 3, 4, 5 Bellow Material: PTFE, Rubber, Flared Flanges: 316 Stainless Steel, ANSI 150#, B16.5 Reinforcing Rings: 316 SS, 304 SS Hydraulic Test: 29.8 kg/cm² Spark Test: 15 K.V.D.C Conductivity: 0.20 to 0.6 W/mK |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- How long does a Teflon / PTFE Bellows last?

- How does this provide Extra Protection?

By absorbing vibrations caused by pumps, compressors, and other rotating equipment in the pipeline system, it reduces mechanical stress on the pipes and protects sensitive components from damage.

- Why does a Bellows require PTFE lining?

PTFE lining provides excellent chemical resistance, protects against corrosion and abrasion, and withstands high temperatures. It ensures the bellow can handle aggressive fluids and gases, reduces wear, and minimizes pressure loss, making it ideal for industries like pharmaceuticals, chemicals, and food processing.

- What are the different convolutions available?

A Lined Expansion Bellows comes with 2, 4, or 5 convolutions to deal with different degrees of environmental challenges.

- Can this PTFE Lined Bellows handle Extreme Temperatures?

Yes, it is designed to withstand temperatures from -29°C to 200°C. The PTFE provides superior thermal resistance, making it suitable for high-temperature applications.

- How does it help to deal with thermal expansion?

A PTFE Lined Bellows can expand and contract along the pipeline as temperature changes. This flexibility helps compensate for thermal expansion and contraction, preventing damage to the piping system.

Industries where Lined Bellows is Used

Pharmaceutical Industry

Petrochemical Industry

Paper and Pulp Industry

Food And Beverage Industry

Waster Water Management

Application

- Vibration damping: Absorbs vibration caused by pumps and compressors in chemical processing systems.

- Corrosive media handling: Safely transports aggressive chemicals and solvents used in pharmaceutical processes.

- Expansion control: Compensates for thermal expansion in piping carrying hot or cold chemicals.

- Pressure and flow stabilization: Compensates for pressure variations in water treatment systems, ensuring smooth and efficient operations.

- Prevention of leakage in filtration units: Ensures tight seals in water filtration systems, preventing contaminants from escaping into treated water.