These are typically lined with high-performance materials like PTFE and PFA, which provide excellent corrosion resistance against aggressive chemicals.

PTFE Lined Tank and Vessels

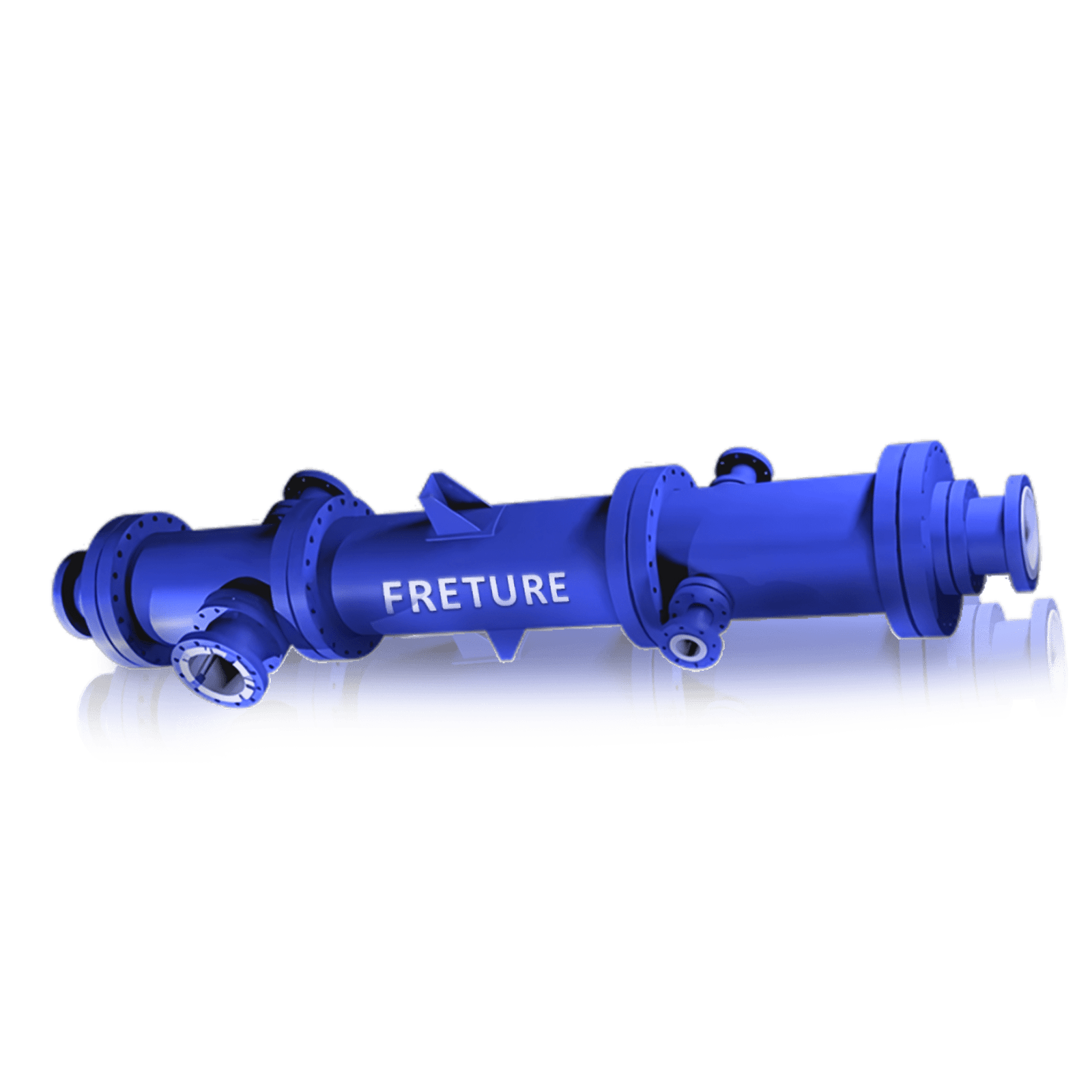

FRETURE TECHNO is Leading PTFE Lined tank and PTFE Lined vessel manufactured in Mumbai, India, ranging from 50L to 20,000L in capacity, are designed to safely store and mix harmful chemicals. Made with a strong carbon steel or stainless steel body, they are lined with Teflon materials like PTFE and PFA. These linings protect the Tank body from corrosion, even when handling aggressive chemicals such as acids, solvents, and alkalis. This lining ensures that the Vessel Tank can handle corrosive processes, such as HCl stripping, defluorination of H₃PO₄, and HF processing, without degrading.

The construction of PTFE lined tank and vessel typically involves a robust outer metal shell with 6mm thick Teflon lining from the inside. These Pressure Vessel or Mixing Tanks are used for various purposes, including storing chemicals, mixing liquids, and conducting reactions. They come with internal components like PTFE lined agitators and spray nozzles that help mix the chemicals evenly. Features like temperature sensors, sight glasses, and pressure relief valves allow for easy monitoring and control of the process, ensuring safety and efficiency. Whether for small or large-scale production, this provides reliable and safe solutions for mixing and storing harmful substances.

PTFE lined tank and PTFE lined vessels offer industries such as chemical processing, pharmaceuticals, food and beverages, power generation, and oil and gas industry significant benefits. Their leak-free design and low conductivity ensure safe handling of corrosive substances, while compliance with standards like EN 13445, EN 14483, and ASME Section VIII Division 1 guarantees reliability under pressures up to 25 psi and temperatures ranging from -29°C to +210°C. This durability leads to longer equipment life and lower operational costs, enhancing overall efficiency.

Specifications | Features |

|---|---|

Type: Vertical / Horizontal with Lining, Lined Mixing Vessel Design Standards: / ASTM A105 / IS 2062 / BS 4994 / API 650 / IS 4682-1 / EN 13445, EN 14483 Capacity Range: 50 L to 20,000 L Construction Material: Ductile Iron (GGG40.3 / ASTM A395), Cast Steel (ASTM A216 Gr. WCB), Stainless Steel (ASTM A312 TP304 / 316, SCH.-40) End Connections: ASME B16.5, ANSI B16.42, DIN EN 1092 Pressure : PN 10 to PN 16, 25 PSI Lining Material: PTFE Lining Options: PTFE ASTM D 4894 Lining Thickness: 3 mm to 10 mm Hydraulic Test: 29 Kg/cm² after lining Spark Test: 20 K.V.D.C after lining |

|

Related Products

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What materials are used for the linings of the tank and vessel?

- What is the pressure rating of lined tank and lined vessel?

Our PTFE lined tank and vessel are designed to handle pressures up to 25 Psi, making them suitable for high-pressure chemical processes.

- What temperature ranges can this handle?

It can safely operate in temperature ranges from -29°C to +210°C, ensuring they can handle both extreme cold and heat.

- Is this suitable for vacuum applications?

This is designed for vacuum applications. Implementing vent holes and selecting appropriate lining materials are crucial to prevent liner collapse under vacuum conditions.

- How can I ensure that the This PTFE Lined Vessel tank is suitable for my specific chemical process?

This is customizable to meet specific requirements. We provide detailed process data sheets and technical guidance to match the tank’s design with your application.

- Can this Tank be used for both storage and mixing Vessel purposes?

Yes, It comes PTFE lined agitators and spray nozzles that help mix the chemicals evenly.

- Can this tank be used in extreme environmental conditions like those in oil & gas industries?

Absolutely. The tank is built to withstand harsh environments, including high pressures, temperatures, and exposure to aggressive chemicals, making it suitable for oil, gas, and other heavy-duty industries.

- How does Ptfe lined Tank And Vessel contribute to sustainability?

The durability of steel and chemical resistance of Teflon Lining reduce the frequency of equipment replacements, leading to less material waste and lower environmental impact.

Industries where PTFE Lined Tank and Vessels is Used

Chemical Industry

Pharmaceutical Industry

Petrochemical Industry

Food & Beverage Industry

Oil and Gas Industry

Application

- Storage: Safely storing concentrated acids like sulfuric or hydrochloric acid.

- Solvent Mixing: Mixing volatile solvents without the risk of contamination or corrosion.

- Chemical Reactions: Containing and mixing chemicals for reactions, ensuring product purity and preventing unwanted reactions.

- Environmental and Waste Management Industry

- Bioremediation: Storing bioreactors or chemicals for bioremediation processes to break down waste.