It is a mechanical device designed to automatically release pressure from a system when it exceeds a predetermined limit to prevent equipment failure or explosion.

Safety Valve Series #077

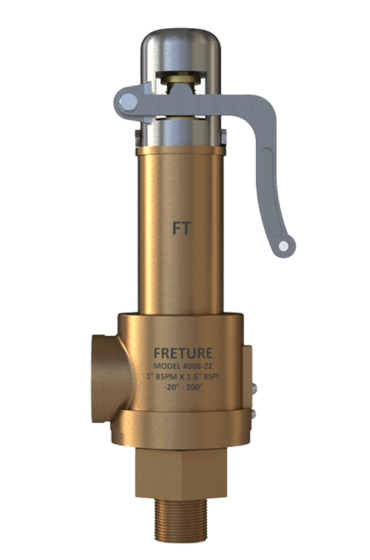

High Pressure Safety Valve Manurfacturer in Mumbai, India. Safety valve conforms to stringent standards, including ASME Section VIII Division 1, API 526 & 520, API 527, ASME 16.34, and IS 12992. Available in sizes ranging from 15NB - 200NB (Orifice "B" - "F"), it offers versatile end connections in both threaded and flanged options. set pressure range of 1 BAR to 255 Bar and a temperature range spanning from -196°C to 400°C, this valve features direct spring operation, full lift, full nozzle, adjustable blow-down ring, and a single trim. Designed for air, gas, steam, and liquid applications.

Description | Features |

|---|---|

TYPE: High Pressure, Direct Spring Operated, Full Nozzle & Single Trim Design End Connection: Thread End & Flange End Connection Size: ½” X 1” TO 1” X 1.5” Set Pressure Range: 0.5 to 255 Barg Temperature Range: -196°C to 400°C Body Materials: Stainless Steel, Carbon Steel, Brass, etc. Design Standard: API 520, API 526, API 527, API 521, EN ISO 4126 Part.1, ASME Section VIII Div. I, etc. Seat Options: Metal Seat or Soft Seat Operation: Spring-loaded, Pilot-operated, etc. Certification: CE Certified under Category IV Module H (2014/68/EU) |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a safety valve?

- Why are safety valves important?

why they are crucial for preventing overpressure conditions, which can lead to catastrophic equipment failure, fires, or explosions in industrial systems.

- How does a safety valve work?

A safety valve opens when the pressure in a system exceeds the set pressure, allowing excess pressure to be released until the system returns to a safe level.

- What are the common applications of safety valves?

Safety valves are used in various applications, including boilers, pressure vessels, pipelines, chemical processing plants, and other industrial systems requiring overpressure protection.

- What are the key components of a high-pressure safety valve?

The main components include the valve body, inlet and outlet connections, a spring, a disc or piston, and an actuator.

- What is "blowdown" in the context of safety valves?

Blowdown refers to the difference between the pressure at which a safety valve opens and the pressure at which it re-closes after the excess pressure has been released.

- What maintenance is required?

Regular inspection, testing, and cleaning are necessary to ensure the proper operation of safety valves. Periodic testing and recalibration should be conducted according to the manufacturer's guidelines or industry standards.

- Can they be repaired?

Yes, safety valves can often be repaired or recalibrated by qualified technicians. However, if the valve is extensively damaged or beyond repair, it may need to be replaced.

- How do you select the valve for an application?

Selection depends on factors like set pressure, temperature, flow rate, fluid type, and compliance with relevant standards and regulations.

- Why is Freture the best place to buy from?

Freture is the best place to buy safety valves because it offers a wide range of high-quality products, expert advice on selecting the right valve for your application, excellent customer service, and competitive pricing. Additionally, Freture ensures all products comply with industry standards, providing peace of mind and reliability.

Industries where High Pressure Safety Valve is used

Chemical Processing

Paper and pulp

Power Generation

Petrochemical Indsutry

Oil and Gas Industry

Applications of High Pressure safety valve

- Aerospace:Aerospace industries use high-pressure safety valves in propulsion systems and hydraulic systems to ensure safe pressure levels during flight operations and ground testing.

- Food and Beverage: They are employed in food processing plants and breweries to maintain safe pressures in cooking vessels, sterilizers, and other production equipment.

- Petrochemical: Petrochemical facilities use these valves to prevent overpressurization in processes involving the production of plastics, solvents, and other chemicals.

- Chemical Processing: They are used in chemical plants to safeguard reactors, vessels, and pipelines from excessive pressure that could lead to leaks or explosions.

- Power Generation: In power plants, high-pressure safety valves protect boilers, turbines, and steam systems from pressure buildup that could cause equipment damage or failure.