An angled type safety valve is a pressure relief valve designed with an angled body, typically at 90 degrees, used to protect equipment from overpressure by releasing excess pressure safely.

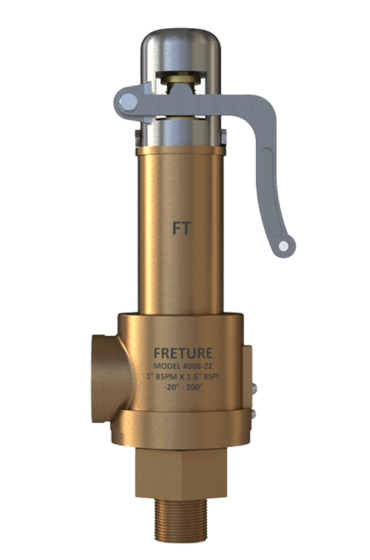

Safety Valve Series #008

FRETURE is leading Angled Pop Type Safety Valve manufacturer in Mumbai, India. Safety Valve complies with industry standards, including ASME Section VIII Division 1, API 526, API 527, EN ISO 4126, and IS 12992. Available in sizes ranging from 15NB - 200NB (orifice "D" to "M") and featuring thread end connections (BSP, BSPT, NPT), set pressure range of 1 BARG to 21 BARG and operates within a temperature range of -196°C to 530°C. Notable features include direct spring operation, full lift, full nozzle, adjustable blow-down ring, superior seat tightness, and a single trim, making good for air, gas, steam, and liquid applications.

Description | Features |

|---|---|

Valve Type: Angled Pop Type Safety Valve End Connection: Thread Connection (BSP, BSPT, NPT, etc.) Size: 15NB - 200NB Pressure Range: 0.5 to 21 Barg Temperature Range: -20°C to 250°C Body Materials: Stainless Steel, Carbon Steel, Brass, etc. Design Standards: API 520, API 526, API 527, EN ISO 4126 Part.1, ASME Section VIII Div. I, etc. Seat Material: Metal to Metal Operation: Direct Spring Operated & Pop Type action. Compliance: CE Certified under Category IV Module H (2014/68/EU) |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- 1. What is an angled pop type safety valve?

- How does an angle pop type safety valve work?

When system pressure exceeds a set threshold, the valve opens to release excess pressure. Once normal conditions are restored, the valve reseats and stops the flow.

- Where this valves typically used?

They are commonly used in boilers, pressure vessels, and various industrial systems where overpressure protection is crucial.

- Are there regulations governing its build?

Yes, there are industry standards and regulations , such as ASME (American Society of Mechanical Engineers) codes, that govern the design, testing, and maintenance, which Freture follows as safety valve manufacturers from Mumbai.

- What materials are used to build it?

They are often constructed from materials like stainless steel, brass, or bronze to withstand high pressure and corrosive environments.

- What Are the Benefits of Using One?

An angled pop-type safety valve offers quick pressure relief, prevents equipment damage, ensures safety, supports high-pressure systems, reduces downtime, and provides reliable operation with minimal maintenance.

- What is the difference between a pop-type and a conventional safety valve?

A pop-type valve opens fully and suddenly when set pressure is reached, providing immediate pressure relief, whereas a conventional valve may open gradually.

- How often they should be tested?

They should be tested periodically, typically every 6 to 12 months, depending on the application's safety requirements and regulatory guidelines.

- What maintenance procedures are recommended for it?

Regularly clean and inspect the valve for debris, check the spring tension, inspect the disc and seat for wear, and replace components as necessary.

- Why to choose freture?

Freture has years of experience in valve manufacturing. We understand the importance for safety in every industry and As a leading safety valve manufacturer, we provide the best solutions to your flow control and safety problems with cutting-edge technology and a team of experts. Freture is always committed to providing exceptional solution through our service.

Industries where Angle Type Pop Safety Valve is Used

Boiler and Reactors

Power Generation

Pharmaceutical Industry

Chemical Processing

Oil and Gas

Applications of Angle Pop Type Safety Valve

Power Generation: Critical in thermal and nuclear power plants to prevent steam boiler overpressure and ensure continuous electricity generation.

Reactor Systems: Essential for safety in chemical reactors, ensuring pressure remains within safe limits to prevent chemical reactions from becoming hazardous.

Boilers and Steam Systems: Used to protect boilers and steam pipelines from overpressure, ensuring safe operation and preventing catastrophic failures.

HVAC Systems: Employed in heating, ventilation, and air conditioning systems to protect against excessive pressure buildup, ensuring efficient and safe operation.

Food Processing: Used in equipment like autoclaves and sterilizers to maintain safe pressure levels during food processing and packaging.