A pressure reducing Valve (PRV) maintains precise downstream pressure, protecting systems from overpressure damage.

Pressure reducing Valve

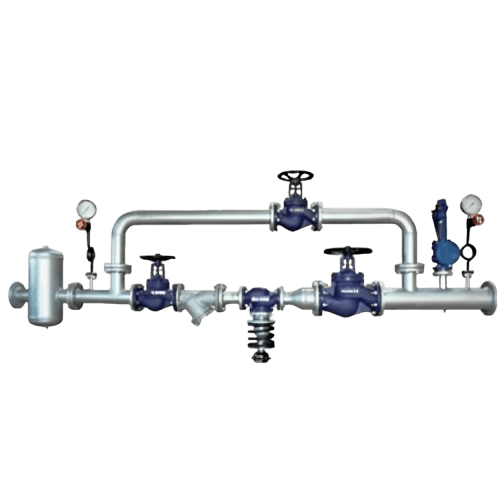

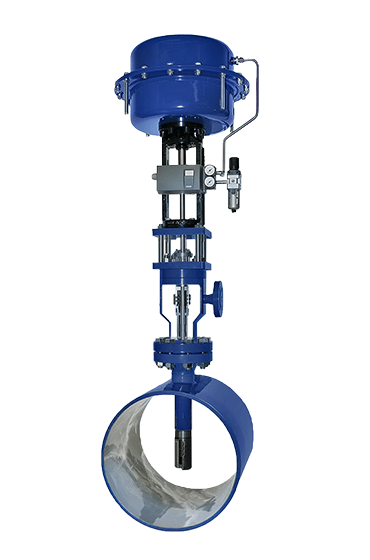

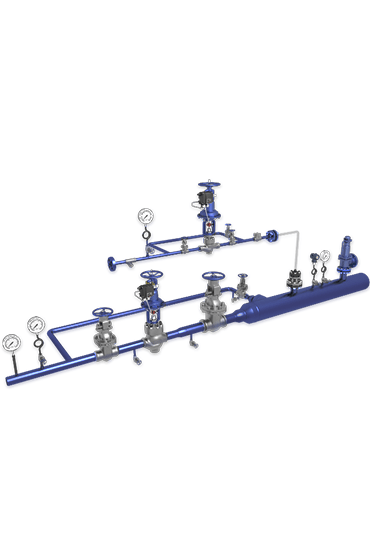

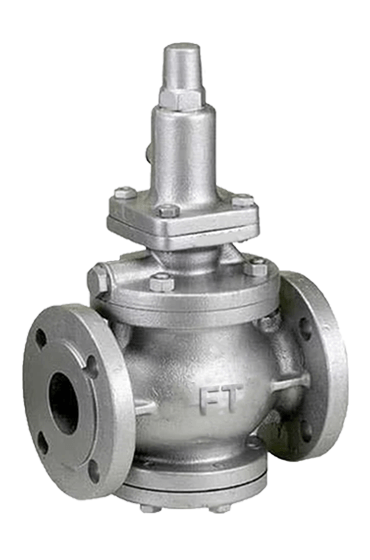

Pressure reducing Valve (PRV) is engineered to prevent risk of pipe bursts, valve seat erosion, and water hammer in unregulated high pressure applicationby maintaining precise downstream pressure. Cage-guided trims or V-port designs for linear control, paired with stainless steel bodies to resist corrosion and cavitation. PRV Valves become so important Because Unregulated high-pressure fluid or steam systems risk catastrophic failures, including pipe bursts, valve seat erosion, and water hammer, leading to costly downtime and safety hazards.

Advanced PRV Valve models incorporate pilot-operated diaphragms and multi-stage throttling to reduce noise and vibration, ensuring stable operation in critical systems like boiler feedwater lines, hydraulic networks, and gas distribution.Modern pressure reducing Valve feature Automation sensors and PID-driven actuators for real-time adjustments, syncing with SCADA systems to respond to load changes in <1 second.

Engineers prioritize balanced bellows designed PRV to negate upstream pressure effects and integrated strainers to prevent debris-induced seat damage. By maintaining optimal pressure profiles, pressure reducing Valve slash energy waste by up to 20%, prevent overstress in piping, and eliminate premature gasket failures—delivering an ROI-driven solution for industries demanding operational resilience.

Specifications | Features |

|---|---|

Type: Direct-acting, Pilot-operated, Dome-loaded Inlet Pressure Range: 50–600 # psi (3.4–41 bar) Outlet Pressure Range: Adjustable 15–300# psi (1–20.7 bar) Max Operating Pressure: 720 psi (50 bar) Temperature Range: 20°C to 180°C Flow Capacity (Cv): 2.5–25 Connection Type & Size: NPT, Flanged (R.F. , F.F) Body Material: Stainless Steel, Cast Iron, Carbon Steel, Alloy. Seat & Seal Material: EPDM, Viton, PTFE Accuracy: ±5% of set pressure Leakage Class: ANSI/FCI 70-2 Class IV or VI Adjustment Mechanism: Pilot, Knob, Screw. Standards Compliance: ASME, ISO, EN, PED Certifications: ANSI 61, PED

|

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is the primary function of a pressure reducing valve?

- What pressure ranges can industrial PRV handle?

High-performance reducer Valves operate from 0.5 bar to 420 bar (7–6,000 psi).

- How do PRVs prevent cavitation and noise?

Advanced designs use multi-stage trims, anti-cavitation cages, or V-port throttling to dissipate energy gradually, reducing turbulence and vapor bubble formation.

- What materials are used for corrosive applications?

Bodies use CF8M stainless steel; trim components use Stellite 6 or Inconel 625 for erosion resistance.

- Can PRVs handle steam, gases, and liquids?

Yes, but trim designs vary: globe-style valves for steam/gases, angle-body valves for liquids with particulates (e.g., wastewater).

- Pilot-operated PRV vs. direct-acting reducing Valve?

Pilot-operated pressure reducing Valve offer ±1% accuracy for large systems; direct-acting suits stable systems (±10%).

- Do PRVs require external power sources?

Most are self-contained, using system pressure for operation. Pilot valves or electro-pneumatic controllers may need auxiliary power for precision.

Industries where Pressure Reducing Valve is Used

Chemical Processing

Pharmaceutical Industry

Power Generation

HVAC System

Oil and Gas Industry

Application

- Steam Pressure Reduction: Optimizes steam pressure for heat exchangers, improving energy efficiency.

- Boiler Feedwater Pressure Control: Ensures stable pressure for efficient boiler operation,

- preventing overheating and energy waste.

- Wellhead Pressure Management: Maintains optimal pressure during extraction, safeguarding pipelines and equipment

- Pump Protection: Reduces pressure surges, extending pump lifespan and reducing maintenance costs.

- Hazardous Fluid Handling: Controls pressure in corrosive or toxic fluid systems, ensuring operator safety and system integrity.