It is a quarter-turn rotary valve that does not require lubrication for operation. It uses a self-lubricating polymer sleeve, elastomeric seals, or a lined interior to provide smooth movement and a tight shutoff.

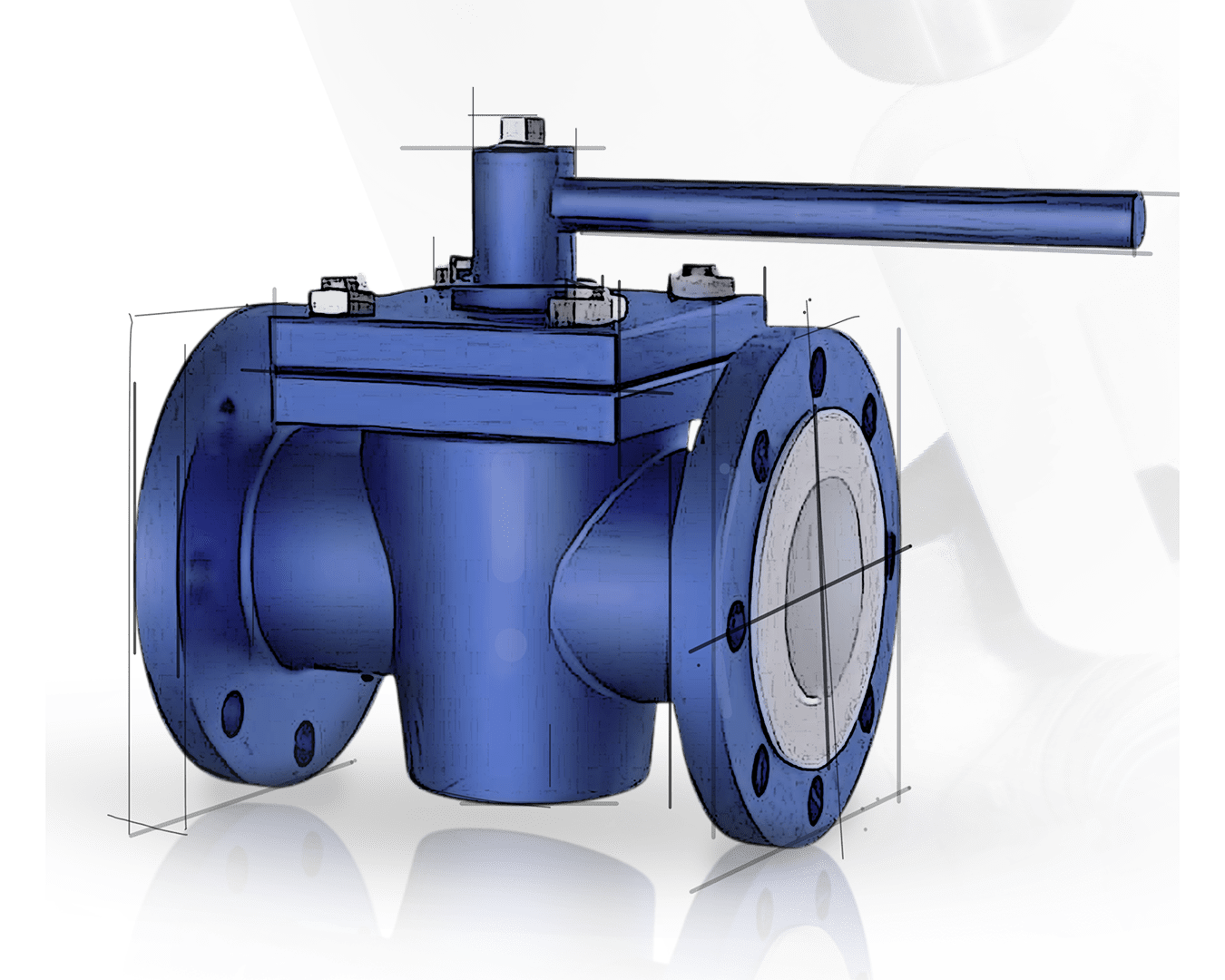

A Non-Lubricated Plug Valve is a quarter-turn rotary valve designed for on-off and throttling applications without the need for lubrication. Unlike lubricated plug valves, these valves use a self-lubricating polymer sleeve, elastomeric seals, or metal-to-metal contact for smooth operation. They are preferred for applications requiring minimal maintenance, contamination-free performance, and extended service life.

✔ Maintenance-Free Design – No need for periodic lubrication, reducing operational costs.

✔ Zero Contamination Risk – Ideal for applications in food, pharmaceuticals, and chemicals.

✔ Superior Corrosion Resistance – Lined and sleeved variants withstand aggressive media.

✔ Lower Torque Requirements – Operates smoothly without excessive force.

✔ Reliable Bubble-Tight Shutoff – Provides excellent sealing performance.

✖ Limited Pressure and Temperature Ratings – Typically lower than lubricated plug valves.

✖ Not Ideal for High-Torque Applications – Sleeved designs may not handle extreme pressures.

✖ Sleeve or Liner Wear Over Time – Requires periodic replacement in high-cycle applications.

Specifications | Features |

|---|---|

Type : Non-Lubricated Plug Valve End Connection: Flanged, Threaded (BSP/NPT), Socket Weld, Butt Weld Size: ½” to 24” Pressure Rating: ANSI Class 150, 300, 600 Temperature Range: -50°C to 250°C MOC (Material of Construction): Carbon Steel (WCB, LCB), Stainless Steel (CF8, CF8M), Duplex, Super Duplex, PTFE/PFA Lined Design Standard: API 6D, API 599, ASME B16.34, BS 5353 Cycle Life: High cycle life with minimal wear Face to Face: As per ASME B16.10 and API 6D Operation: Manual (Lever/Gear), Pneumatic Actuator, Electric Actuator Fire Safe Design: API 607 / API 6FA Compliant (for metal-seated variants) Testing: Hydrostatic and Pneumatic Testing as per API 598 / API 6D Documents: Material Test Certificate (MTC), Pressure Test Report, Fire Safe Test Report, PMI Report, IBR & Third-Party Inspection Certificate

|

|

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

It is a quarter-turn rotary valve that does not require lubrication for operation. It uses a self-lubricating polymer sleeve, elastomeric seals, or a lined interior to provide smooth movement and a tight shutoff.

The valve has a tapered or cylindrical plug with a flow passage. When rotated 90 degrees, the passage aligns with the pipeline for flow or blocks it to stop flow. The self-lubricating design ensures low friction and smooth operation.

✔ Maintenance-Free – No need for periodic lubrication.

✔ Leak-Tight Sealing – Provides excellent shutoff performance.

✔ Corrosion Resistance – Lined and sleeved options handle aggressive fluids.

✔ Compact and Lightweight – Easy to install and operate.

✔ Ideal for Clean Environments – Used in food, pharmaceuticals, and chemicals.

Common materials include carbon steel (WCB, LCB), stainless steel (CF8, CF8M), duplex steel, and PTFE/PFA/FEP lining for enhanced chemical resistance.

Yes, these valves can be fitted with pneumatic, electric, or hydraulic actuators for remote and automated operation.

Testing is performed as per API 598 and API 6D, including hydrostatic, pneumatic, and fire-safe testing, to ensure performance and reliability.

They are generally recommended for low to medium-pressure applications. For high-pressure systems, lubricated plug valves may be preferred.