A Teflon Lined Plug Valve is designed with a PTFE, PFA, or FEP lining to protect against corrosion, abrasion, and chemical degradation. It is commonly used in industries handling aggressive, corrosive, or abrasive fluids to ensure longevity, leak-proof operation, and smooth flow control.

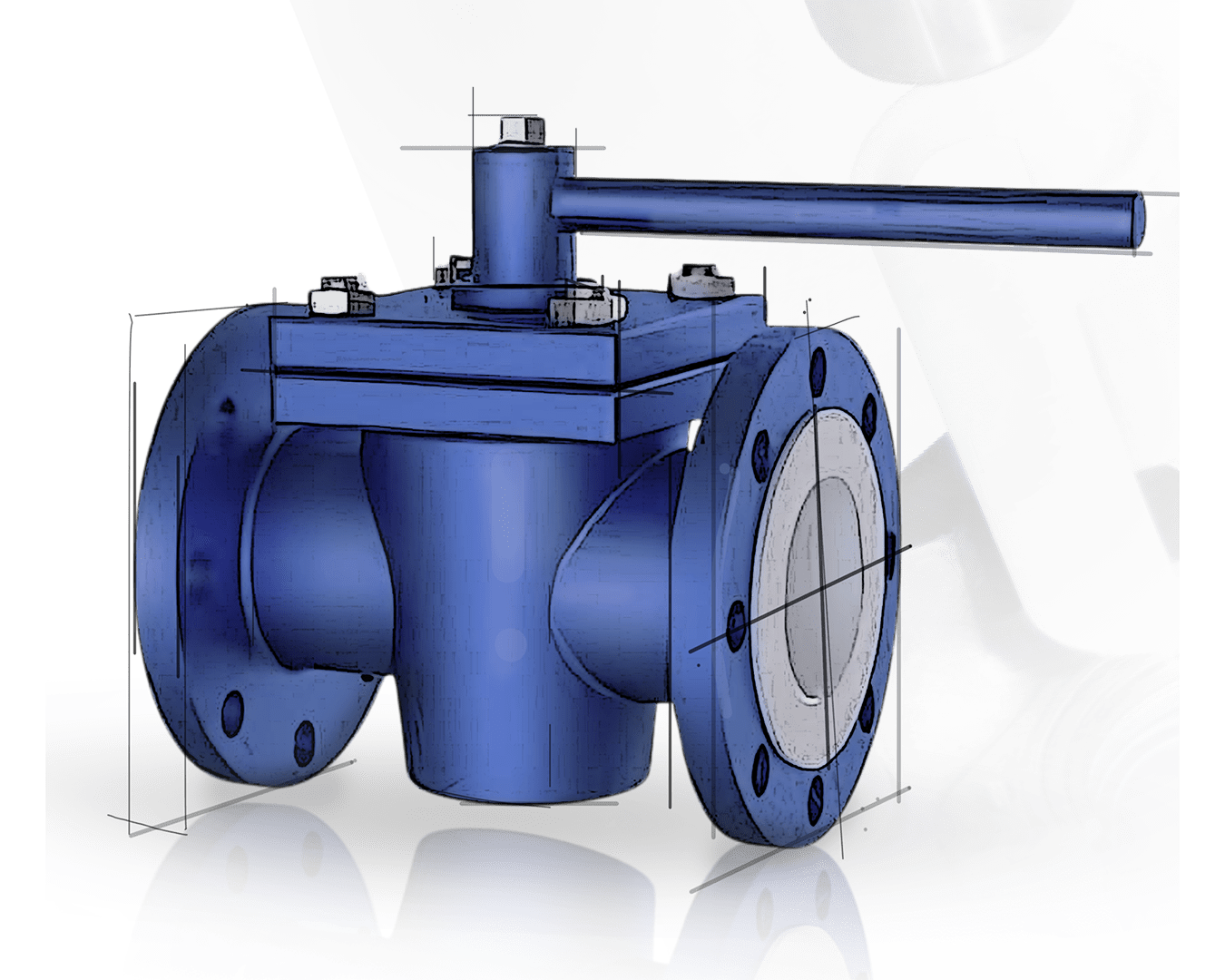

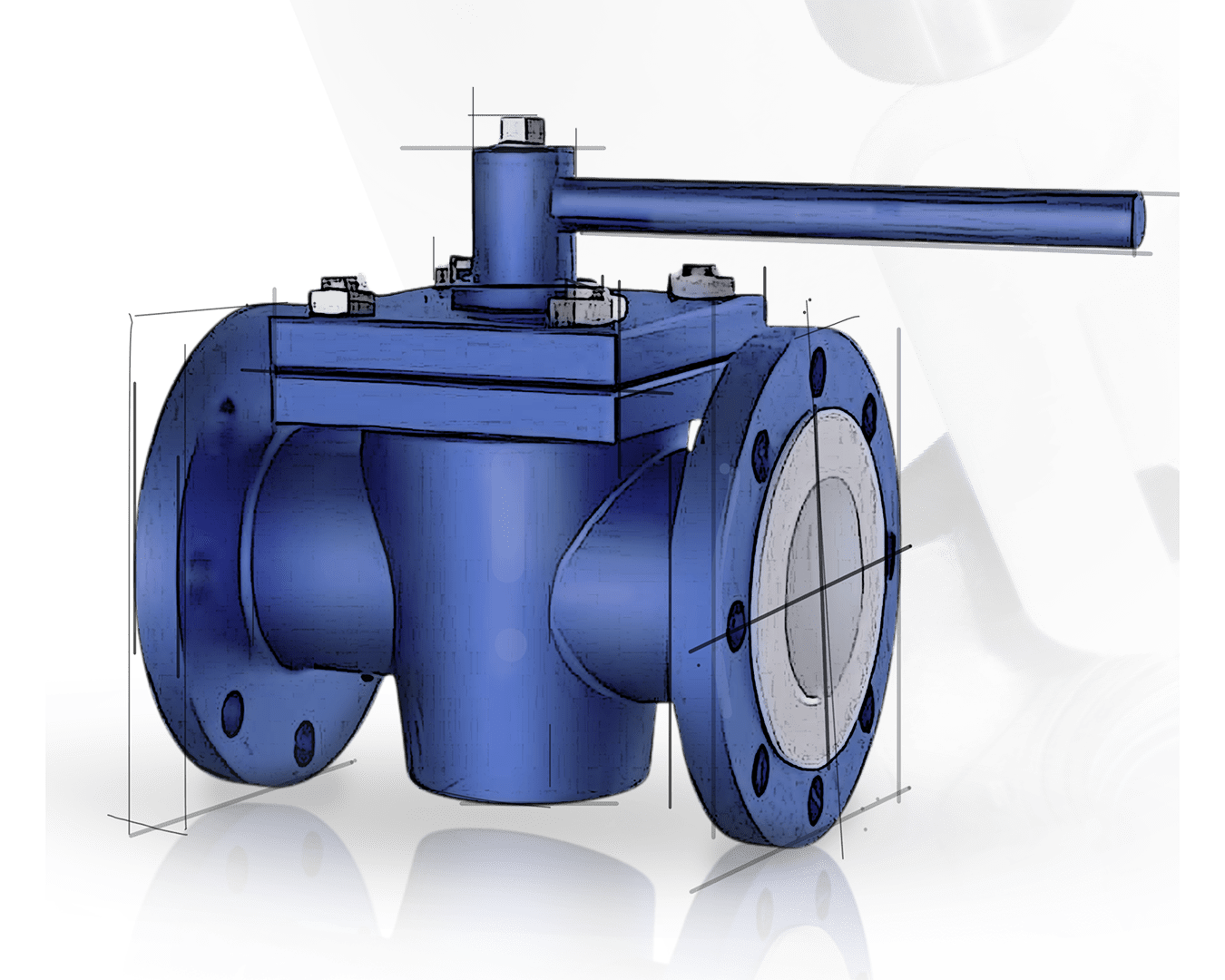

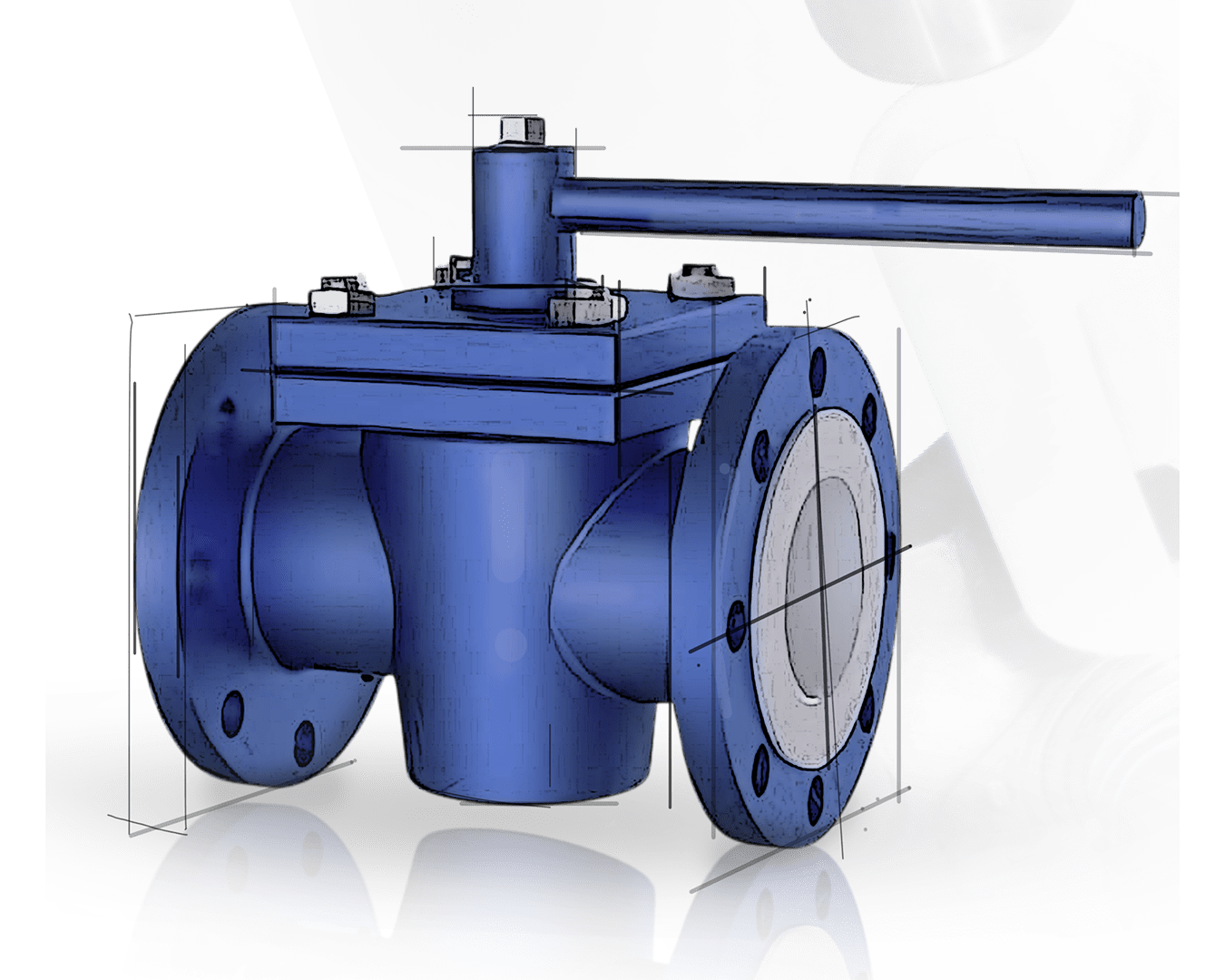

PTFE / PFA Lined Plug Valve

A PTFE / PFA lined Plug valve is a specialized flow control device designed to regulate the movement of fluids through pipelines, particularly in industries handling corrosive or high-purity substances. Typically constructed from materials like stainless steel or cast iron (BS 5158:1989) internally lined with Low Porosity PTFE / PFA to meet design Standards. This lining provides exceptional chemical resistance and a low friction coefficient, ensuring smooth operation and enhanced durability. The valve's core component, the plug, Comes with PTFE / Teflon and features a cylindrical or tapered shape with a transverse opening. Rotating the plug 90 degrees aligns or obstructs the flow passage, allowing for quick and efficient flow control.

The lining is applied using transfer molding, which guarantees a smooth, seamless finish and is securely locked into place using machined dovetail grooves. This innovative PTFE / PFA Lined Plug Valve design prevents liner collapse under vacuum conditions and blowouts under high-pressure and high-temperature environments, ensuring superior performance and durability. Additionally, Teflon’s low coefficient of friction reduces wear and tear, minimizing maintenance requirements and ensuring smooth operation. The design allows for accurate fluid flow control, essential in many industrial processes. Furthermore, they are easy to clean and maintain, making them ideal for industries with strict hygiene requirements.

One of the key features of PTFE Lined Plug Valve is its cavity-free design. Both the open and closed positions are designed to eliminate areas where particles can accumulate, preventing blockages and contamination. This makes the valve ideal for applications where corrosive slurries and aggressive media are handled. By ensuring reliable flow control in demanding applications, lined plug valves support sustainable industrial practices and help maintain the integrity of critical processes. Lined / Sleeved plug valves are available in various configurations & sizes, including Full Port Plug Valve, two-way (straight-through) and three-way designs, to accommodate different flow control of chemical processing, pharmaceuticals, and water treatment industry.

Specifications | Features |

|---|---|

Type: PTFE / PFA Lined Plug Valve Design Standard: API 599, BS 5158, API 593, ASME B16.34 Body / Plug M.O.C.: Steel Fabrication (ASTM A234 Gr. WPB), Ductile Iron (GGG40.3 / ASTM A395), Cast Steel (ASTM A216 Gr. WCB), Stainless Steel (ASTM A312 TP304 / 316, SCH.-40) Size Range: 15 mm to 200 mm Nominal Pressure: P10/PN16, #150 Working Temperature: -29°C to 210°C Face to Face: ANSI B16.10 Lining Thickness: 3 to 5 mm Lining Material: PFA (ASTM D 3307), FEP (ASTM D 2116), PVDF (ASTM D 3322), PP (ASTM D 4101) Seat Material: EPDM, PTFE, NBR, Viton Coefficient Of Friction : 0.05 to 0.10 Leakage Class: ANSI/FCI 70-2 Class IV Actuator Type: Pneumatic, Scotch Yoke, Rack & Pinion Accessories: Positioners, Limit Switches, Handwheels Certifications: CE, ATEX, SIL, ISO 9001, PED Spark Test: 15 K.V.D.C Conductivity: 0.20 to 0.6 W/mK Operation Options: Manual, Pneumatic, Electric |

|

Related Products

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Lined Plug Valve, and why is it used in my industry?

- What are the benefits of using PTFE Plug Valves in chemical processing?

These valves provide excellent chemical resistance, preventing valve failure due to the aggressive nature of acids, solvents, and other chemicals, ensuring safe and reliable operation in harsh environments.

- Can PTFE Plug Valves be used in food or pharmaceutical applications?

Yes, these valves are suitable for industries like food, beverage, and pharmaceuticals, where they provide safe, contamination-free flow control in high-purity environments.

- What is cavity-free design and how does it benefit me?

The cavity-free design ensures there is no place for particles to accumulate, which prevents clogging or contamination. This feature is especially useful for handling slurries and viscous fluids.

- How long does the PTFE lining last under harsh operating conditions?

The lining thickness of 3 to 5 mm provides enhanced durability, extending the valve's life by protecting it from chemical corrosion, abrasion, and erosion in demanding environments.

- What makes PTFE Lined Plug Valves more cost-effective than traditional valves?

These valves offer excellent performance with a lower total cost of ownership due to their durability, reduced maintenance needs, and longer service life, making them a cost-effective solution for industries handling corrosive and abrasive fluids.

Industries where Lined Plug Valve is Used

Food And Beverages

Oil Refineries

Wastewater Treatment

Pharmaceutical Industry

Chemical Manufacturing

Application

- Corrosive Chemical Handling: Managing the flow of aggressive chemicals, ensuring safe and efficient processing.

- High-Purity Fluid Control: Maintaining the purity of sensitive fluids by preventing contamination during transfer.

- Treatment Chemical Regulation: Controlling the dosage and flow of chemicals used in various treatment processes.

- Aggressive Agent Management: Handling the flow of strong agents used in various industrial processes.

- Abrasive Slurry Control: Regulating the movement of abrasive mixtures in processing operations.

- Ultra-Pure Chemical Handling: Controlling the flow of ultra-pure and corrosive chemicals in specialized manufacturing processes.