A manifold is a component used in fluid control systems to distribute fluid from a single source to multiple destinations or combine fluid from multiple sources into a single output. It serves as a central hub for fluid distribution, ensuring efficient and organized flow management.

Manifold Valves

Manifold Valves redefine fluid management

We are Manifold Valves manufacturers in Mumbai, India. A manifold is an essential component in fluid control systems, designed to efficiently manage the distribution and combination of fluids. Constructed from high-quality materials such as stainless steel, brass, aluminum, and various plastics, manifolds are built to withstand diverse operating conditions. They are used extensively across industries like oil and gas, chemical processing, water and wastewater treatment, HVAC, hydraulic systems, and pharmaceuticals.

Manifold Valves Advantages

Manifolds Valves offer numerous advantages, including improved flow control, reduced installation complexity, enhanced system organization, and minimized risk of leaks. They enable precise regulation of fluid distribution, ensuring optimal performance and reliability of connected systems. Available in various designs and configurations, manifolds can be tailored to meet specific application requirements, such as pressure regulation, flow path control, and fluid mixing.

Types Of Manifold Valves

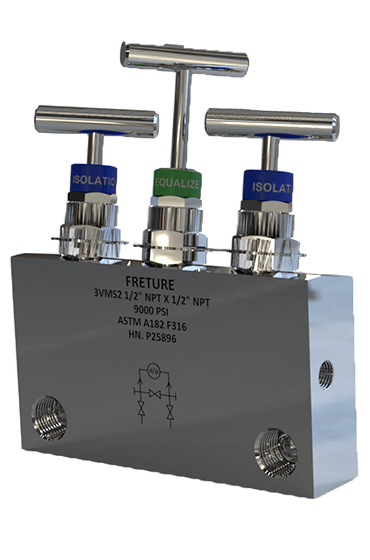

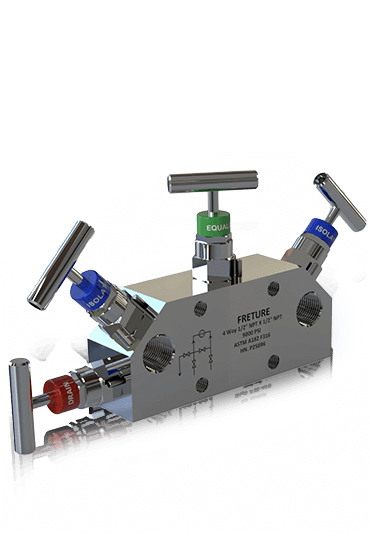

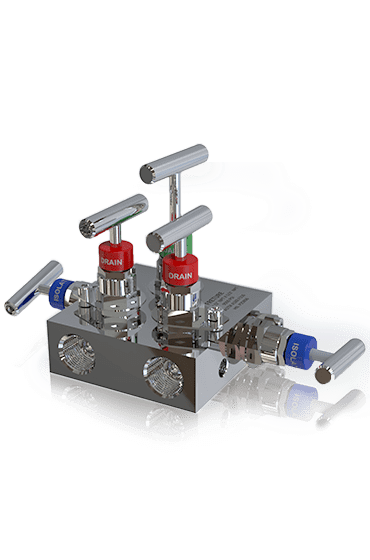

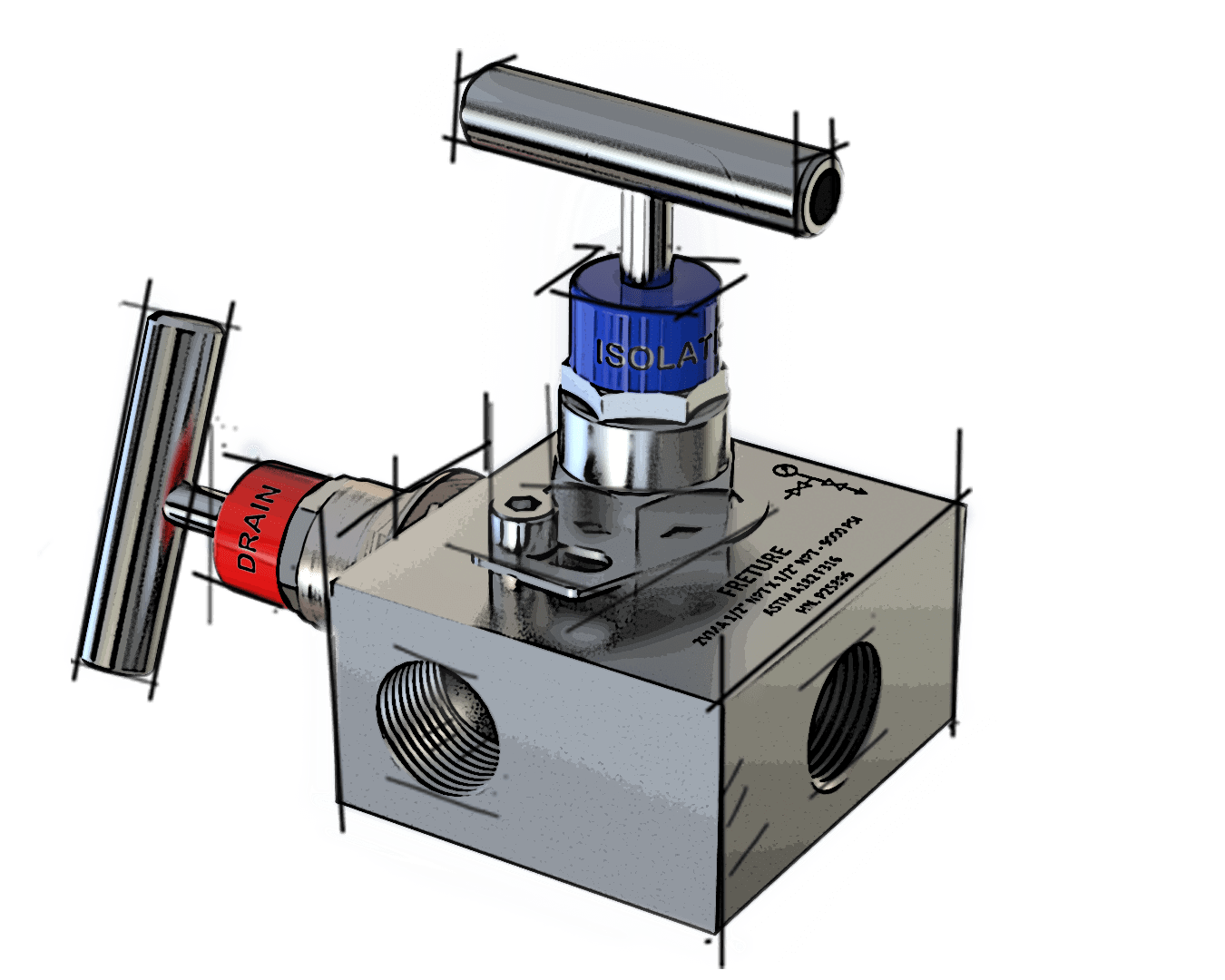

Choosing the right manifold involves considering factors like connection types such as 2 way manifold Valves , 3 way manifold Valves, 4 way manifold Valves and 5 way manifold Valves etc, material compatibility, operating pressure, and temperature conditions. With expert technical support and a commitment to quality, Freture provides manifolds that meet the highest industry standards, ensuring durability and efficiency in any industrial application.

Explore Types of Manifold Valves

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Manifold?

- How does it work?

Manifolds operate by directing fluid flow through a network of interconnected channels or ports. These channels are controlled by valves or other flow control devices, allowing for precise regulation of fluid distribution to various parts of a system.

- What are the main applications?

Manifolds are widely used in industries such as oil and gas, chemical processing, water treatment, HVAC systems, and hydraulic systems. They are essential in applications that require the distribution or combination of fluids, such as fuel delivery, chemical injection, and hydraulic power control.

- What are the benefits of using one?

The benefits of using a manifold include improved flow control, reduced installation time and complexity, enhanced system organization, minimized risk of leaks, and increased efficiency in fluid distribution. Manifolds also facilitate easier maintenance and troubleshooting.

- What materials are used in their construction?

Manifolds are typically constructed from materials such as stainless steel, brass, aluminum, and various plastics. The choice of material depends on factors like the type of fluid being handled, operating pressure, temperature conditions, and environmental considerations.

- How do I choose the right one for my application?

Choosing the right manifold involves considering factors such as the type and number of connections required, material compatibility with the fluid, operating pressure and temperature, and specific application requirements. Consulting with a knowledgeable supplier can help in selecting the most suitable manifold for your needs.

- Can they be repaired?

Yes, manifolds can often be repaired. Maintenance and repair may involve replacing seals, valves, or other components, as well as cleaning and reassembling the manifold. The extent of repairability depends on the design and the extent of wear or damage.

- What maintenance is required?

Maintenance of manifolds typically includes regular inspections, cleaning to prevent clogging, checking and replacing seals and valves as needed, and ensuring that all connections are secure. Preventive maintenance helps extend the lifespan of the manifold and ensures reliable performance.

- Are they available in different designs?

Yes, manifolds are available in various designs to meet different application needs. These designs can include different numbers and types of ports, various configurations for flow paths, and options for integrated control elements like valves and pressure regulators.

- Why is Freture the best place to buy from?

Freture is the best place to buy manifolds due to our commitment to providing high-quality products, expert technical support, competitive pricing, and exceptional customer service. Our manifolds are designed and manufactured to meet the highest industry standards, ensuring reliability, durability, and performance in diverse industrial applications.

Industries where Manifolds is used

Oil and Gas Industry

Chemical Processing Industry

Water Treatment Industry

HVAC system

Pharmacutical Industry

Applications of Manifold

- Fluid Distribution: They distribute fluids from a single source to multiple destinations, ensuring efficient flow management in various systems.

- Combining Fluid Streams: They combine multiple fluid sources into a single output, facilitating processes that require the mixing of different fluids.

- Pressure Regulation: They help regulate and maintain consistent pressure in fluid systems, ensuring optimal operation of connected components.

- Control of Flow Paths: They provide precise control over fluid flow paths, enabling the isolation and routing of fluids to specific areas as needed.

- Simplified Piping Systems: They reduce the complexity of piping systems by consolidating multiple connections into a single component, streamlining installation and maintenance.