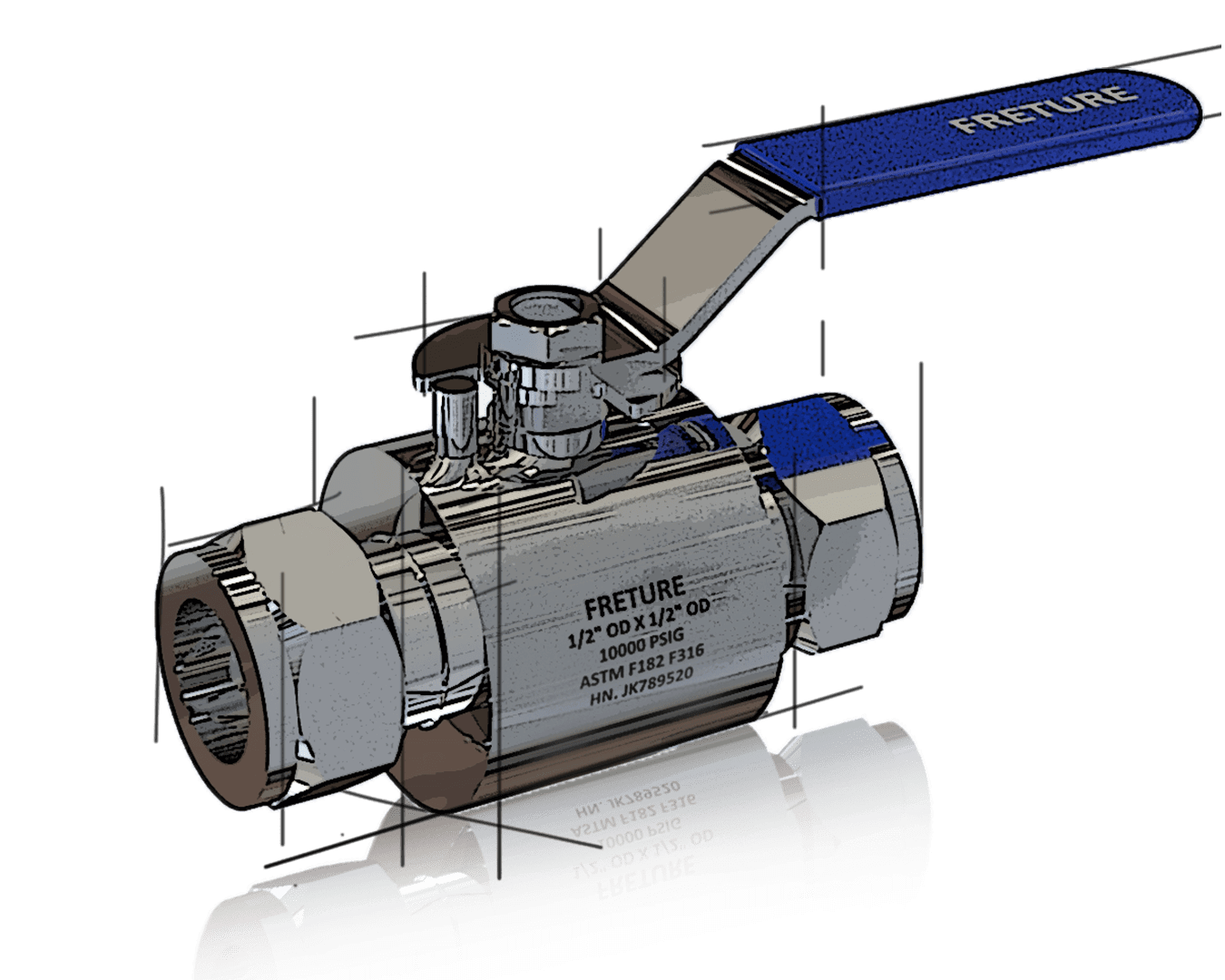

An instrumentation ball valve is a precision control device used to regulate the flow of fluids and gases in various industrial applications.

Instrumentation Ball Valve

Instrumentation Ball Valves (15000 psi (1000 bar) :Reliable Performance in High-Pressure Environments

We are a leading instrumentation Ball Valve manufacturer in Mumbai, India, dedicated to providing high-quality solutions for precision flow control. Instrumentation ball valves are meticulously engineered using top-grade materials such as Stainless Steel (SS316, SS304), PTFE, PFA, FEP. These materials ensure superior durability and corrosion resistance, making our valves ideal for demanding applications.

High Pressure Ball Valve Design Standards

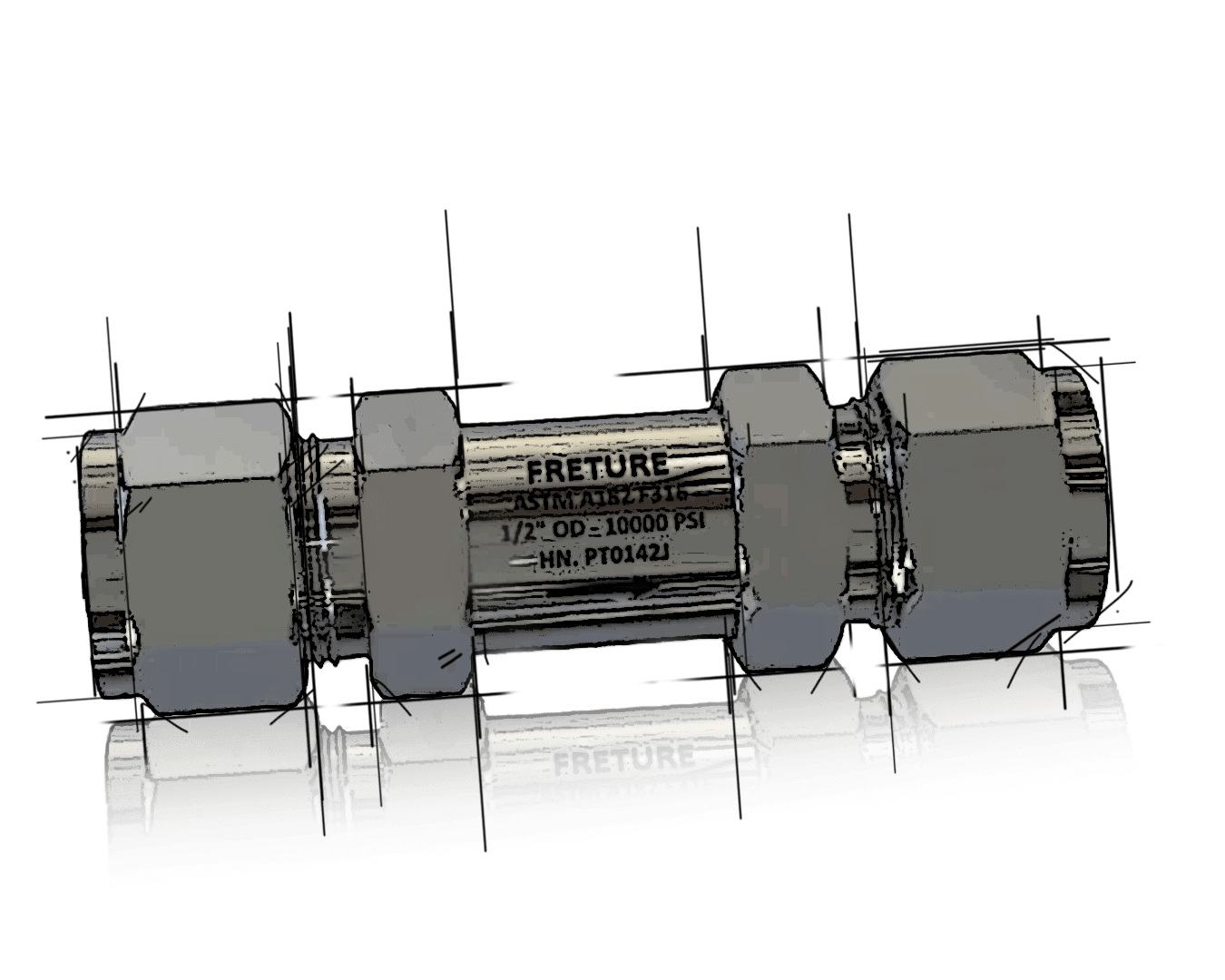

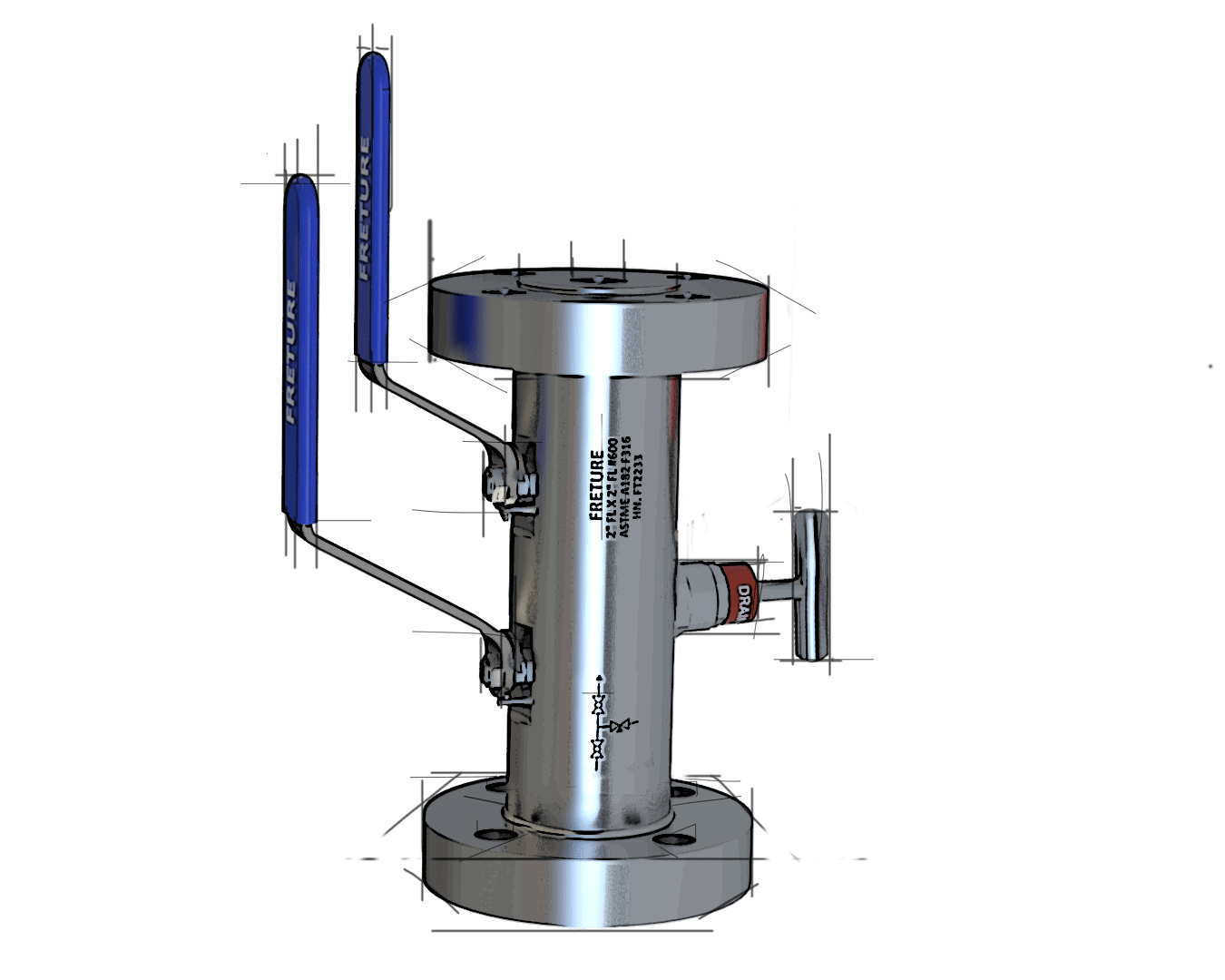

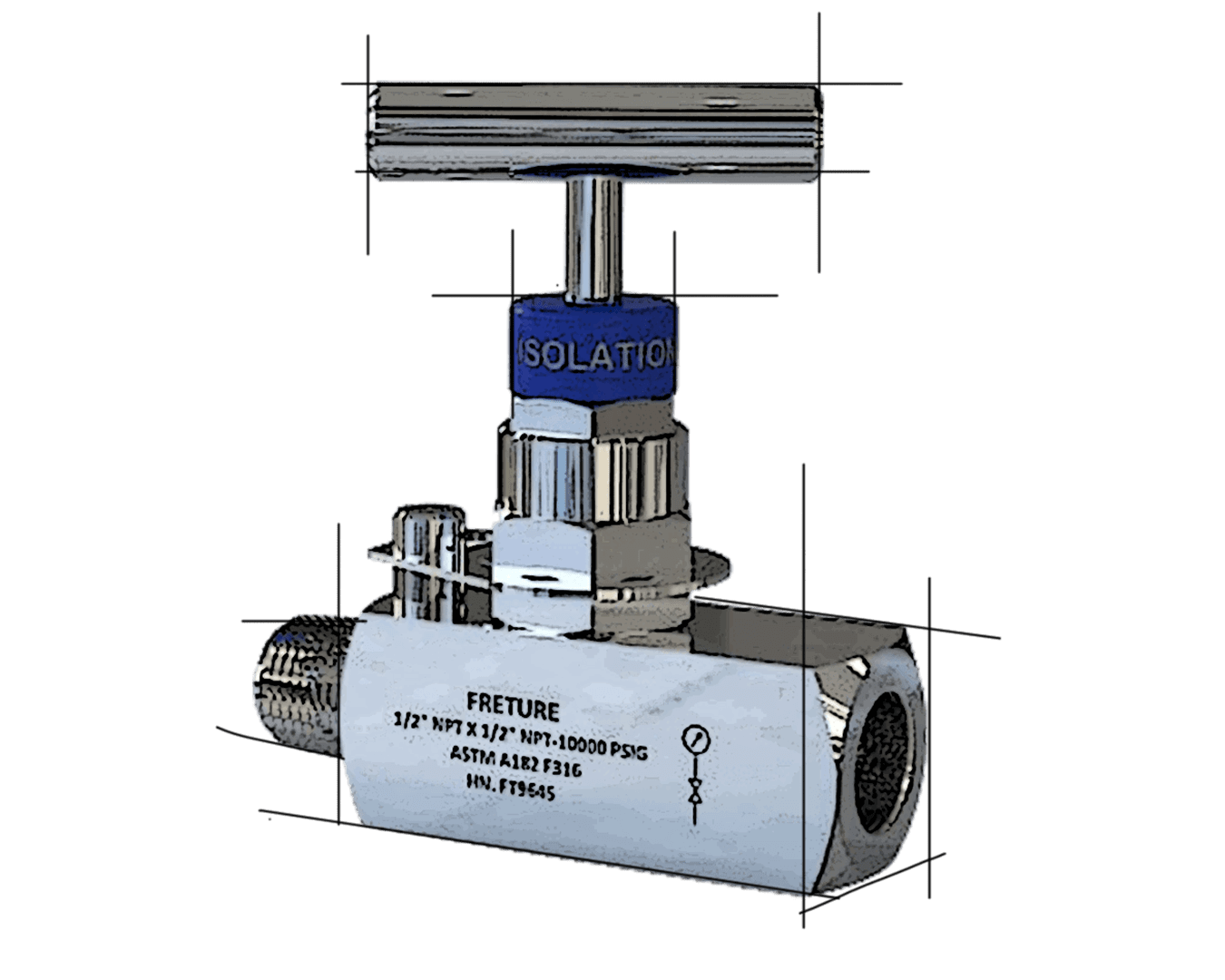

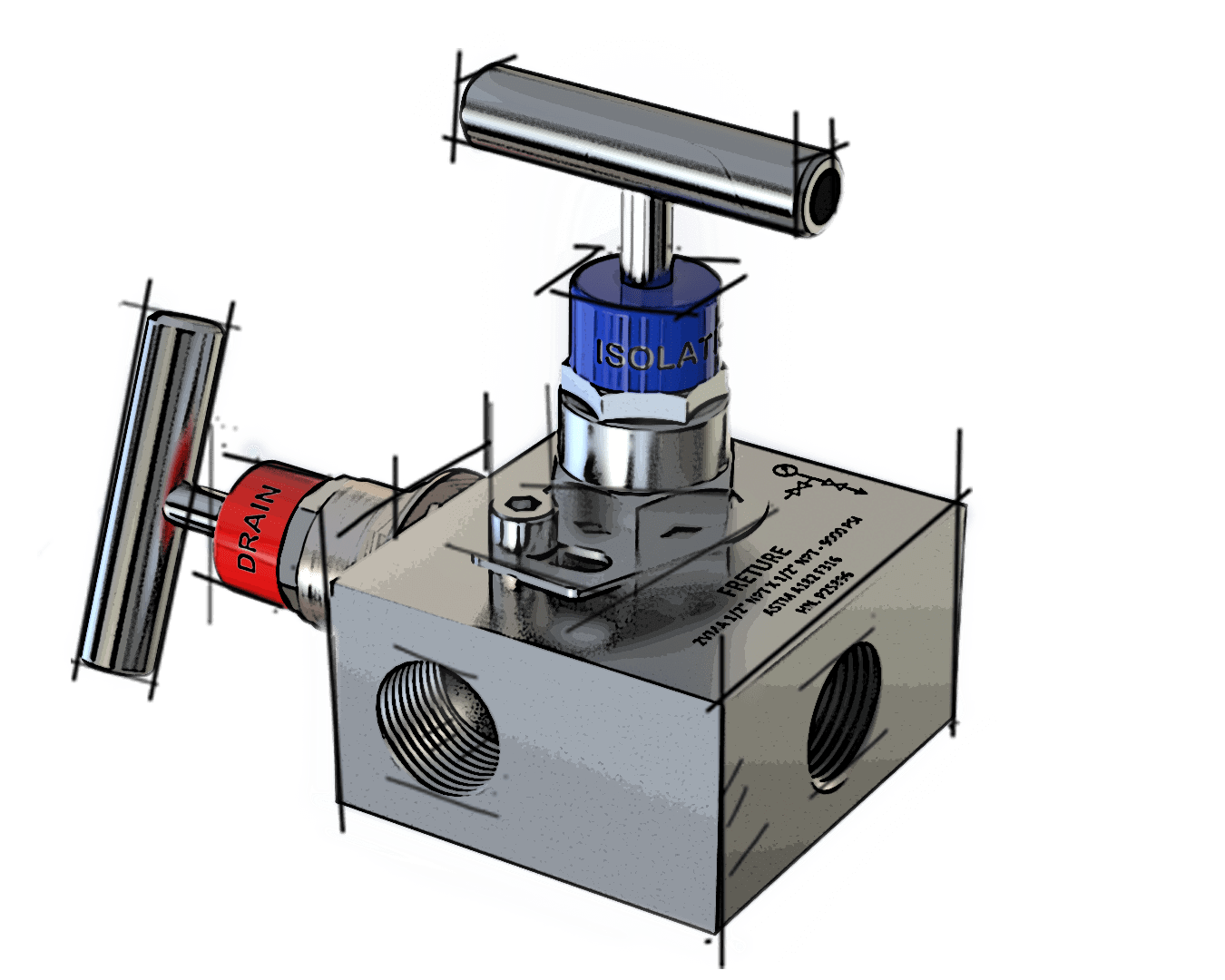

Ball valves are designed to operate under high pressures, up to 15000 psi (1000 bar), and can withstand a wide temperature range from (-120* C TO 500*C ) RANGE AS PER PRESSURE. They are available in various end connections, including threaded (NPT, BSPT, BSPP), welded (Butt Weld, Socket Weld), and flanged (ANSI, DIN), and come in sizes ranging from 1/4” to 2” (DN 6 to DN 50).

High Quality Ball Valve

Fretuer Techno high pressure ball valves are suitable for a broad range of applications, including the oil and gas industry, chemical processing, petrochemical plants, instrumentation systems, power generation, and the pharmaceutical industry. High Pressure Ball valves are built to meet rigorous manufacturing standards, including API 598, ISO 9001, and ASME B16.34, ensuring exceptional quality and reliability.

Choosing Fretuer means opting for precision, reliability, and durability. Instrumentation Ball valves feature bubble-tight shutoff for leak-proof performance, low operating torque for ease of use, and enhanced safety mechanisms. With a focus on innovation and customer satisfaction, we provide customized solutions tailored to meet specific application requirements.

Description | Features |

|---|---|

TYPE: One Piece / Two Piece / Three Piece End Connection: Threaded: NPT, BSPT, BSPP / Welded: Butt Weld, Socket Weld / Flanged: ANSI, DIN Size: 1/4” to 2” (DN 6 to DN 50) Pressure Rating: Up to 15000 PSI (1000 bar) Temperature Range: (-120* C TO 500*C )RANGE AS PER PRESSURE Body Materials: Body: Stainless Steel (SS316, SS304) / Ball: Stainless Steel (SS316) / Seats: PTFE (Teflon), PEEK / Seals: PTFE, Viton, or Buna-N Design Standard: API 598 (Valve Inspection and Testing) / ISO 9001 (Quality Management Systems) / ASME B16.34 (Valves – Flanged, Threaded, and Welding End) Face to Face: ASME B16.10 Rev 2009 Safety: NACE MOR 0175, BS/EN 10204-3.1 REV 2004, API 598 Rev 2009, API-607 |

|