A Gate Valve is a type of valve used to control the flow of fluid by either fully opening or fully closing the passageway with a sliding gate.

Gate Valve

Manufacturers of precision Gate Valves in India - Control media flow by raising and lowering the gate for seamless regulation.

We are leading Gate Valve manufacturers, suppliers and exporters in Mumbai, India. The straight-through unobstructed path of a gate valve causes low-pressure loss across the valve. Unlike butterfly valves, the unobstructed bore of a gate valve allows for pigs passage during cleaning pipe procedures. Gate valves come in a variety of sizes, materials, temperature and pressure ratings, and gate and bonnet designs.

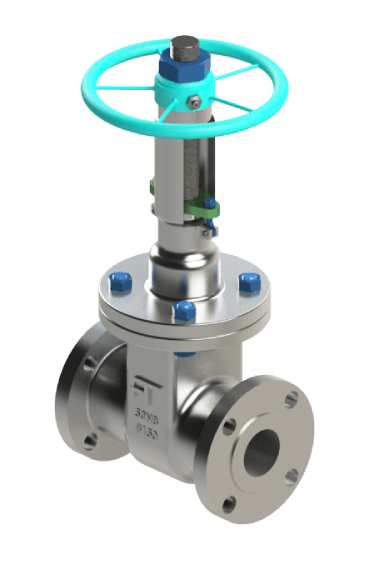

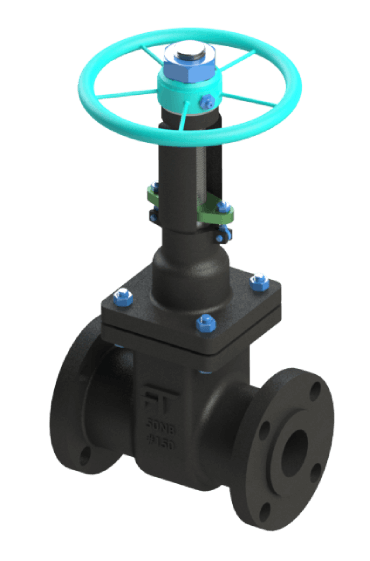

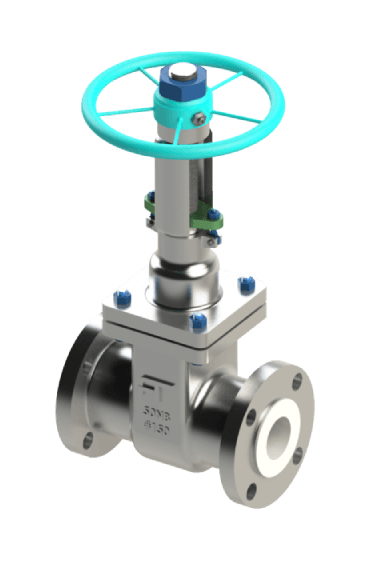

At Freture Techno Pvt. Ltd., we deliver gate valves that embody precision engineering and robust performance, tailored to meet the most demanding industrial requirements. Our gate valves are meticulously crafted to offer reliable flow control across a wide range of applications, ensuring efficiency and durability. Types of Gate Valve we provide API 600 Gate Valve, Forged Gate Valve and PTFE Lined Gate Valve

API Standard Compliance

Our gate valves are designed in accordance with API (American Petroleum Institute) standards, particularly API 600 Gate Valve and API 602. This adherence ensures that each valve meets the highest industry benchmarks for quality and operational reliability. By following these rigorous standards, we guarantee that our valves perform optimally under high-pressure and high-temperature conditions, providing you with exceptional safety and longevity.

Materials of Construction (MOC)

We offer Gate valves in a variety of materials to address diverse operational needs: Carbon Steel: Chosen for its strength and durability, making it suitable for general service applications. Stainless Steel: Provides excellent resistance to corrosion, ideal for challenging environments. Alloy Steel: Designed to withstand high temperatures, making it suitable for demanding applications. Special Alloys: Engineered for specific applications requiring unique material properties. Each material is selected to enhance the valve’s performance and longevity, ensuring it meets the specific requirements of your application.

Application Details

Gate valves are pivotal in industries requiring precise flow control with full shut-off capability. They are commonly used in: Oil and Gas: For managing the flow of hydrocarbons in pipelines and refineries. Water Treatment: In water distribution and wastewater management systems. Power Generation: Within steam and cooling water systems in power plants. Chemical Processing: For handling corrosive and high-temperature fluids in chemical plants. Our gate valves are engineered to deliver reliable operation, minimal pressure drop, and efficient flow control in these critical applications.

Explore Types of Gate Valves

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Gate Valve?

- How does it work?

It operates by raising or lowering a gate (a solid wedge or a flexible disc) to allow or block the flow of fluid through the valve.

- What are the main applications?

Gate Valves are commonly used in various industries including oil and gas, water and wastewater treatment, chemical processing, power generation, and mining.

- What are the benefits of using one?

The benefits include precise flow control, minimal pressure drop, tight sealing, and the ability to operate in high-pressure and high-temperature environments.

- What materials are used in their construction?

Gate Valves are typically constructed from materials such as cast iron, ductile iron, carbon steel, stainless steel, brass, or bronze. The internal components such as the gate and seat can be made of materials like stainless steel, brass, or bronze.

- How do I choose the right one for my application?

Choose based on factors such as the type of fluid, pressure rating, temperature range, valve size, end connections, and compatibility with specific application requirements.

- Can they be repaired?

Yes, Gate Valves can be repaired by replacing damaged components such as the gate, stem, or seat.

- What maintenance is required?

Regular maintenance includes lubrication of moving parts, inspection of seals and gaskets, and periodic testing to ensure proper operation.

- Are they available in different designs?

Yes, Gate Valves are available in various designs including rising stem, non-rising stem, wedge gate, and parallel gate designs to suit different application needs.

- Why is Freture the best place to buy from?

Freture is the preferred choice for purchasing Gate Valves due to our commitment to quality, extensive industry experience, and dedication to customer satisfaction. We offer a wide range of high-quality valves, expert technical support, competitive pricing, and tailored solutions to meet your specific needs.

Industries where Gate Valve is Used

Oil and Gas Industry

Wastewater Treatment

Chemical Processing

Power Generation Industry

Refineries

Application of Gate Valve

Oil and Gas Industry: Controls the flow of crude oil, natural gas, and other hydrocarbons in pipelines and refineries.

Water and Wastewater Treatment: Regulates the flow of water and wastewater in treatment plants, reservoirs, and distribution systems.

Chemical Processing: Manages the flow of various chemicals and corrosive fluids in chemical manufacturing plants.

Power Generation: Controls the flow of steam and cooling water in power plants for electricity generation.

Mining Industry: Handles the flow of slurry, water, and other materials in mining operations such as ore processing and mineral extraction.