It is a device used to regulate airflow in HVAC and industrial systems, providing precise control over air intake.

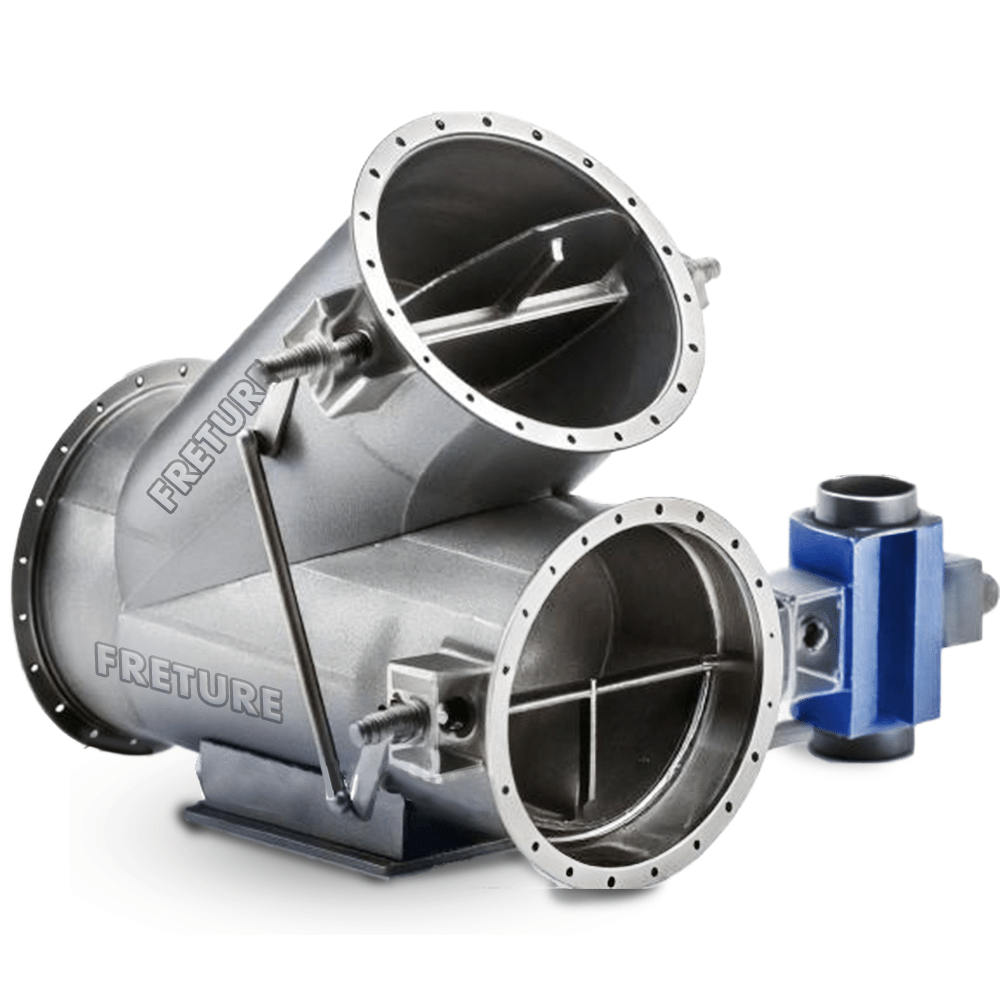

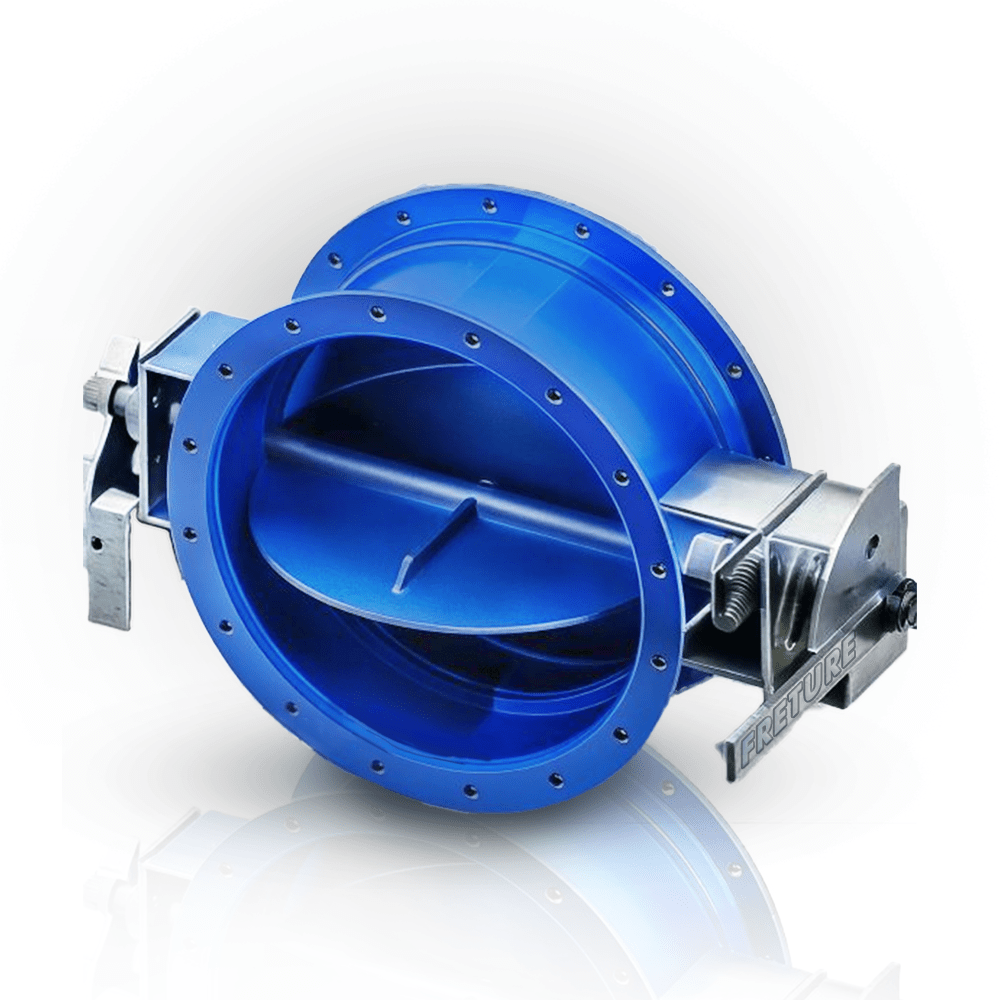

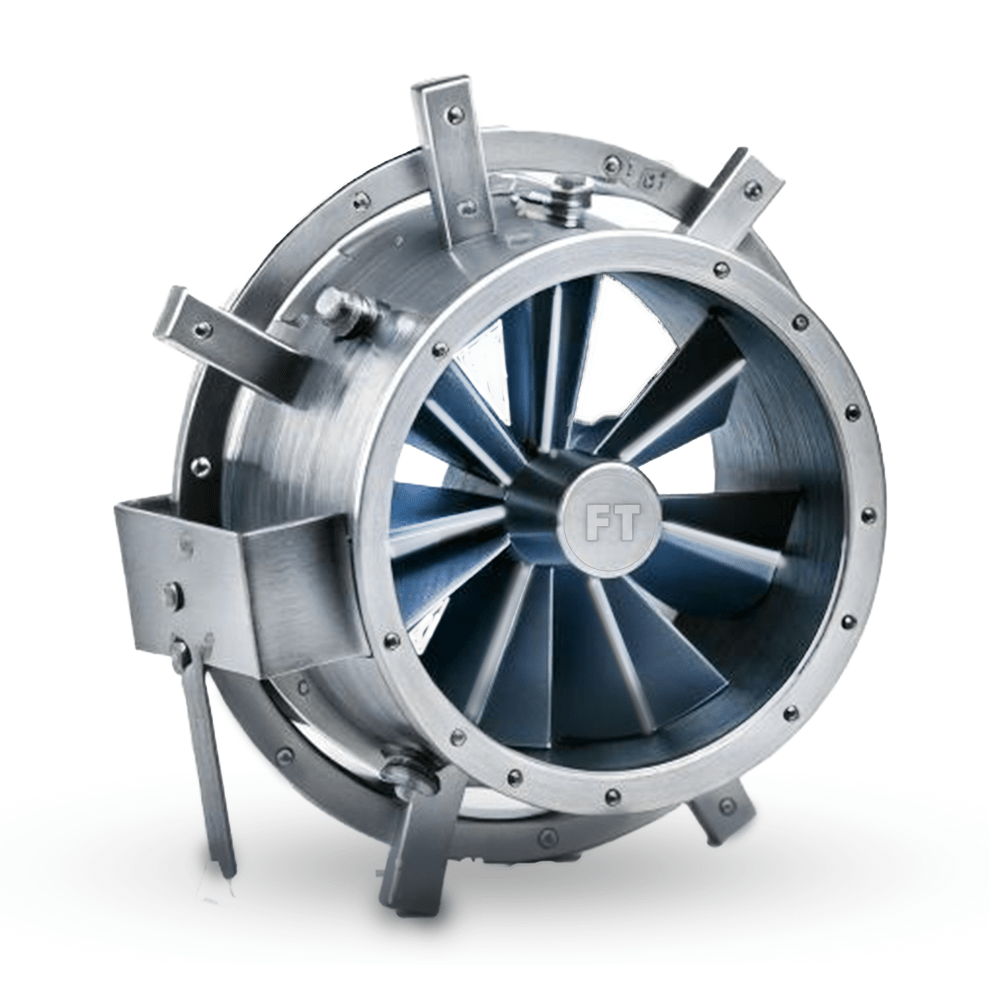

Inlet Vane Dampers

Regulate airflow efficiently for optimal system performance.

We are leading Inlet Vane Damper manufacturer in Mumbai, India, offering innovative solutions for airflow control in industrial and HVAC applications. Inlet Vane Dampers are devices used to regulate the volume and direction of airflow into fans and air handling systems. These dampers consist of a series of adjustable vanes mounted at the fan inlet, which can be adjusted to control the air volume or pressure entering the system.

These dampers work by varying the angle of the vanes, which alters the flow of air and helps maintain the desired system performance. By adjusting the vanes, the damper can modulate airflow, reduce fan power consumption, and optimize energy usage, especially in systems operating at varying loads. Inlet Vane Damper are often used to prevent overloading of fans, reduce startup energy requirements, and improve overall system efficiency. They are available in various materials and sizes to meet specific system requirements and environmental conditions.

Specifications | Features |

|---|---|

Type : Inlet Vane Damper End Connection: Flanged or Welded (Customizable) Size: Small to Large Diameter Ranges Class: Class 1, Class 2, Class 3 Temperature Range: -20°C to 400°C (Depending on Material MOC: Mild Steel (MS), Stainless Steel (SS), or Custom Design Standard: ASME, API, and Other International Standards Cycle Life: Over 100,000 Cycles Face to Face: Customizable Operation: Manual, Pneumatic, or Electric Actuator Fire safe design: Available Testing: Performance, Durability, and Safety Tested |

|

Related Products

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is an inlet vane damper?

- What materials are used in the construction of these dampers?

They are typically made from Mild Steel (MS), Stainless Steel (SS), or other materials based on the application and environmental conditions.

- How does these damper operate?

It can be operated manually, pneumatically, or electrically, depending on the system requirements.

- What is the maximum temperature that these Damper can handle?

They are designed to handle temperatures ranging from -20°C to 400°C, depending on the material of construction.

- Can these dampers be customized?

Yes, we provide customizable in terms of size, material, and operation type to fit specific industrial and HVAC applications.

- What standards are followed during manufacturing?

They are designed and manufactured in accordance with international standards like ASME, API, and others.

- What is the cycle life of these dampers?

They are built for long-lasting performance, with a cycle life exceeding 100,000 cycles.

- Are fire-safe designs available for these dampers?

Yes, fire-safe designs are available for critical applications, ensuring safety and compliance with industry standards.

- Do you offer documentation for the dampers?

Full documentation, including technical drawings, testing reports, and certifications, is provided with each damper.

- What industries use these Dampers?

They are used in a wide range of industries, including HVAC, power plants, industrial ventilation, and more.

Industries where Inlet Vane Damper is used

HVAC & Building Ventilation

Power Generation

Oil & Gas Industry

Chemical Industry

Pharmaceutical Industry

Applications

- Air Handling Units (AHUs) – Controls air intake for ventilation efficiency.

- Cooling Tower Airflow Control – Improves heat exchange performance.

- Food Processing Plant Air Handling – Maintains hygiene and airflow balance.

- Boiler Combustion Air Control – Regulates air supply for efficient combustion.

- Incineration Airflow Adjustment – Enhances efficiency in waste treatment.

- LNG Terminal Ventilation – Ensures controlled airflow in cryogenic storage areas.